Skate Wheel Conveyor vs Roller Conveyor

When it comes to selecting conveyors for loading and unloading operations, Skate Wheel Conveyors and Roller Conveyors are two of the most popular options. Both serve similar purposes, yet each type brings unique advantages and features.

Related Products

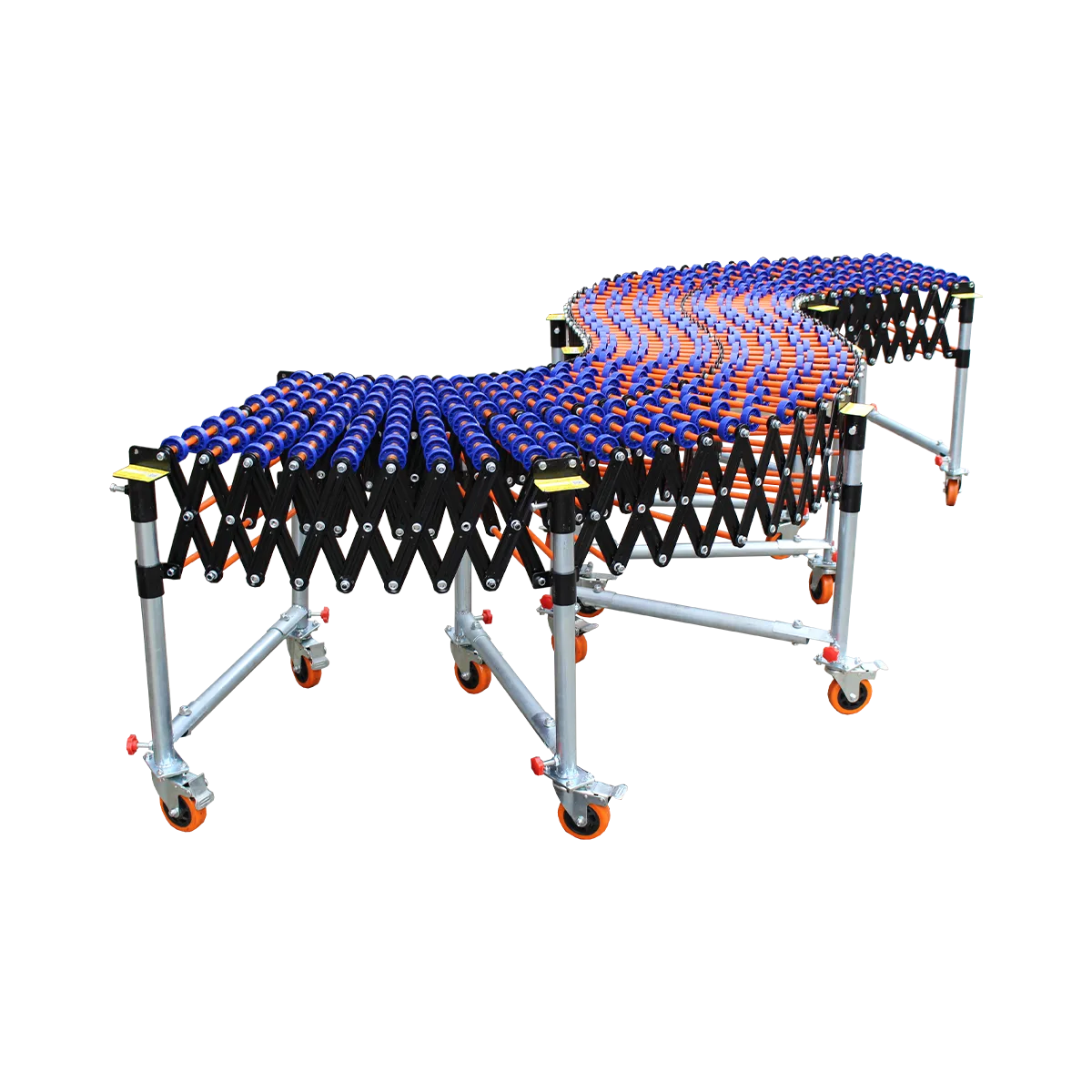

- Gravity Skate Wheel Conveyor – 2100 mm/SectionCollapsed Length

420 mm

Extended Length2100 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

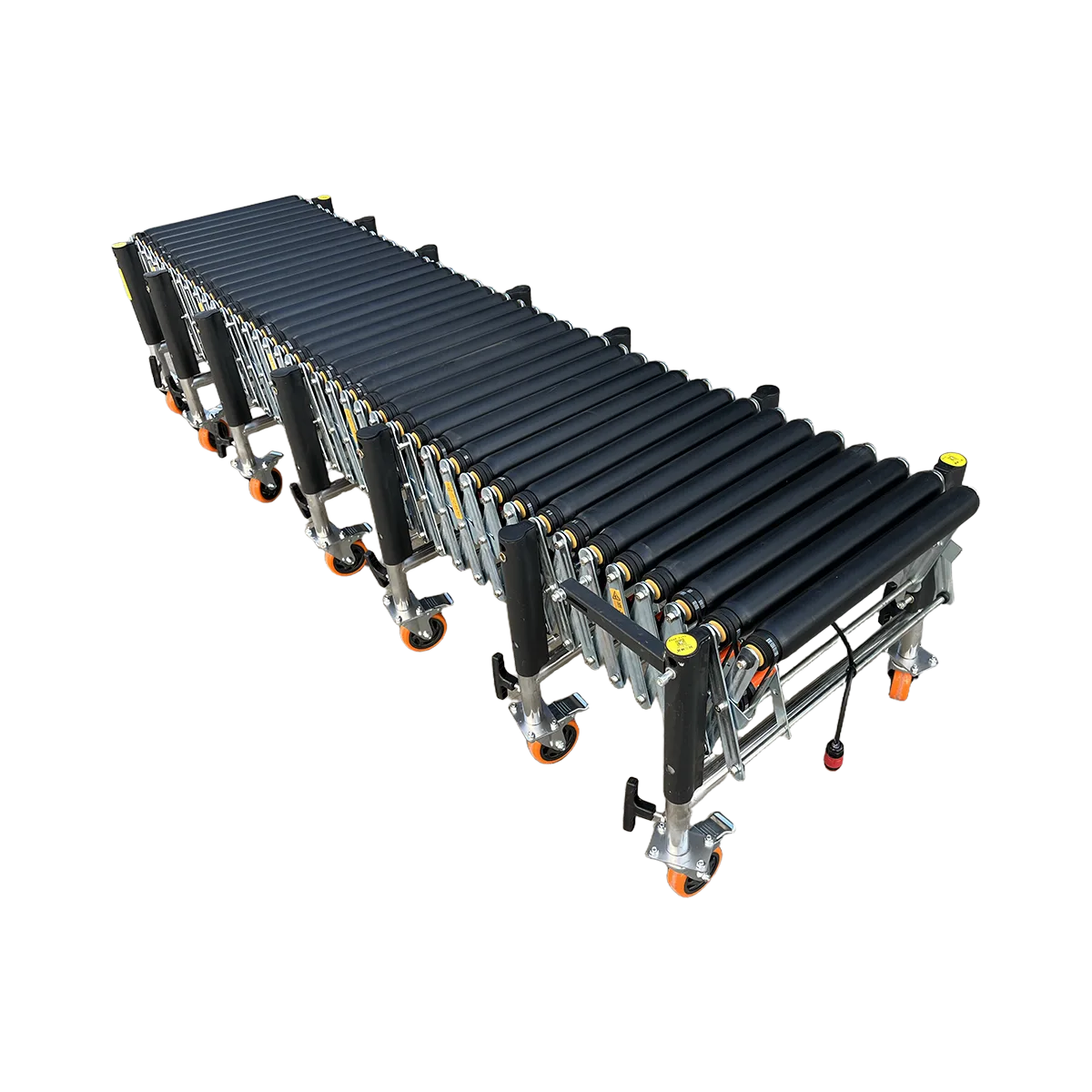

- Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

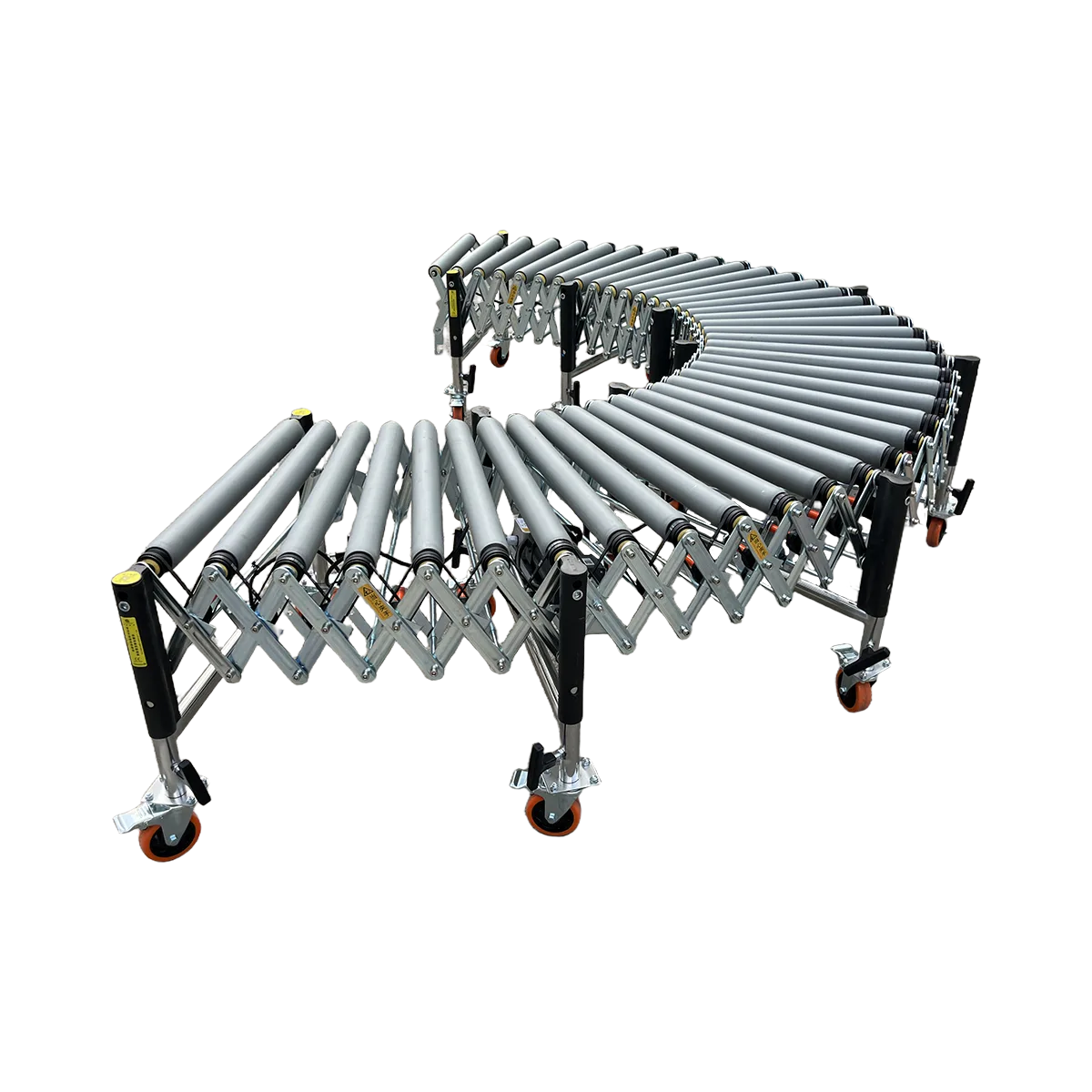

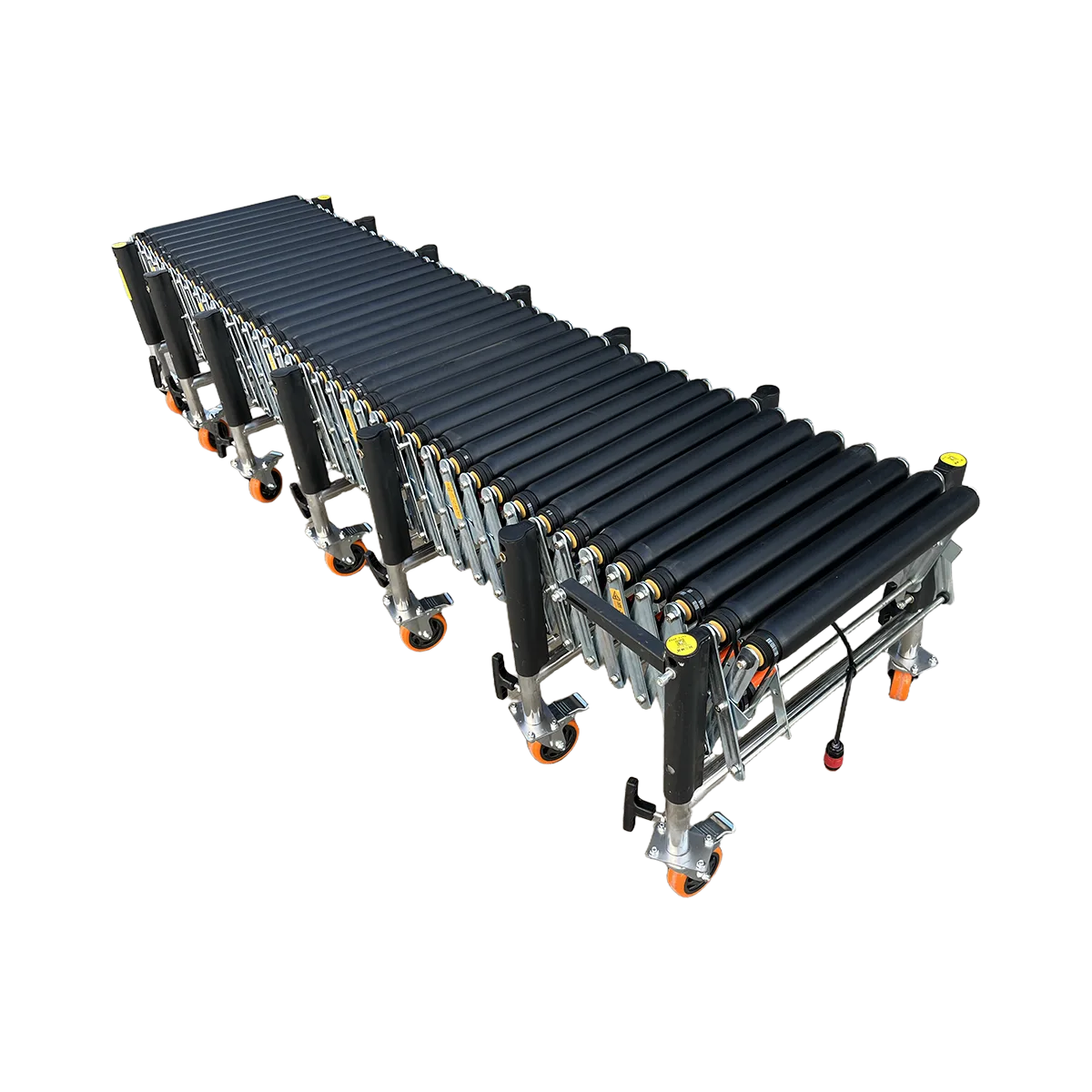

- Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

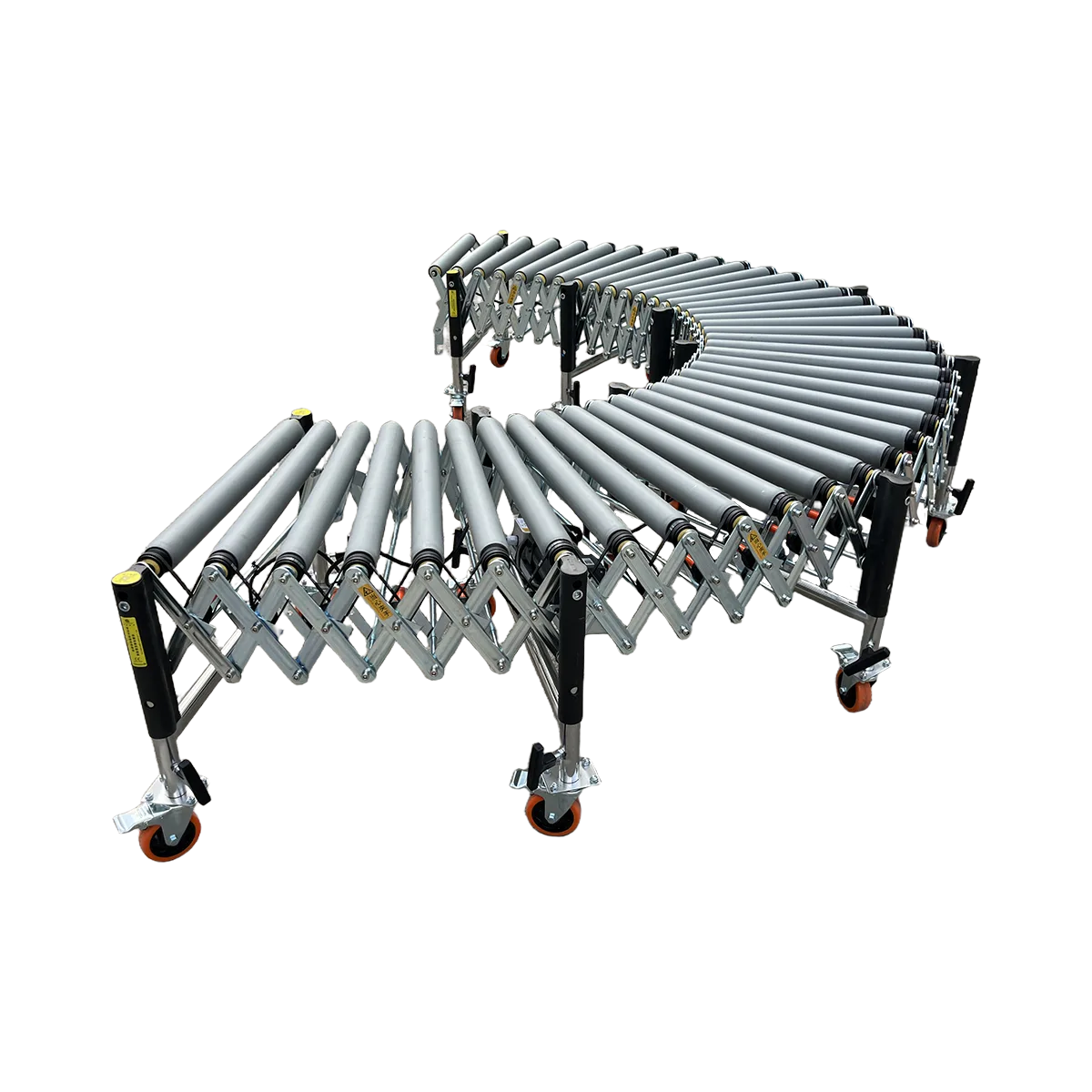

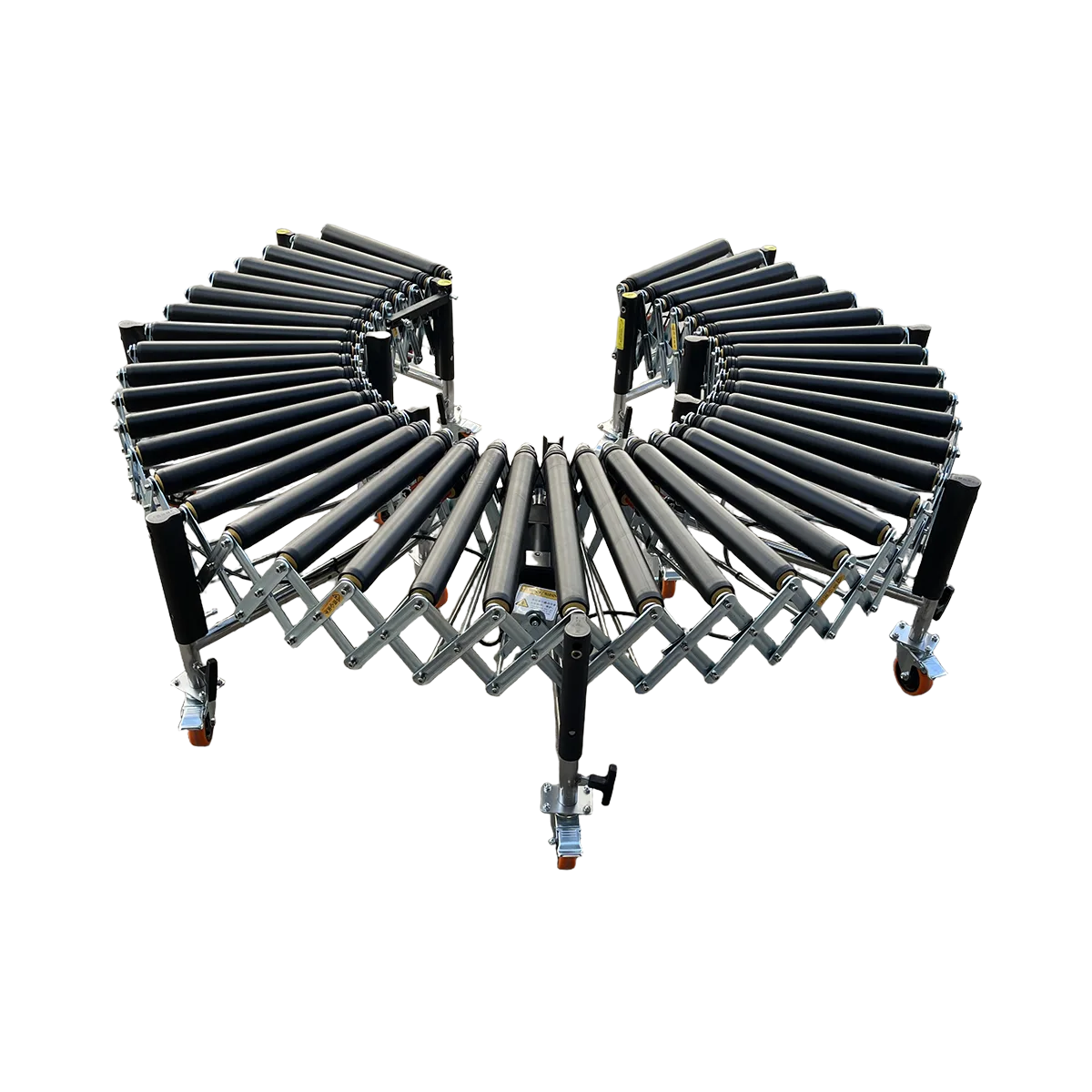

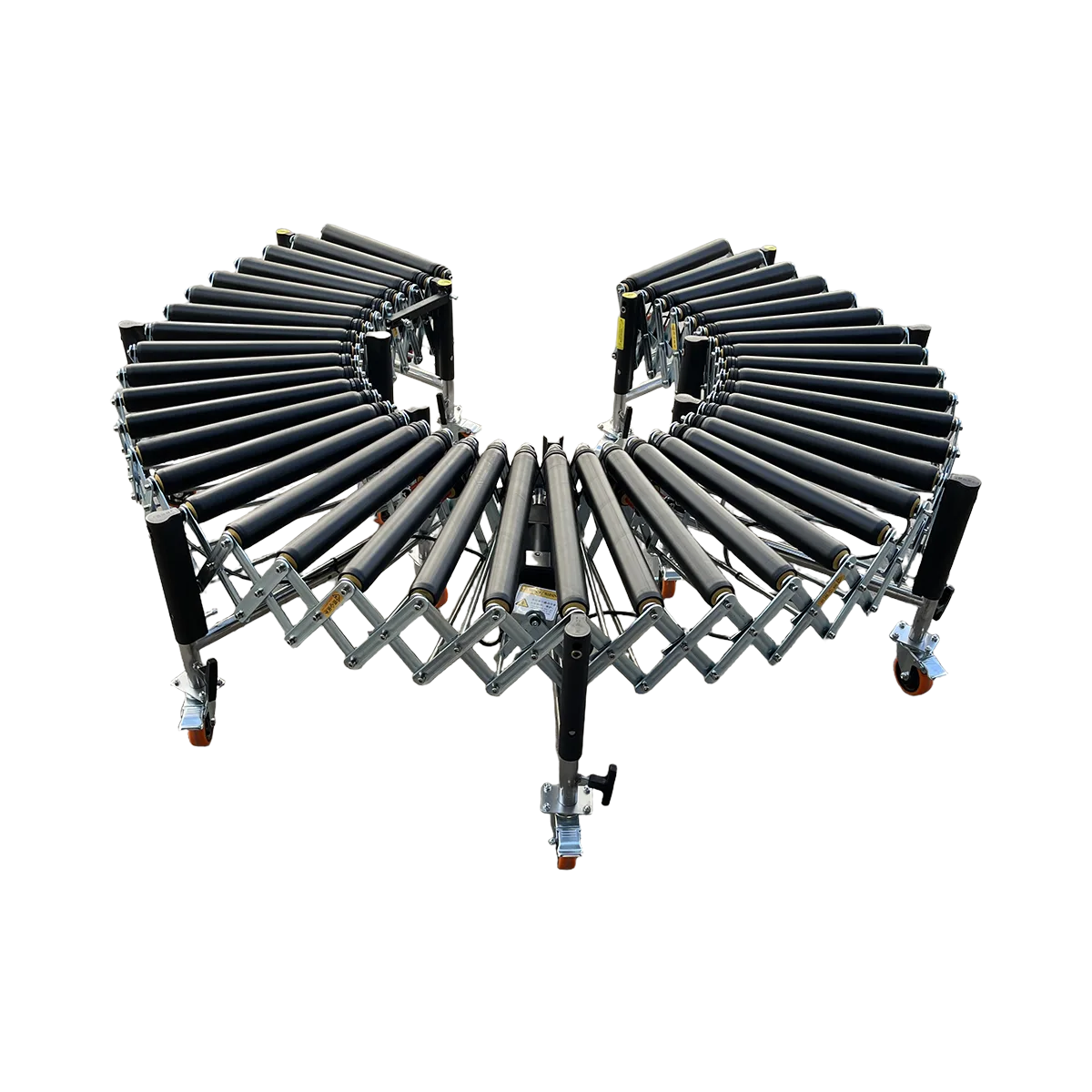

- Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

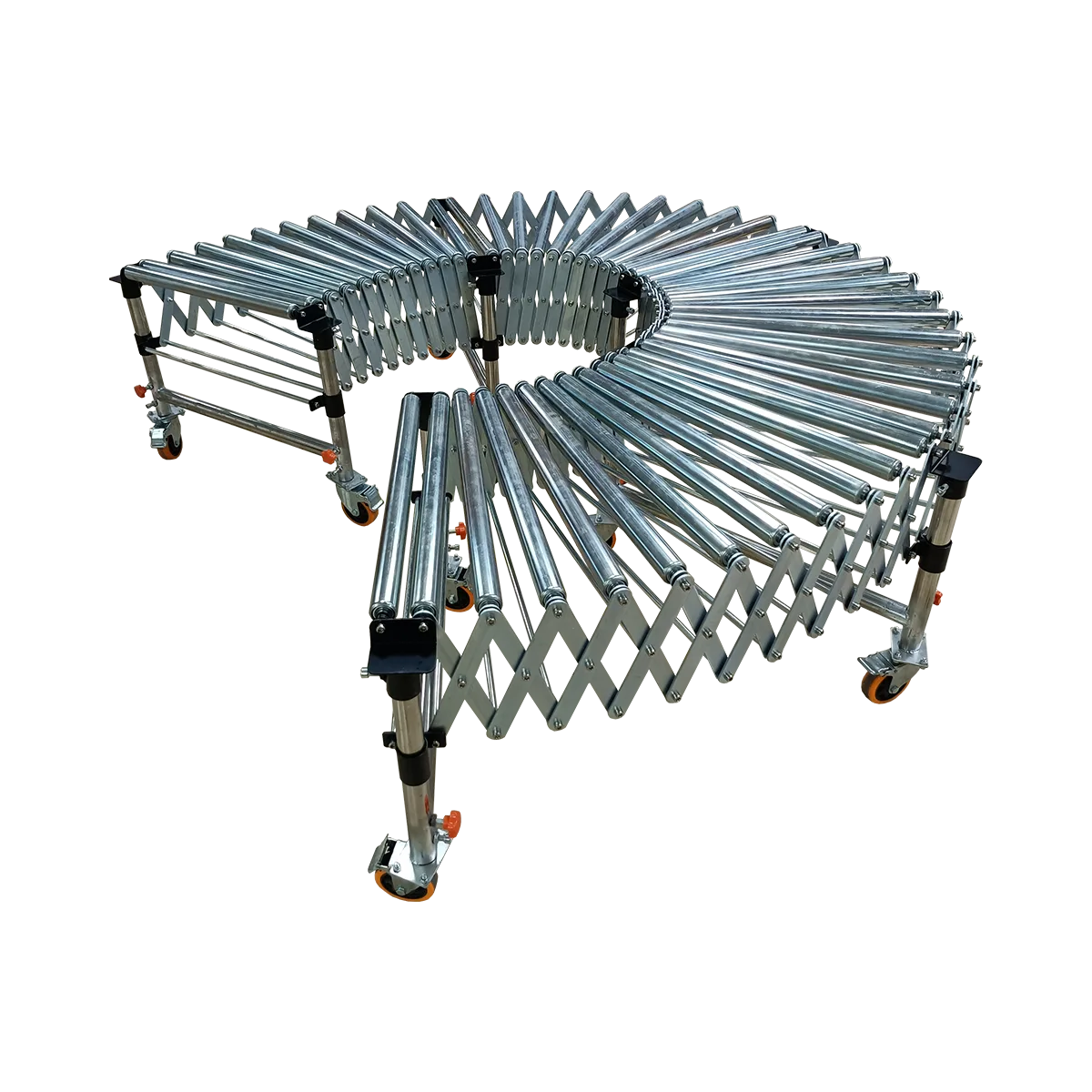

- Gravity Roller Conveyor – Roller Diameter 50 mm – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

When it comes to selecting conveyors for loading and unloading operations, Skate Wheel Conveyors and Roller Conveyors are two of the most popular options. Both serve similar purposes, yet each type brings unique advantages and features. This comparison will examine key parameters, differences, and help you decide which option is best suited for your logistics, truck loading/unloading, or warehouse operations.

The following is a comparison table between Skate Wheel Conveyor and Roller Conveyor to help you understand the difference between the two conveyors more clearly:

| Feature | Skate Wheel Conveyor | Roller Conveyor |

| Type | Gravity or Manual | Powered or Gravity |

| Load Capacity | 50kg per meter | 80kg–100kg per meter |

| Application | Unloading lightweight goods | Loading and unloading heavy goods |

| Design Flexibility | Expandable, Adjustable, Mobile, Foldable | Expandable, Adjustable, Mobile, Foldable |

| Suitable for | Flat-bottomed items, light packages | Bulkier, heavier items, bags, irregular shapes |

| Ease of Use | Lightweight, simple setup | More robust, requires power for heavy loads |

| Space Efficiency | Compact, easy to store | Takes up more space, but versatile |

| Cost | More affordable | Higher cost due to durability and functionality |

| Inclined Transport | Not ideal for inclined use | Can be used both horizontally and inclined |

| Rubber Rollers | Not available | Available for handling uneven or slippery loads |

| Best for | Short-distance unloading of light goods | Heavy-duty loading and unloading operations |

This comparison chart can help you more quickly determine which conveyor is right for your needs.

Advantages of Skate Wheel Conveyors

Skate Wheel Conveyors are simple yet effective systems, ideal for lightweight goods and applications requiring flexibility. They are often gravity-powered and require little maintenance. Skate wheels roll freely, making them perfect for transferring flat-bottomed boxes. They are more lightweight and affordable than roller conveyors, with a maximum load of 50kg per meter.

Roller Conveyors: More Heavy Duty and Versatile

Roller Conveyors, on the other hand, are robust systems suited for more extensive operations. They are more durable and capable of handling heavier loads, ranging from 80kg to 100kg per meter. These conveyors can be powered or gravity-fed, offering flexibility for both loading and unloading processes.

Flexibility in Design and Usage

Both systems are expandable, flexible, and mobile, making them versatile for different operational setups. However, roller conveyors tend to offer more versatility in terms of handling various load types and directions. Powered roller conveyors allow for horizontal and inclined transportation of heavier products, while skate wheels are typically used on flat surfaces.

Skate Wheel Conveyor: Ideal for Unloading

Since Skate Wheel Conveyors are gravity-powered, they are best suited for unloading applications, particularly when handling lighter, flat-bottomed items. Their ability to fold and adjust to various lengths makes them an excellent choice for confined spaces or temporary setups.

Roller Conveyor: Suitable for Both Loading and Unloading

Roller Conveyors, especially powered versions, are capable of both loading and unloading. They can handle larger loads and more challenging items, including bags and bulky goods, thanks to their ability to adjust in direction and functionality. Whether horizontal or inclined, these conveyors can accommodate heavier cargo with ease.

Cost Efficiency: Skate Wheel vs Roller Conveyor

Skate Wheel Conveyors tend to be more affordable due to their simpler structure and lighter materials. However, if you require a more durable, heavy-duty solution that can handle larger volumes and heavier weights, a roller conveyor may offer a better return on investment in the long term.

Weight Handling Capacity Comparison

A notable distinction between the two is their load-bearing capacity. Skate Wheel Conveyors typically handle lighter items (up to 50kg per meter), making them ideal for smaller operations or unloading tasks. Roller Conveyors, with their higher weight tolerance (up to 100kg per meter), are better suited for industries needing robust systems capable of managing larger, heavier products.

Flexibility in Conveyor System Configuration

Both systems offer expandable and flexible designs, but roller conveyors can be better adapted to different inclines, while skate wheels are more suited for flat surfaces. Roller conveyors also provide more options in terms of customization and configuration for various materials and sizes of products.

Rubber Roller Conveyors: A Special Case

For operations involving uneven loads or bags, Rubber Roller Conveyors offer an advantage. They prevent goods from slipping and provide extra stability, making them ideal for items that could otherwise slide off a skate wheel conveyor. This makes rubber roller conveyors particularly valuable for industries that handle diverse goods with different shapes.

FAQs

What’s the main difference between Skate Wheel and Roller Conveyors?

Skate Wheel Conveyors are lightweight and best for flat-bottomed, lighter goods, while Roller Conveyors are more durable and capable of handling heavier, bulkier loads.

Can Skate Wheel Conveyors be used for loading goods?

No, Skate Wheel Conveyors are best suited for unloading lighter items and work well on flat surfaces.

What are the weight limits for Skate Wheel and Roller Conveyors?

Skate Wheel Conveyors can handle up to 50kg per meter, while Roller Conveyors can carry between 80kg to 100kg per meter, depending on the model.

Are Roller Conveyors suitable for inclined transport?

Yes, powered Roller Conveyors are ideal for both horizontal and inclined transportation, offering more flexibility in handling heavier goods.

Why should I choose a Rubber Roller Conveyor?

Rubber Roller Conveyors are great for transporting bags or unevenly shaped goods as the rubber rollers prevent slipping and ensure stability.

Table of Contents

Recent Posts

Optimize hardware store logistics with the right building supply conveyor systems. Our guide to tool distribution systems enhances retail warehouse automation for efficient operations.

Optimize your medical supply logistics with efficient gravity conveyor systems. Learn how to safely handle healthcare products while improving your hospital supply chain operations.

Discover how a sports equipment conveyor system can streamline your athletic gear logistics. Flexible conveyor solutions for all shapes and sizes of sporting goods.