Bag Loading Conveyor – Transforming Efficiency in Bag Handling

In this comprehensive guide, we’ll explore the advantages of using different conveyor systems, particularly focusing on powered rubber roller conveyors, hydraulic conveyors, and telescopic conveyors. We’ll also compare these systems and help you make an informed decision based on your specific needs.

Related Products

- TeleScopic Conveyor – 4 SectionsCollapsed LengthExtended LengthLoad Capacity

60 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- TeleScopic Conveyor – 3 SectionsCollapsed LengthExtended LengthLoad Capacity

60 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Hydraulic Conveyor – Large – 7900 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Hydraulic Conveyor – Medium – 7000 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

In the fast-paced logistics world, every second counts. The traditional method of manual bag loading and unloading is not only time-consuming but also physically demanding. Bag loading conveyors offer an innovative solution, enhancing operational efficiency and cutting down on manual labor. In this guide, we’ll dive into the benefits of automated conveyors, comparing them with manual handling and explaining why conveyors like powered rubber roller conveyors, hydraulic conveyors, and telescopic conveyors are a game-changer.

Why Use a Bag Loading Conveyor System?

The need for automation in material handling is stronger than ever. Bag loading conveyors are specifically designed to make the loading and unloading of goods like sugar bags faster, safer, and more cost-effective. By automating the process, companies can reduce reliance on manual labor, minimize errors, and increase throughput.

Manual Handling vs. Conveyor Systems: A Time and Labor Comparison

Traditional Manual Handling

In a typical manual handling scenario, at least 4–6 workers might be required to load or unload a truck. One or two workers would need to climb into the truck to lift and move heavy bags, while others wait at the unloading platform to take the bags from them. The process is physically demanding and time-consuming, often leading to delays and inefficiencies. Moreover, the potential for injury increases with prolonged manual labor, especially when lifting heavy loads such as 50 kg sugar bags.

Conveyor Systems: Efficiency Redefined

Imagine this: with a bag loading conveyor system, the number of workers can be reduced to just two people. One person remains inside the cargo hold, while the other operates the conveyor at the unloading end. This significantly reduces the number of personnel needed, cutting down on labor costs. The powered rubber roller conveyor or hydraulic conveyor can automatically move bags to the unloading platform with minimal human intervention, streamlining the entire process.

In fact, automated conveyors can reduce the time spent on loading or unloading by up to 50% compared to manual handling. Not only is the process faster, but it also ensures that bags are handled more carefully, reducing the risk of product damage. This means fewer accidents, fewer damaged goods, and ultimately, more efficient operations.

Time and Labor Efficiency Comparison

| Process | Manual Handling | Conveyor System |

| Number of Workers | 4-6 | 2 |

| Time to Load/Unload (per truck) | 60-90 minutes | 30-45 minutes |

| Labor Costs | High (Multiple workers needed) | Low (Only 2 workers needed) |

| Risk of Injury | High (Manual lifting of heavy bags) | Low (Automated handling) |

| Risk of Product Damage | Higher (Manual handling errors) | Lower (Smooth conveyor operation) |

As shown in the table, using bag loading conveyors drastically reduces the number of workers, the time required to unload the truck, and the overall cost. The efficiency boost and safety improvements make conveyors a must-have for any business involved in high-volume material handling.

The Benefits of Powered Rubber Roller Conveyors

Why Choose Powered Rubber Roller Conveyors?

The powered rubber roller conveyor is ideal for handling soft and heavy goods like sugar bags. The rubber-coated rollers provide enhanced grip, ensuring that the bags are moved securely without slipping. Unlike traditional powered roller conveyors, which are less suitable for fragile or soft bags, the powered rubber roller conveyor minimizes the risk of product damage and provides smoother operation.

- Gentle Handling: The rubber rollers prevent bags from slipping, offering better control and minimizing damage to the bags.

- Increased Load Capacity: This system can carry up to 120 kg per meter, making it perfect for heavy-duty operations.

- Flexibility: It’s highly adaptable to different warehouse layouts, and you can adjust the conveyor’s length, height, and speed to suit various needs.

Hydraulic Conveyors and Their Role in Efficient Bag Loading

The hydraulic conveyor is an excellent choice for environments that require adjustable lifting heights, such as when unloading bags from trucks or containers at different heights. Combining a powered rubber roller conveyor with a hydraulic conveyor enhances flexibility in handling different bag sizes and weights.

Benefits of Hydraulic Conveyors:

- Height Adjustability: The hydraulic lift system makes it easy to adjust the conveyor height to match various truck bed heights.

- Heavy Load Handling: Hydraulic conveyors can support heavier loads, such as bulk sugar bags, ensuring smooth movement and preventing strain on workers.

- Flexibility and Efficiency: Combining this with a powered rubber roller conveyor ensures both adjustable height and secure handling of bags.

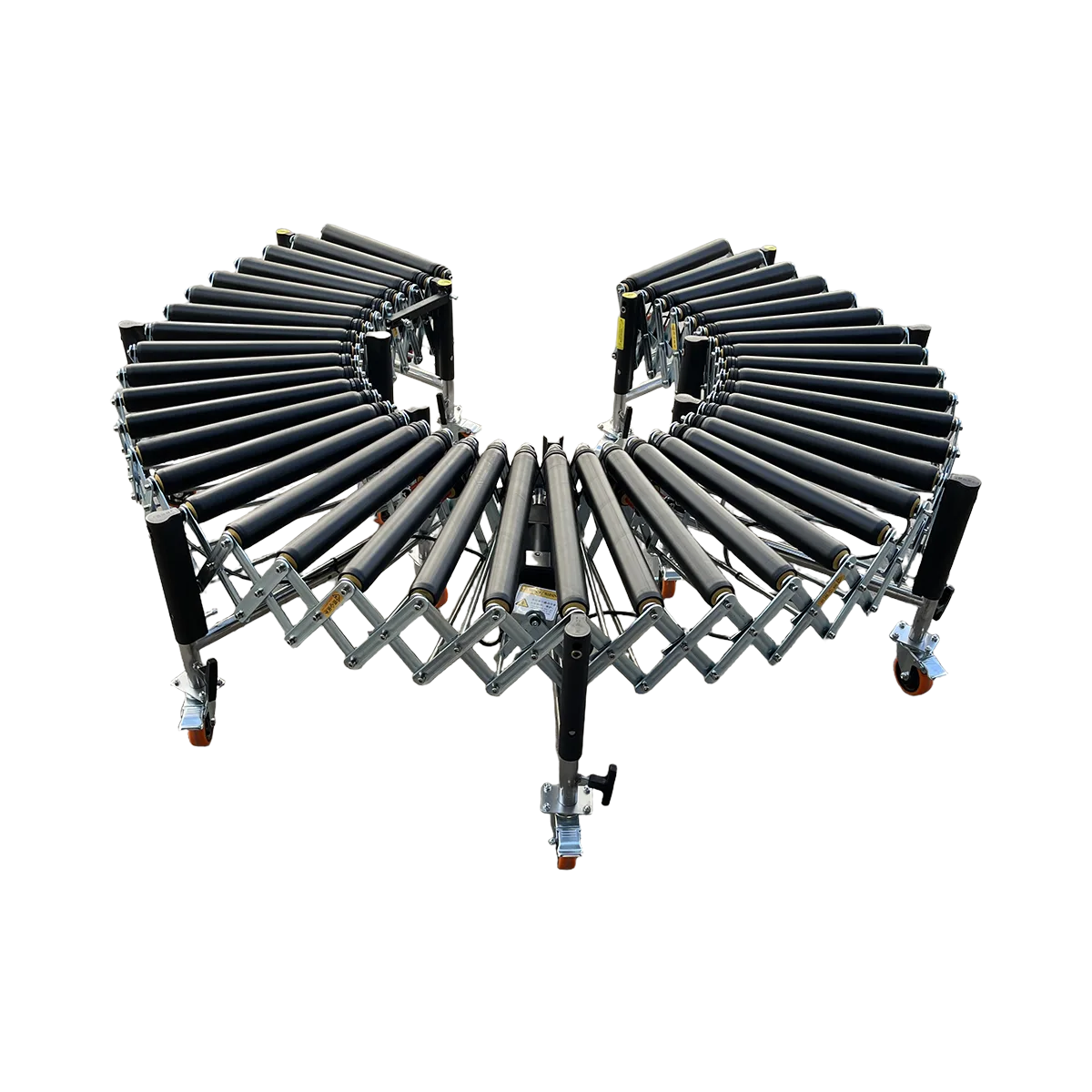

Telescopic Conveyors: Space-Saving Solutions for Fixed Platforms

If you’re dealing with a fixed unloading platform and space is a concern, a telescopic conveyor might be the perfect solution. This conveyor system is designed to extend and retract automatically, allowing for faster unloading while occupying minimal space.

Telescopic Conveyor Pros and Cons

| Feature | Powered Rubber Roller + Hydraulic Conveyor | Telescopic Conveyor |

| Adjustable Height | Yes (Hydraulic lift) | Yes (Manual or automatic extension) |

| Flexibility | Highly flexible for varying heights | Less flexible (fixed unloading platforms) |

| Space Requirement | Requires more space for height adjustments | Saves space (retractable design) |

| Speed of Operation | Moderate speed | High-speed unloading |

| Load Capacity | Up to 120 kg/m | Up to 80 kg/m |

| Cost | Lower | Higher |

Advantages of Telescopic Conveyors

- Space Efficiency: Telescopic conveyors retract to save space when not in use, making them ideal for warehouses with limited room.

- Quick Unloading: The automatic extension allows for rapid bag unloading, reducing the time needed for each operation.

Disadvantages of Telescopic Conveyors

- Fixed Unloading Area: Telescopic conveyors are best suited for unloading areas with fixed unloading platforms. If flexibility is needed for varying truck heights, a hydraulic conveyor might be a better choice.

- Lower Load Capacity: Telescopic conveyors typically handle lighter loads compared to the powered rubber roller + hydraulic conveyor combination, which is more suited for heavy-duty applications.

Conclusion: Why Choose Bag Loading Conveyors?

The right bag loading conveyor system can revolutionize your operations by reducing manual labor, saving time, and improving safety. When compared to traditional manual handling, automated conveyors significantly boost efficiency and reduce labor costs. Whether you opt for powered rubber roller conveyors, hydraulic conveyors, or telescopic conveyors, each type offers unique benefits tailored to different loading and unloading scenarios.

For businesses that need flexibility, the powered rubber roller conveyor combined with a hydraulic conveyor provides an efficient and versatile solution. For fixed unloading areas with space constraints, telescopic conveyors provide a space-saving, high-speed solution.

By switching to automated bag loading conveyors, you can improve efficiency, reduce labor costs, and enhance the safety of your operations, making it a worthwhile investment for any logistics or manufacturing operation.

Interested in finding the best conveyor solution for your needs? Contact us for a personalized consultation and optimize your material handling today!

Table of Contents

Recent Posts

Optimize hardware store logistics with the right building supply conveyor systems. Our guide to tool distribution systems enhances retail warehouse automation for efficient operations.

Optimize your medical supply logistics with efficient gravity conveyor systems. Learn how to safely handle healthcare products while improving your hospital supply chain operations.

Discover how a sports equipment conveyor system can streamline your athletic gear logistics. Flexible conveyor solutions for all shapes and sizes of sporting goods.