Improving Ergonomics at the Loading Dock with Height-Adjustable Conveyors

Discover how height-adjustable conveyors improve loading dock ergonomics, reduce back injuries, and create safer material handling environments while boosting warehouse productivity.

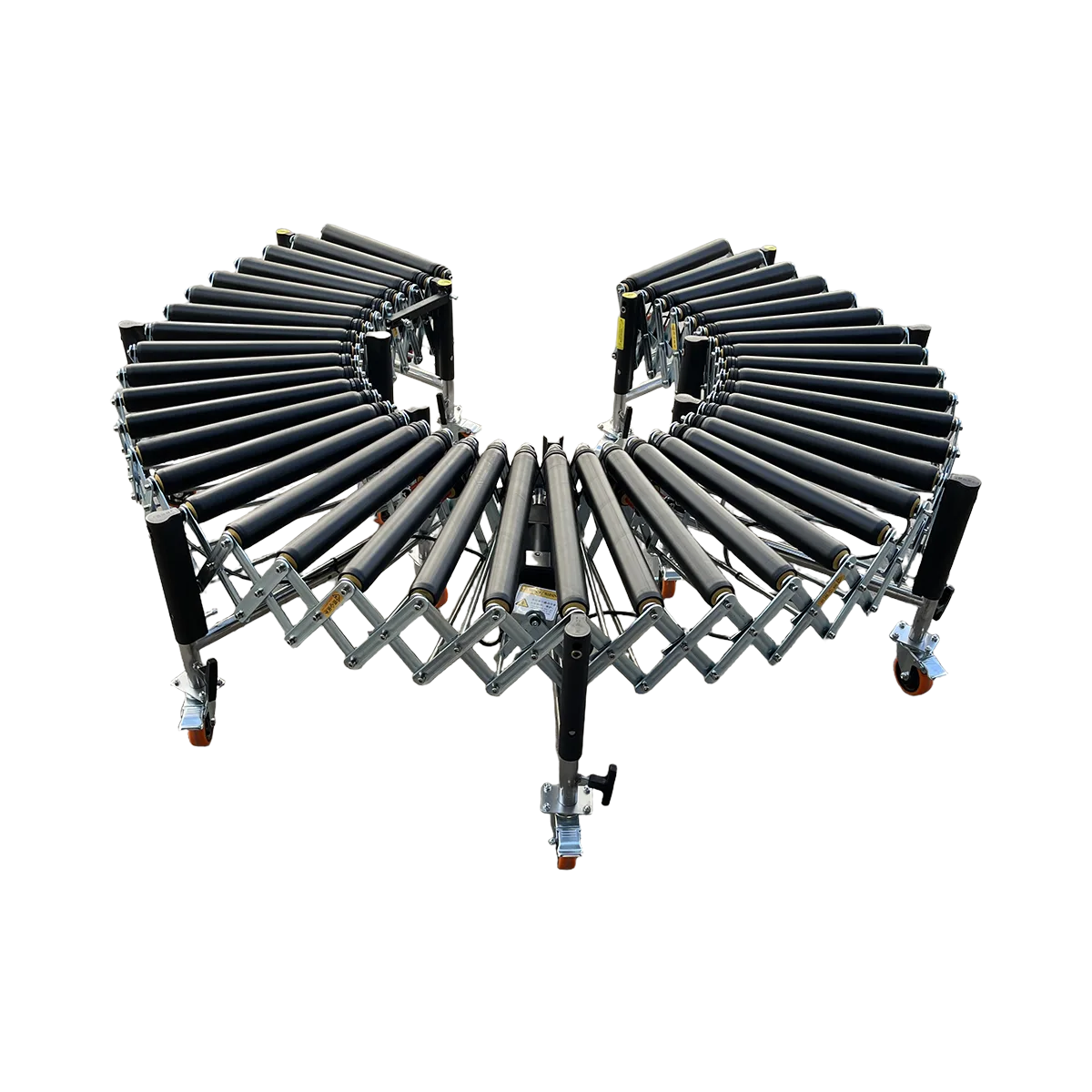

Related Products

-

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

The loading dock represents one of the most physically demanding work environments in any warehouse or distribution center. Workers here face constant risk of musculoskeletal injuries from repetitive lifting, bending, and reaching – activities that can lead to chronic pain, lost productivity, and significant workers’ compensation claims. In this high-risk zone, implementing proper loading dock ergonomics isn’t just good practice; it’s essential for maintaining workforce health and operational efficiency.

The Problem: When Workers Must Adapt to Equipment

Traditional loading and unloading operations often force workers to adapt their bodies to fixed-height equipment, creating numerous ergonomic hazards:

- Constant bending to lift items from low pallets or floor-level conveyors

- Overreaching to access products at the far end of truck beds

- Awkward twisting motions when transferring items between surfaces of different heights

- Repetitive lifting outside the body’s natural power zone

- Excessive physical strain when handling heavy or bulky items at improper heights

These movements place tremendous stress on the back, shoulders, and knees. According to workplace safety statistics, material handling activities account for approximately 32% of all workplace injuries, with back injuries being particularly prevalent and costly.

The Solution: Bringing the Conveyor to the Worker

The fundamental principle of loading dock ergonomics is simple yet powerful: bring the work to the worker, not the worker to the work. Height-adjustable conveyors embody this principle perfectly by:

- Eliminating the need for workers to bend or reach excessively

- Allowing customization of working heights for different individuals

- Adapting to various truck bed heights and loading scenarios

- Creating a seamless transition between different stages of the material handling process

- Maintaining the optimal working height throughout the entire loading/unloading operation

By implementing height-adjustable conveyor systems, warehouses can dramatically reduce the physical strain on workers while simultaneously improving throughput and efficiency.

How Naili’s Systems Improve Ergonomics

Naili offers several conveyor solutions specifically designed to address loading dock ergonomic challenges:

Hydraulic Conveyors: The Ultimate Height-Adjustment Solution

Hydraulic conveyor systems represent the gold standard in ergonomic loading dock equipment. These versatile systems offer:

- Precise height adjustment: Can be positioned exactly at the optimal working height for each employee and task

- Bridge functionality: Creates a smooth transition from ground level to truck bed height (700mm to 2400mm)

- Expandable design: Upper supports can accommodate additional roller conveyors to reach deep into trailers

- Powered operation: Reduces physical effort required to move products

- Adjustable speed controls: Allows customization based on product type and worker comfort

The hydraulic mechanism enables workers to set the exact height needed for each specific loading/unloading task, eliminating awkward postures and reducing fatigue throughout the shift.

Powered Roller Conveyors with Adjustable Legs

Powered roller conveyor systems with height-adjustable legs provide another excellent ergonomic solution:

- Customizable working height: Legs adjust from 450mm to 1500mm depending on model

- Sectional adjustment: Each conveyor section can be set to its own optimal height

- Powered operation: Eliminates the need for manual pushing of heavy items

- Flexible configuration: Can be arranged to create ergonomic workflows

- Mobility: Equipped with locking caster wheels for repositioning as needed

These systems allow warehouse managers to create customized workstations where each section of the conveyor is positioned at the ideal height for the specific task being performed there.

The “Power Zone”: Working Smarter, Not Harder

Ergonomics experts identify the area between a worker’s shoulders and knees as the “power zone” – the region where the body can handle weight most efficiently with minimal strain. Height-adjustable conveyors are designed specifically to keep work within this optimal zone.

When properly positioned:

- Items can be handled with elbows bent at approximately 90 degrees

- The back remains straight rather than bent or twisted

- Shoulders stay relaxed rather than elevated or extended

- Products can be pushed rather than lifted when possible

- Workers maintain a stable base of support with feet firmly planted

By keeping material handling tasks within this power zone, height-adjustable conveyors dramatically reduce the physical stress on workers’ bodies. This not only prevents injuries but also reduces fatigue, allowing workers to maintain productivity throughout their shifts.

The Business Case for Ergonomic Conveyors

Investing in height-adjustable conveyor systems delivers measurable returns across multiple dimensions:

Injury Prevention and Cost Reduction

- Lower workers’ compensation claims

- Reduced absenteeism due to injuries

- Decreased medical costs and insurance premiums

- Fewer replacement worker costs and overtime expenses

Productivity Improvements

- Faster loading/unloading times

- Reduced worker fatigue

- Lower error rates

- More consistent performance throughout shifts

- Higher throughput capacity

Workforce Benefits

- Improved employee satisfaction and retention

- Ability to utilize a more diverse workforce

- Extended working careers for experienced employees

- Reduced training costs due to lower turnover

When analyzing the total cost of ownership:

| Factor | Traditional Fixed-Height Systems | Naili Height-Adjustable Conveyors |

|---|---|---|

| Initial Investment | Lower upfront cost | Moderate investment |

| Injury Costs | High risk of repetitive strain | Significantly reduced injury risk |

| Productivity | Limited by worker fatigue | Maintained throughout shifts |

| Labor Requirements | May require additional workers | Efficient operation with fewer staff |

| Adaptability | Fixed to specific scenarios | Adjustable to various requirements |

| Long-term Value | Higher total cost over time | Better ROI through injury prevention |

For operations handling more than 1000 packages daily, height-adjustable conveyor systems typically deliver ROI within 6-12 months through labor savings, efficiency improvements, and injury prevention.

Implementation Strategies for Maximum Ergonomic Benefit

To maximize the ergonomic benefits of height-adjustable conveyors, consider these implementation strategies:

- Conduct an ergonomic assessment of your current loading dock operations to identify specific pain points and opportunities for improvement

- Train supervisors and workers on proper adjustment and use of height-adjustable equipment

- Create standardized procedures for setting optimal working heights based on:

- Worker height and physical characteristics

- Product weight and dimensions

- Specific task requirements

- Implement job rotation to distribute physical demands across different muscle groups

- Combine height-adjustable conveyors with other ergonomic solutions such as:

- Anti-fatigue matting

- Proper lighting

- Ergonomic handles and grips on packages

- Appropriate personal protective equipment

- Monitor and measure results to quantify improvements in safety metrics, productivity, and worker satisfaction

Conclusion: A Safer, More Productive Loading Dock

The loading dock doesn’t have to be a high-risk zone for worker injuries. By implementing height-adjustable conveyor systems that bring the work to the optimal position for employees, warehouses can create significantly safer and more efficient operations.

A properly designed ergonomic loading dock with height-adjustable conveyors benefits everyone involved: workers experience less physical strain and fewer injuries, operations managers see improved throughput and consistency, and companies enjoy reduced costs and higher productivity.

In today’s competitive logistics environment, where every efficiency matters and skilled workers are increasingly valuable, ergonomic loading dock equipment isn’t just a safety consideration – it’s a strategic business advantage. Naili’s height-adjustable conveyor systems represent a core component of any comprehensive loading dock ergonomics program.

Frequently Asked Questions

What height should a conveyor be for optimal ergonomics?

The ideal conveyor height places the work at approximately elbow height for the operator, typically between 38-45 inches (96-114 cm) from the floor for average-height workers. Height-adjustable conveyors allow customization to each worker’s specific needs.

How much can ergonomic improvements at the loading dock reduce injury rates?

Companies implementing comprehensive ergonomic solutions including height-adjustable equipment typically report 40-70% reductions in musculoskeletal injuries related to material handling activities.

Are height-adjustable conveyors difficult to maintain?

Naili’s height-adjustable conveyors are designed for minimal maintenance. Hydraulic systems require occasional oil checks and leg adjustment mechanisms need basic lubrication, but overall maintenance requirements are significantly lower than the costs associated with workplace injuries.

Can height-adjustable conveyors accommodate workers of different heights?

Yes, this is one of their primary advantages. Unlike fixed-height systems, adjustable conveyors can be quickly modified to suit workers of different statures, making them ideal for facilities with diverse workforces or multiple shifts.

What’s the typical return on investment period for ergonomic conveyor systems?

For operations handling over 1000 packages daily, the ROI period is typically 6-12 months when accounting for all factors including injury prevention, productivity improvements, and reduced labor costs.

Table of Contents

Recent Posts

Discover how to select the perfect conveyor width for your warehouse operations. Our expert guide helps you match box sizes to conveyor dimensions for optimal efficiency and fewer jams.

Discover effective outdoor conveyor solutions for connecting warehouse to truck across open yards. Our guide to all-weather yard logistics will transform your loading efficiency.

Discover the ideal van loading conveyor solution for Sprinter, Transit and other delivery vehicles. Our Micro Hydraulic Conveyor system boosts efficiency while saving labor costs.