Truck Loading Solution Solution

Home > Truck Loading Solution

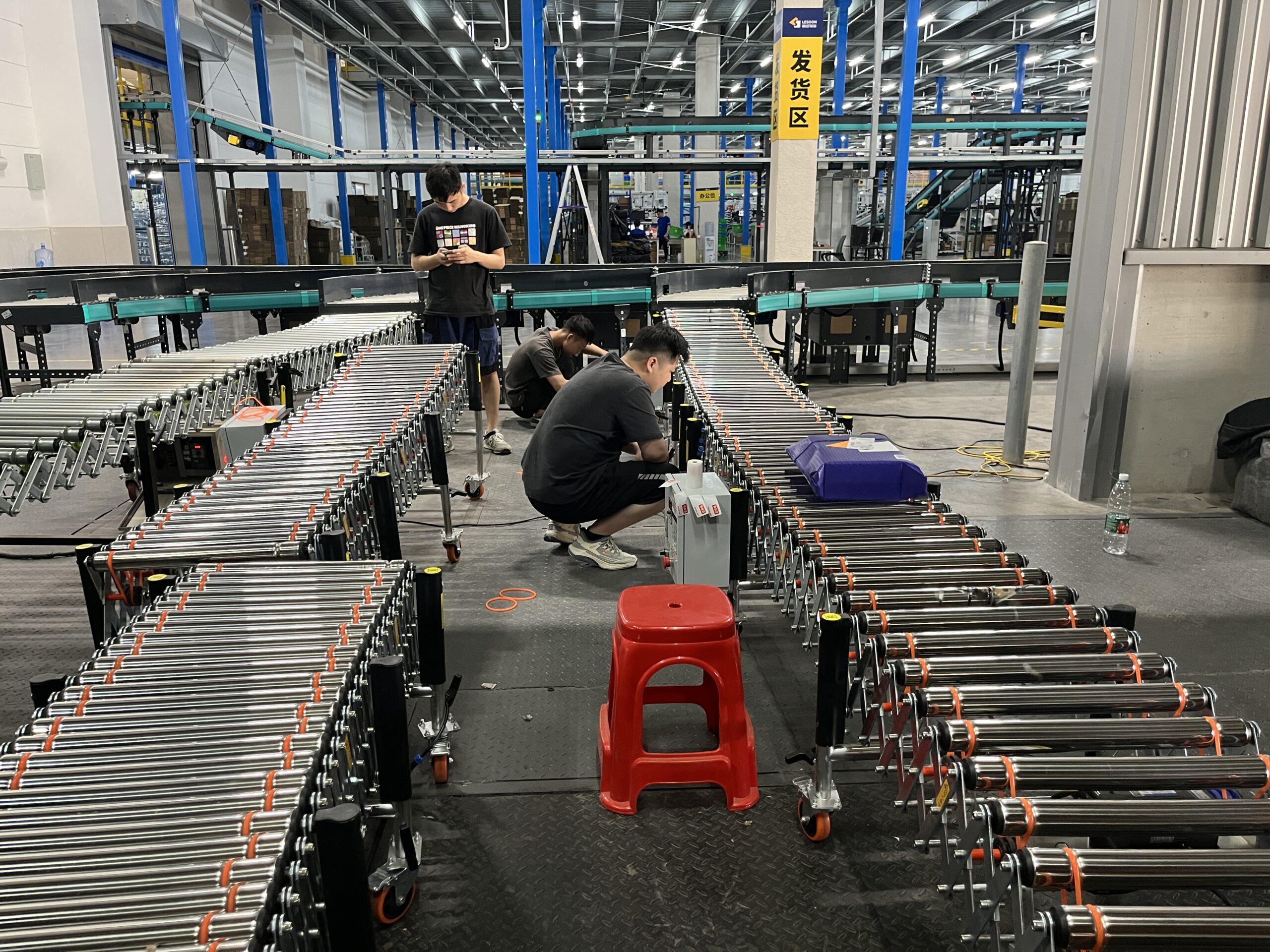

Explore Naili Conveyor’s specialized loading solutions. From telescopic boom conveyors to hydraulic lifts paired with powered rollers, discover how to accelerate truck loading, improve ergonomics, and maximize dock efficiency.

Equipment Used:

Efficiently loading trucks and containers is the final, critical step in your internal logistics chain. At Naili Conveyor, we understand that the right loading solution can dramatically impact your throughput, labor costs, and overall operational agility. This page focuses specifically on how our configurable conveyor systems are engineered to tackle the diverse challenges of loading and unloading operations, ensuring your goods are dispatched swiftly and safely. Whether you’re dealing with high volumes, varied vehicle types, or the need to reach deep into trailers, we offer robust and adaptable loading conveyor systems.

Tailoring the Reach: Getting Goods Deep into the Vehicle

A primary challenge in any loading solution is efficiently placing goods throughout the entire length of a truck or container, especially the far end, without excessive manual effort or in-vehicle maneuvering.

Naili Conveyor offers distinct approaches to master this:

- Direct Reach with Telescopic Boom Conveyors: Our Telescopic Conveyor systems are specifically designed for this. These units extend directly from the dock edge deep into the trailer, creating a continuous moving surface for packages.

- Available in 2, 3, 4, or 5 sections, they can reach impressive lengths (e.g., a 4-section unit can extend up to 17 meters).

- The belt speed is adjustable (typically 10-40 m/min) to match your loading pace.

- They are ideal for facilities with fixed loading docks and a high volume of trailer traffic.

- Important Safety Note: While these can be fitted with manual or electric casters for positioning, multi-section (3+) telescopic conveyors must be ground-locked during operation to prevent tipping due to leverage.

- Elevated Reach with Hydraulic Lifts & Mounted Conveyors: For situations where there’s no fixed dock, or a significant height difference exists between the ground and the truck bed, our Hydraulic Conveyor systems provide the lifting power.

- Models like the Medium Hydraulic Conveyor (7000mm) or Large Hydraulic Conveyor (7900mm) can elevate goods to the necessary height.

- The crucial part of this loading solution is that their upper support frames are designed to carry additional conveyor sections. By mounting several sections of Powered Roller Conveyor (e.g., 5 x 2-meter sections, providing 10 meters of reach) onto the hydraulic lift, you create a powered pathway that extends directly into the truck at the correct height. This is often a more versatile solution than relying on the limited height adjustment of standalone roller conveyor legs to reach into a high truck bed.

- This combination is perfect for ground-level loading operations or yards without built-out docks.

Creating a Continuous Flow: From Warehouse Staging to Truck

An effective loading solution isn’t just about what happens at the truck; it’s about the seamless movement of goods to the truck.

Scenario 1: Feeding a Telescopic Conveyor If you have a Telescopic Conveyor at your dock, a line of Powered Roller Conveyor can act as an efficient feeder system.

- Imagine a 30-meter stretch of powered rollers moving cartons from a packing or staging area directly to the infeed point of the telescopic unit.

- This ensures the telescopic boom is consistently supplied, maximizing its uptime and the overall loading speed.

- The roller conveyor sections can be configured with O-belt drives for general carton handling or multi-wedge belts for heavier, more demanding loads.

Scenario 2: Ground-Level Staging to Hydraulic Lift When using a Hydraulic Conveyor for loading:

- A similar line of Powered Roller Conveyor can transport goods from within the warehouse to the base of the hydraulic lift.

- The goods then transition onto the hydraulic conveyor’s own belt (or a short initial roller section at its base) and are elevated, then moved onto the mounted roller sections extending into the truck.

- This creates an uninterrupted, powered journey for each package.

This continuous flow minimizes manual carrying, reduces staging congestion near the dock, and keeps the loading pace steady. Our roller conveyor sections are modular, allowing you to create transfer lines of almost any required length (e.g., ten 3-meter sections for a 30-meter run).

Handling Diverse Product Types During Loading

Not all goods are created equal, and your loading solution needs to accommodate this. While standard cartons are common, many operations also handle:

- Soft Packages & Bags: For items like polybags, mailer sacks, or bagged agricultural products that might snag or become unstable on standard steel rollers, our Powered Rubber Roller Conveyor is an excellent component to integrate into your loading line, especially for the final sections entering the truck. The rubberized surface provides superior grip and gentle handling.

- Uniform, Flat-Bottomed Items (Gravity Assist): In some parts of the loading process, particularly for shorter transfers from a staging point to the main powered line, or for creating a buffer, sections of Gravity Roller Conveyor or even Gravity Skate Wheel Conveyor can be strategically used. If there’s a slight decline, they offer a zero-energy movement option. Even on a flat surface, goods on our gravity conveyor systems can be easily pushed by operators.

The key is selecting the right conveyor surface and type for each stage of the loading journey, ensuring both efficiency and product integrity.

Key Considerations for Your Naili Loading Solution

When designing your optimal loading solution with Naili Conveyor, keep these points in mind:

- Volume & Speed: How many items per hour/day do you need to load? This influences the choice between manual-assist gravity systems and fully powered lines, as well as the required belt/roller speed (our powered systems typically offer 0-40 m/min). For example, our systems can be configured to handle 2000-2500 medium-to-large cartons per hour.

- Vehicle Types: Are you loading standard trailers, high-cube containers, smaller vans? This dictates the need for hydraulic lifting and the required reach of telescopic or mounted conveyors.

- Dock Configuration: Do you have raised docks, or are you loading from ground level?

- Labor Availability: Our solutions are designed to be efficient, typically requiring 2-3 operators for a complete loading process (e.g., one feeding the warehouse line, one or two in the truck stacking).

- Product Characteristics: Weight, size, packaging type (cartons, bags, totes) will guide the selection of roller type, conveyor width (e.g., 600mm is common for 15kg, 45x35x25cm cartons), and drive mechanism.

Important Integration Note: While Naili systems are modular and designed for compatibility, remember that Telescopic Conveyor units and Hydraulic Conveyor units are not designed to be structurally combined or mounted one onto the other. They serve distinct primary functions but can be linked sequentially using powered roller sections.

Building Your High-Efficiency Loading Dock

Investing in a well-designed loading solution from Naili Conveyor is an investment in speed, safety, and efficiency. Our systems are not complex, automated sorting lines, but rather robust, practical tools focused on the core task of getting goods into vehicles.

- Durability: Expect a service life of 5-10 years with proper maintenance. Our structural components are built to last.

- Ease of Use: Operators typically don’t require extensive specialized training.

- Support: We provide comprehensive installation guidance to help your team get your new loading solution up and running smoothly.

If you’re ready to move beyond manual loading or upgrade an outdated system, explore the possibilities with Naili Conveyor. Contact us today to discuss your specific loading solution requirements, and let our experts help you configure a system that will deliver tangible benefits to your operation.