A Conveyor System for Wholesale Clubs: Moving Bulk Groceries and Merchandise

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Related Products

-

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

Wholesale clubs represent one of the most demanding environments in retail logistics. With massive sales volumes and an inventory consisting primarily of bulk-packaged items, these Costco style warehouse operations present unique material handling challenges. From oversized cereal boxes to multi-packs of canned goods, the sheer weight and volume of merchandise moved daily requires specialized conveyor for bulk goods solutions that can withstand constant heavy use while maintaining operational efficiency. Implementing the right wholesale club logistics system can dramatically reduce labor costs, minimize product damage, and accelerate inventory flow throughout the facility.

The Unique Demands of Wholesale Club Operations

The material handling requirements for wholesale clubs differ significantly from those of traditional retail environments. These differences create specific demands for any conveyor system deployed in these facilities:

Weight Capacity Requirements

Bulk merchandise in wholesale clubs typically weighs substantially more than standard retail packaging:

| Product Category | Typical Retail Weight | Wholesale Club Weight | Increase |

|---|---|---|---|

| Cereal boxes | 0.5 kg | 1.5-2 kg | 300-400% |

| Canned goods | 0.4 kg (single can) | 5-7 kg (multi-pack) | 1200-1700% |

| Beverages | 2 kg (6-pack) | 10-15 kg (24-36 pack) | 500-750% |

| Paper products | 0.5 kg (single roll) | 5-8 kg (bulk pack) | 1000-1600% |

| Rice/grains | 1 kg | 10-25 kg | 1000-2500% |

This dramatic weight difference means standard light-duty conveyor systems simply cannot withstand the daily operational demands of a wholesale environment. When merchandise is moving from receiving areas to sales floors or from picking zones to checkout areas, the conveyor system must handle these heavier loads reliably without premature component failure.

Durability Requirements

Beyond weight capacity, wholesale club conveyor systems must also contend with:

- High throughput volumes – Many wholesale clubs process thousands of cases per hour during peak periods

- Extended operational hours – Often running 16-20 hours daily between restocking and business hours

- Varied package dimensions – From small, dense items to large, bulky packages

- Rough handling – The pace of operations sometimes results in items being dropped or pushed onto conveyors

- Constant use – Unlike seasonal retailers, wholesale clubs maintain consistently high volumes year-round

These factors combine to create an environment where only the most robust case handling system solutions can deliver acceptable service life and reliability.

The Recommended System: Heavy-Duty Roller Conveyors

For wholesale club applications, a network of Naili’s heavy-duty roller conveyor systems provides the optimal combination of durability, capacity, and operational flexibility. The recommended configuration includes:

Powered Sections for Primary Transport

For moving merchandise long distances within the facility, the Powered Roller Conveyor with multi-wedge belt drive (2000mm/section) offers these critical advantages:

- Superior load capacity – Rated for 100 kg/m, easily handling the heaviest bulk merchandise

- Robust construction – 50mm diameter rollers with ≥1.5mm thickness withstand impact from heavy cases

- Adjustable speed – Variable frequency drive allows speeds from 0.3-40 m/min to match workflow requirements

- Modular design – Sections can be combined to create complete transport lines of any length

- Heavy-duty frame – Q345 steel with ≥3.5mm thickness provides exceptional structural integrity

These powered sections should form the backbone of the conveyor network, connecting major operational areas such as receiving, storage, and sales floor staging zones.

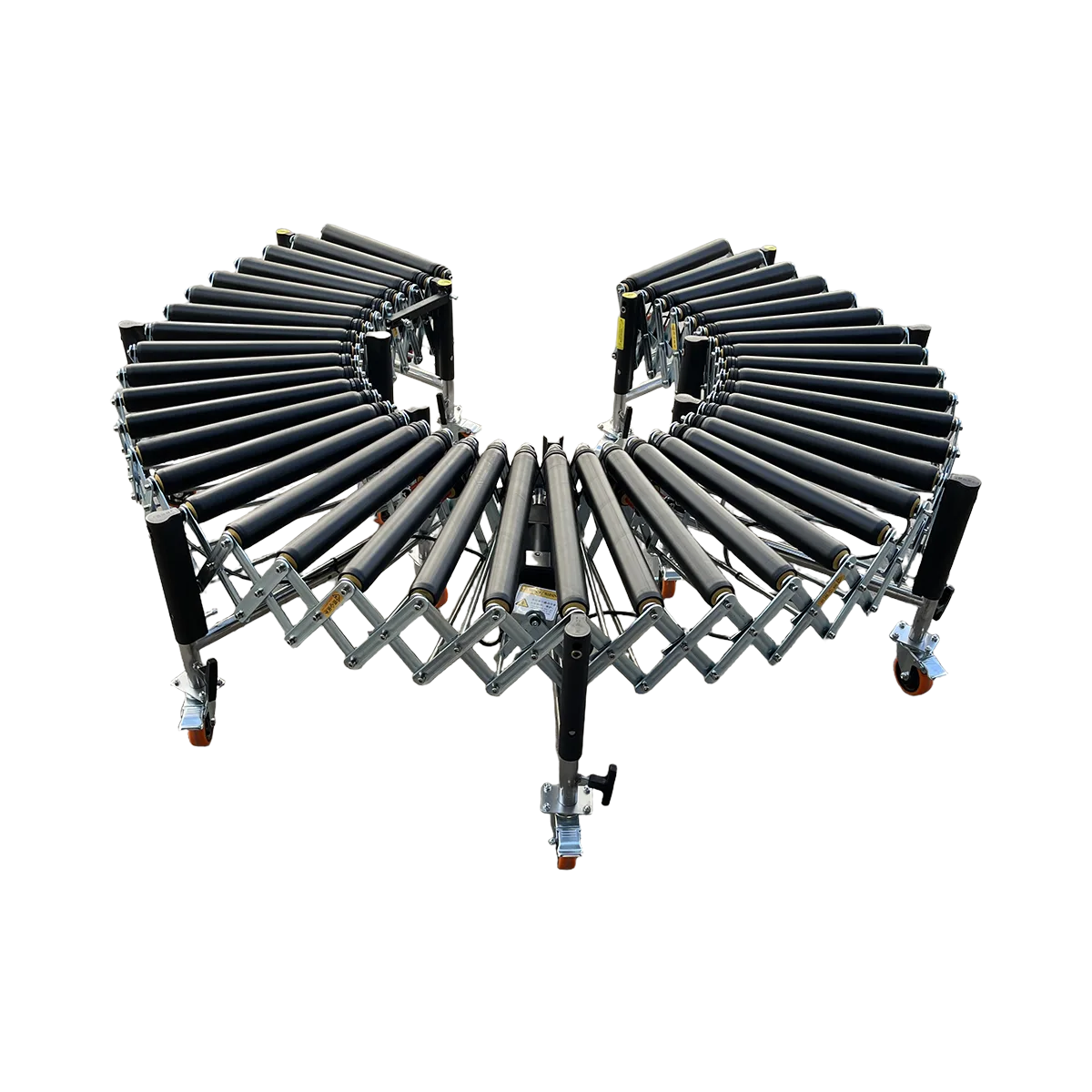

Gravity Sections for Loading/Unloading

At truck docks and workstations, Naili’s Gravity Roller Conveyor (50mm roller diameter) provides an ideal non-powered solution:

- Excellent load rating – 50 kg/m capacity handles typical wholesale club merchandise

- No electrical requirements – Simplifies installation at loading docks and peripheral areas

- Worker-friendly operation – Manual control allows precise positioning of heavy items

- Flexible configuration – Each section extends from 525mm to 1500mm (1:3 ratio)

- Easy maintenance – No motors or drive systems to maintain at high-traffic loading points

These gravity sections work perfectly for manual unloading from trucks and for transitional areas where powered conveyors aren’t necessary or practical.

Implementation Strategy for Wholesale Clubs

A complete conveyor solution for a wholesale club should incorporate both powered and gravity sections in a strategic layout that optimizes operational flow:

Receiving Area Configuration

- Install gravity roller conveyor sections extending from the loading dock into receiving areas

- Position workers at the dock to manually unload trucks onto the gravity sections

- Connect gravity sections to powered roller conveyor lines that transport merchandise to sorting/staging areas

- Implement simple diverters at key junction points to direct specific merchandise categories

Sales Floor Replenishment System

- Position powered roller conveyor along back-of-house corridors connecting storage to sales floor access points

- Install gravity roller sections at transition points where merchandise exits to the sales floor

- Configure adjustable-height supports to accommodate various display heights and staff ergonomics

- Implement stop gates at the end of gravity sections to prevent merchandise from rolling off

Equipment Specifications

For optimal performance in wholesale environments, the following specific equipment is recommended:

- Powered Sections: Multi-wedge belt drive (2000mm/section) with 50mm diameter rollers

- Load capacity: 100 kg/m

- Speed range: 0.3-40 m/min (adjustable)

- Width options: 600mm or 800mm (depending on merchandise size)

- Gravity Sections: 50mm roller diameter (1500mm/section)

- Load capacity: 80 kg/m

- Width options: Match to powered sections for seamless transfers

- Roller spacing: 110mm for stable support of varied package sizes

Maintenance Considerations for High-Volume Operations

The heavy-duty cycle of wholesale club operations requires a proactive maintenance approach to ensure system reliability:

Daily Checks

- Inspect drive belts for proper tension and signs of wear

- Check roller freedom of movement, especially in high-impact loading areas

- Clear any debris from roller surfaces and conveyor frames

- Verify all emergency stops and safety features are functioning properly

Weekly Maintenance

- Lubricate bearings according to manufacturer specifications

- Inspect frame connections and supports for any loosening

- Test variable speed drives through their full range

- Clean photoeyes and sensors if the system includes them

Monthly Procedures

- Perform comprehensive belt inspection and tension adjustment

- Check motor and reducer oil levels

- Inspect electrical connections and control panels

- Evaluate roller wear patterns and rotate or replace as needed

With proper maintenance, a Naili heavy-duty roller conveyor system can provide 5-10 years of reliable service even in the demanding wholesale club environment.

Return on Investment Analysis

The implementation of a properly designed conveyor system in a wholesale club environment typically delivers ROI through several key mechanisms:

- Labor reduction – Automated horizontal transport reduces the need for manual handling, often cutting labor requirements by 20-30%

- Injury prevention – Reducing manual lifting of heavy bulk items significantly decreases workplace injuries and associated costs

- Product damage reduction – Consistent, controlled movement minimizes drops and impacts that lead to damaged merchandise

- Throughput increases – Facilities typically report 25-40% higher processing capacity with well-designed conveyor systems

- Space utilization – Conveyors can utilize overhead space, freeing valuable floor area for merchandise or operations

For most wholesale club operations, these combined benefits typically deliver complete return on investment within 12-18 months of implementation.

Conclusion: Engineered for Wholesale Demands

Wholesale clubs require material handling systems that can match their unique operational scale and intensity. The combination of Naili’s powered and gravity roller conveyors creates a robust, no-frills solution perfectly adapted to the demands of moving bulk merchandise through high-volume facilities.

By focusing on high weight capacity (80-100 kg/m), durable construction, and system flexibility, this conveyor network provides the reliability needed for the constant heavy-duty cycle of wholesale club logistics. The strategic placement of powered sections for long-distance transfers and gravity sections for manual handling areas creates an efficient, ergonomic system that supports both operational efficiency and worker safety.

For wholesale club operators looking to optimize their material handling capabilities, this heavy-duty roller conveyor solution delivers the perfect balance of performance, durability, and value.

Frequently Asked Questions

What makes wholesale club conveyor requirements different from standard retail?

Wholesale clubs handle merchandise that is significantly heavier and bulkier than traditional retail, with typical items weighing 3-10 times more than their standard retail counterparts. This requires conveyors with higher load ratings, more robust construction, and greater durability.

How does a wholesale club conveyor system improve efficiency?

A properly designed system reduces manual handling of heavy items, creates more efficient workflow paths, minimizes product damage, and allows for faster processing of merchandise from receiving to sales floor placement, typically improving overall throughput by 25-40%.

What is the typical lifespan of a conveyor system in a wholesale club environment?

With proper maintenance, Naili’s heavy-duty roller conveyors can provide 5-10 years of reliable service even under the demanding conditions of wholesale club operations. The most critical maintenance factor is regular inspection and replacement of drive belts.

Can existing conveyor systems be expanded as wholesale club operations grow?

Yes, both the powered and gravity roller conveyor sections are designed with modularity in mind. Additional sections can be added to extend lines, and new lines can be integrated with existing systems as operational needs evolve.

What safety features should be incorporated into wholesale club conveyor systems?

Key safety features include emergency stop controls at regular intervals, pinch point guards at transitions between conveyor sections, clearly marked crossing points where workers need to move across conveyor lines, and proper training for all staff who work with or around the conveyor system.

Table of Contents

Recent Posts

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.

Discover how mobile powered roller conveyors transform cross-docking efficiency, creating adaptable “land bridges” that accelerate freight movement between loading docks while minimizing manual handling and labor costs.

Streamline your pet food warehouse operations with specialized conveyor systems for heavy bags. Our hydraulic and rubber roller conveyor combo maximizes efficiency and safety.

Discover how a high-capacity conveyor for tiles can transform your flooring warehouse logistics with efficient solutions for handling these exceptionally dense materials.