A Warehouse Conveyor Solution for Wine and Spirits Distribution

Discover the optimal wine case conveyor system that protects your valuable inventory while improving spirits distribution logistics efficiency and safety.

Related Products

-

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

In the specialized world of wine and spirits distribution, moving cases of bottled products presents a unique set of challenges that standard material handling equipment often fails to address. The dual nature of these products—simultaneously heavy and fragile—requires thoughtful solutions that protect both inventory and workers. A purpose-built wine case conveyor system can transform these challenges into a streamlined, efficient process while significantly reducing the risk of costly breakage. This article explores how the right conveyor for fragile goods can revolutionize spirits distribution logistics.

The Unique Challenges of Wine and Spirits Distribution

Wine and spirits products present distinctive handling challenges that set them apart from other warehouse goods:

- Concentrated Weight: A standard case of 12 wine bottles typically weighs 16-20kg, while spirit cases can exceed 20kg

- Fragility: Glass bottles are vulnerable to breakage from impacts, vibration, and sudden movements

- High Value: With individual bottles often valued at $20-$200+, breakage represents a significant financial loss

- Variable Packaging: From traditional cardboard cases to wooden crates for premium products

- Slippery Surfaces: Smooth cardboard case exteriors can easily slide on standard metal rollers

- Moisture Concerns: Wine cellars and storage areas often maintain higher humidity levels

- Temperature Sensitivity: Many products require climate-controlled environments

The combination of weight and fragility makes manual handling particularly problematic. Each time a worker lifts a case, there’s risk of both personal injury and product damage. In high-volume operations handling hundreds or thousands of cases daily, even a small percentage of breakage can translate to substantial financial losses.

The Risks of Manual Handling

Traditional manual handling of wine and spirits cases introduces multiple risk factors:

Product Damage Risks

- Dropped Cases: Even from a small height, a dropped case can result in multiple broken bottles

- Collision Damage: Cases impacting shelving, doorways, or other obstacles during transport

- Stacking Issues: Improper stacking on pallets can crush lower boxes or create unstable loads

- Vibration Damage: Excessive shaking during transport can affect product quality, especially for aged wines

- Label Damage: Rough handling can damage labels, reducing product value and marketability

Worker Safety Concerns

- Back Injuries: The awkward size and weight of wine cases makes proper lifting technique difficult

- Repetitive Strain: High-volume operations can lead to cumulative trauma disorders

- Slip Hazards: Broken bottles create dangerous walking conditions

- Fatigue-Related Accidents: As workers tire during shifts, accident risk increases

- Cuts and Lacerations: From broken glass when breakage occurs

These risks compound in larger operations where speed requirements often conflict with careful handling needs. Without proper equipment, distributors face the difficult choice between operational efficiency and product protection.

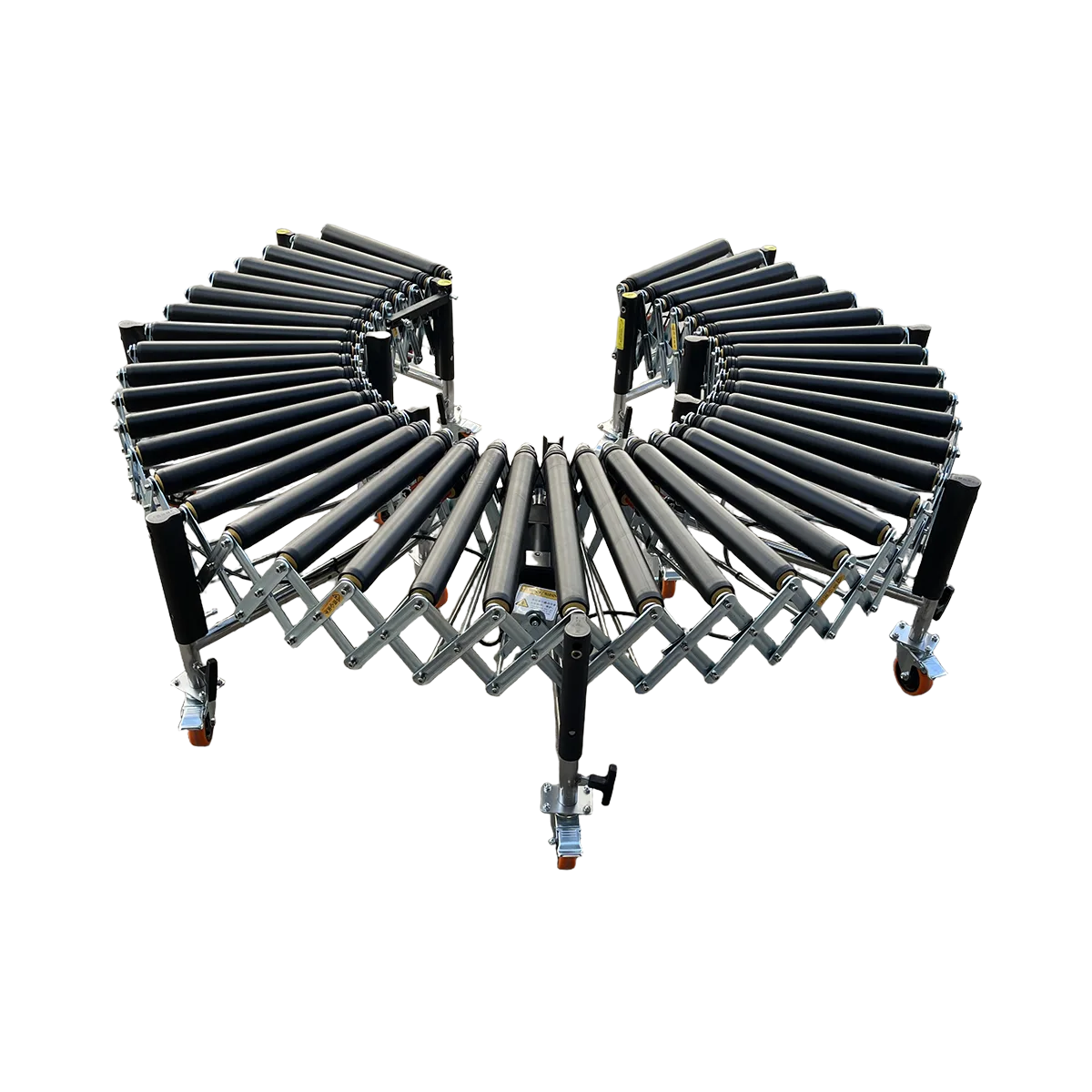

The Ideal Conveyor: Powered Rubber Roller Conveyor

For wine and spirits distribution, the powered rubber roller conveyor offers an ideal solution that addresses the unique challenges of handling bottled goods:

Superior Grip for Secure Transport

The most critical advantage of rubber-coated rollers is their exceptional grip on smooth cardboard surfaces:

- High-Friction Surface: PVC-coated rollers provide significantly more friction than metal alternatives

- Slip Prevention: Cases remain stationary when the conveyor stops, preventing unexpected movements

- Controlled Movement: Even on slight inclines, cases won’t slide unintentionally

- Consistent Spacing: Maintains proper distance between cases, preventing collisions

- Edge Protection: Rubber coating helps prevent carton edges from catching on roller joints

This enhanced grip is particularly valuable for wine cases with glossy finishes or shrink-wrapped exteriors that tend to slide on standard metal rollers, especially in humid storage environments.

Gentle Handling for Fragile Contents

Beyond grip, the powered rubber roller conveyor offers sophisticated control features that protect fragile contents:

- Variable Speed Control: Adjust conveyor speed from 0.3-40 m/min to find the optimal pace for different products

- Smooth Starts/Stops: Gradual acceleration and deceleration prevent sudden jolts that can damage bottles

- Vibration Reduction: Rubber coating absorbs vibrations that could otherwise affect wine quality

- Consistent Power: The multi-wedge belt drive system provides smooth, constant torque across the entire conveyor

- Bidirectional Capability: Allows precise positioning and direction changes without manual handling

These features create a handling environment that’s significantly gentler than manual transport, reducing breakage while maintaining efficient throughput.

Robust Construction for Heavy Loads

Despite their fragility, wine and spirits cases are deceptively heavy, requiring a conveyor with substantial load capacity:

- High Weight Capacity: Supports up to 120 kg/m, easily handling the concentrated weight of multiple cases

- Sturdy Frame Construction: 3.5mm Q345 steel framework prevents flexing under load

- 54mm Diameter Rollers: Larger than standard rollers (typically 50mm) for improved durability

- 57mm Roller Spacing: Provides continuous support for even the smallest cases

- Adjustable Height: Support legs adjust from 450-1500mm to match various loading scenarios

- Locking Casters: 4-inch heavy-duty casters with full braking capability ensure stability during operation

This robust construction ensures the conveyor maintains structural integrity even under the constant weight of fully loaded wine cases, providing years of reliable service.

Practical Application in Wine and Spirits Distribution

The powered rubber roller conveyor creates an efficient workflow for receiving, moving, and shipping bottled products:

Streamlined Receiving Process

For incoming shipments, the conveyor system transforms the unloading process:

- Pallet Breakdown: Workers remove cases from pallets at the receiving area

- Conveyor Loading: Cases are placed on the conveyor with minimal lifting

- Inspection Point: Products move past quality control checkpoints at a controlled pace

- Sorting Decision: Cases are directed to appropriate storage areas based on product type

- Storage Transfer: Products arrive at their destination with minimal handling

This workflow significantly reduces the manual carrying distance and the number of times each case is physically handled, decreasing both breakage risk and worker fatigue.

Efficient Internal Transfers

For moving inventory within the facility, the conveyor system offers multiple advantages:

- Direct Routes: Create straight-line paths between storage and processing areas

- Reduced Aisle Congestion: Minimizes forklift and hand truck traffic in busy areas

- Continuous Flow: Maintains steady product movement without stops and starts

- Minimized Lifting: Workers place and remove cases at ergonomic heights

- Speed Matching: Variable speed control allows synchronization with other warehouse processes

By establishing dedicated product movement channels, the powered rubber roller conveyor helps organize workflow and improve overall warehouse efficiency.

Optimized Truck Loading Operations

When preparing outbound shipments, the conveyor system creates an organized loading process:

- Order Assembly: Cases are gathered from storage and placed on the conveyor

- Verification Point: Products pass final check stations at controlled speed

- Direct Truck Loading: Conveyor extends to the truck bed for direct transfer

- Minimal Handling: Cases move from storage to truck with as few as two touch points

- Consistent Pacing: Maintains steady loading rhythm for maximum efficiency

This streamlined approach allows workers to focus on proper placement and securing of loads rather than the physical exertion of carrying heavy cases, resulting in better-organized shipments with less damage.

Key Benefits for Wine and Spirits Distributors

Implementing a powered rubber roller conveyor system delivers multiple measurable benefits:

Dramatic Reduction in Breakage

- 75-90% Decrease: Typical reduction in handling-related breakage compared to manual methods

- Elimination of Drop Damage: Removes the primary cause of catastrophic multi-bottle breakage

- Consistent Handling: Standardizes the movement process, removing individual handling variations

- Gentle Transitions: Smooth transfers between conveyor sections protect delicate contents

- Vibration Control: Minimizes the micro-impacts that can affect wine quality and bottle integrity

For a mid-sized distributor handling 10,000 cases monthly with an average value of $150 per case, reducing breakage by just 1% can save $15,000 monthly in direct product costs, not including the associated cleanup and administrative costs.

Improved Worker Safety and Satisfaction

- Reduced Lifting Injuries: Minimizes the need for manual lifting of heavy cases

- Decreased Fatigue: Workers expend less physical energy throughout their shifts

- Safer Environment: Less broken glass and fewer spills mean reduced slip hazards

- Improved Morale: Employees appreciate equipment that makes their jobs easier and safer

- Lower Turnover: Better working conditions lead to improved staff retention

These improvements translate directly to reduced workers’ compensation claims, decreased absenteeism, and lower training costs associated with employee turnover.

Enhanced Operational Efficiency

- Increased Throughput: Process 2,000-2,500 cases per hour compared to 800-1,000 with manual methods

- Labor Optimization: Redeploy staff from carrying boxes to higher-value activities

- Consistent Pace: Establishes a steady workflow rhythm that improves overall productivity

- Space Utilization: Creates organized product flow paths that maximize available space

- Reduced Congestion: Decreases traffic in aisles and work areas

These efficiency gains allow distributors to handle growing volume without proportional increases in labor costs, creating scalability that supports business growth.

Implementation Considerations

When integrating a powered rubber roller conveyor into a wine and spirits distribution operation, several factors should be considered:

Layout Planning

- Flow Analysis: Map current product movement patterns before designing conveyor layout

- Bottleneck Identification: Target areas where manual handling currently creates delays

- Height Transitions: Plan for any elevation changes between receiving, storage, and shipping

- Temperature Zones: Consider transitions between ambient and climate-controlled areas

- Future Expansion: Allow space for additional conveyor sections as volume grows

A thoughtfully designed layout maximizes the return on investment by addressing the most problematic handling points first.

System Configuration

- Width Selection: Choose appropriate width (500/600/800mm) based on case dimensions

- Speed Settings: Determine optimal conveyor speed for different product types

- Control Placement: Position control panels at convenient operator locations

- Power Requirements: Ensure adequate electrical service for the entire system

- Connectivity: Plan how the conveyor will interface with existing equipment

These configuration decisions should be based on actual product dimensions and handling requirements rather than general guidelines.

Training and Adoption

- Operator Training: Ensure staff understands proper loading techniques and speed control

- Maintenance Procedures: Establish regular inspection and maintenance protocols

- Usage Guidelines: Develop clear procedures for different product types

- Performance Metrics: Set targets for throughput and reduction in breakage

- Feedback Loop: Create mechanisms for staff to suggest improvements

Proper training and clear procedures are essential for maximizing the benefits of the new equipment.

Return on Investment Analysis

For wine and spirits distributors, the investment in a powered rubber roller conveyor typically delivers rapid returns:

- Breakage Reduction: 75-90% decrease in handling-related product damage

- Labor Efficiency: 30-40% reduction in labor hours for the same throughput

- Injury Prevention: 50-60% fewer handling-related injuries and associated costs

- Space Utilization: 20-25% more efficient use of warehouse floor space

- Energy Efficiency: Lower physical exertion translates to reduced HVAC demands

Most wine and spirits operations handling 5,000+ cases monthly can achieve full return on investment within 12-18 months through these combined savings, with the breakage reduction component often covering equipment costs within the first year alone.

Conclusion: Protecting Your Valuable Inventory

In the wine and spirits distribution industry, where products are simultaneously heavy, fragile, and valuable, investing in the right handling equipment is not merely an operational decision but a critical protection strategy. The powered rubber roller conveyor, with its grip-enhancing rubber rollers and precise speed control, represents an ideal solution that addresses the unique challenges of this specialized industry.

By implementing this purpose-built conveyor for fragile goods, distributors can dramatically reduce breakage, improve worker safety, and enhance operational efficiency. The result is a more profitable operation where valuable products move safely from receiving to shipping with minimal risk and maximum control.

Frequently Asked Questions

What makes wine and spirits cases particularly challenging to handle compared to other warehouse products?

Wine and spirits cases combine substantial weight (16-20kg for a standard case) with extreme fragility. The smooth cardboard exteriors tend to slip on standard metal rollers, while the glass contents can break from even minor impacts. Additionally, the high value of the products makes any breakage particularly costly compared to most warehouse goods.

How does the rubber coating on the rollers benefit wine case handling specifically?

The PVC rubber coating provides significantly more friction than metal rollers, preventing the smooth cardboard wine cases from sliding unexpectedly. This is especially important for maintaining proper spacing between cases, preventing collisions, and ensuring cases don’t slide on inclines. The rubber also absorbs vibration, reducing the micro-impacts that can affect wine quality over time.

What throughput can be expected when using a powered rubber roller conveyor for wine distribution?

A properly implemented system typically handles 2,000-2,500 cases per hour, depending on case size and weight. This represents a 150-200% improvement over manual methods that typically process 800-1,000 cases per hour. The consistent pace also reduces bottlenecks and allows for more predictable workflow planning.

What maintenance is required for a powered rubber roller conveyor in a wine warehouse environment?

Regular maintenance includes monthly drive belt tension checks, quarterly bearing lubrication, and weekly cleaning of roller surfaces to remove dust and any spilled product. The rubber rollers should be inspected monthly for signs of wear or damage. In climate-controlled wine environments, the lower temperature and higher humidity may require slight adjustments to lubrication schedules.

How does the variable speed control benefit handling different types of wine and spirits products?

Variable speed control (0.3-40 m/min) allows operators to adjust conveyor speed based on product characteristics. Heavier cases of spirits might require slower speeds for stability, while standard wine cases can move more quickly. Premium products or wooden crates might warrant the slowest settings to ensure absolutely minimal vibration and maximum care.

Table of Contents

Recent Posts

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.

Discover how mobile powered roller conveyors transform cross-docking efficiency, creating adaptable “land bridges” that accelerate freight movement between loading docks while minimizing manual handling and labor costs.

Streamline your pet food warehouse operations with specialized conveyor systems for heavy bags. Our hydraulic and rubber roller conveyor combo maximizes efficiency and safety.

Discover how a high-capacity conveyor for tiles can transform your flooring warehouse logistics with efficient solutions for handling these exceptionally dense materials.