Accelerating Cross-Docking Operations with Mobile Powered Conveyors

Discover how mobile powered roller conveyors transform cross-docking efficiency, creating adaptable “land bridges” that accelerate freight movement between loading docks while minimizing manual handling and labor costs.

Related Products

-

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

In today’s fast-paced logistics environment, the essence of cross-docking is speed — receiving goods and immediately transferring them to outbound transportation with minimal storage time. This streamlined approach eliminates wasteful warehousing steps, reduces handling costs, and accelerates delivery timelines. However, many facilities still face a critical bottleneck: the physical transfer of freight between inbound and outbound docks.

When shipments arrive at your cross-dock facility, time becomes your most valuable currency. Every minute spent manually moving products from the unloading bay of Truck A to the loading bay of Truck B directly impacts your bottom line through increased labor costs, extended dock occupancy times, and delayed shipments.

The Cross-Docking Bottleneck

Traditional cross-docking operations often rely on manual methods to bridge the gap between unloading and loading zones:

- Workers manually carrying boxes across the dock floor

- Staff pushing hand trucks loaded with merchandise between bays

- Forklifts shuttling pallets in repetitive trips across the facility

These approaches create several significant challenges:

- Labor intensity: Requires multiple workers dedicated to transport tasks

- Safety concerns: Increases risk of injuries from lifting, carrying, and potential collisions

- Speed limitations: Creates a throughput ceiling based on human capacity

- Space inefficiency: Moving equipment and personnel require wide transit lanes

- Scheduling complexity: Coordinating the physical movement between multiple dock doors

As cross-docking volumes increase, these manual methods become increasingly unsustainable, creating workflow bottlenecks that undermine the very speed advantages cross-docking should deliver.

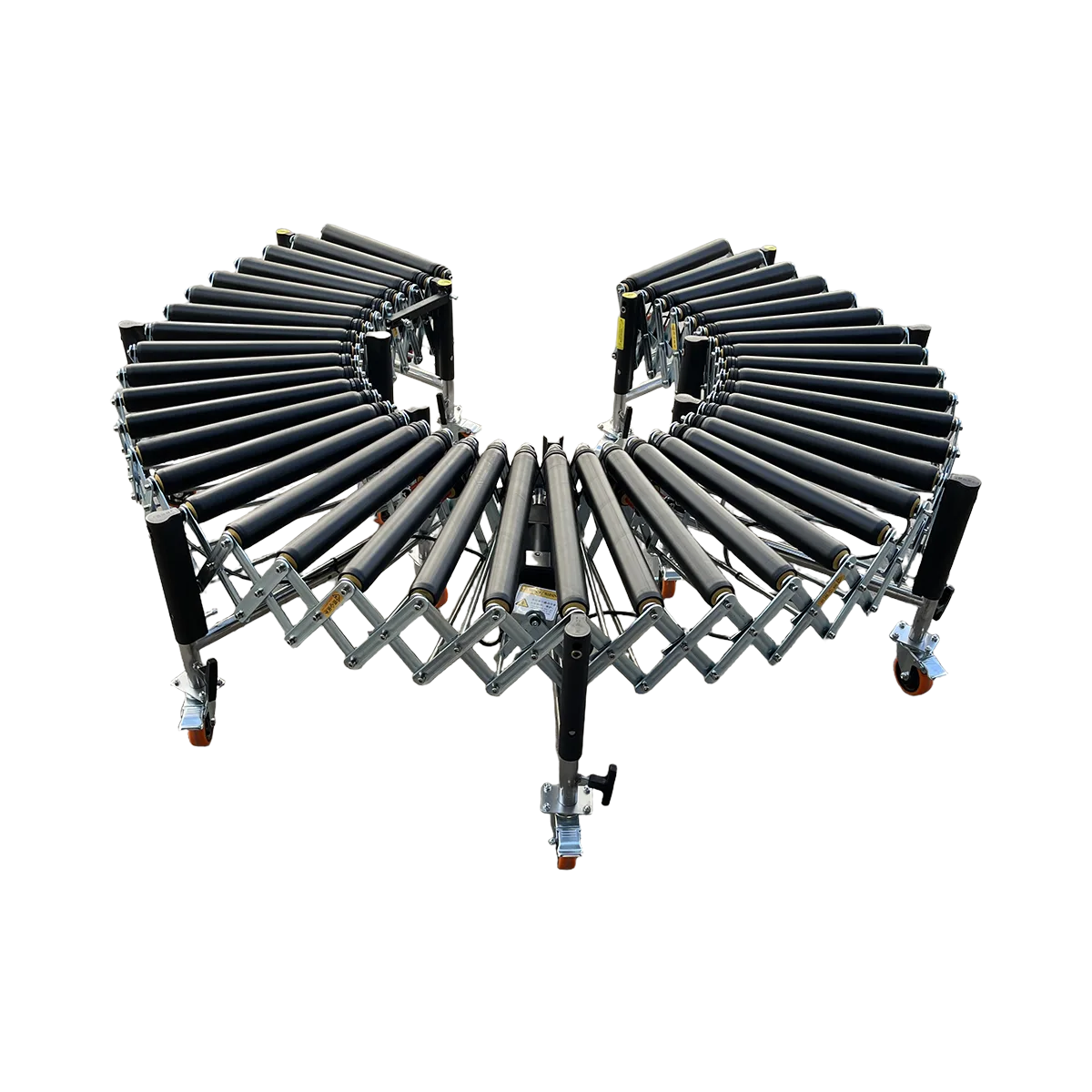

The Solution: Mobile Powered Roller Conveyors

The most effective solution to cross-docking bottlenecks is creating a direct “land bridge” between inbound and outbound trucks using Naili’s mobile, extendable powered roller conveyor systems. These flexible, powered transportation lines create an immediate connection that eliminates the need for manual carrying or pushing freight across your dock floor.

How the Mobile Conveyor Bridge Works

By linking several sections of powered roller conveyor together, you create a continuous powered line spanning the width of your cross-docking facility. This configuration offers numerous advantages:

- Direct transfer: Goods move seamlessly from the unloading point to the loading point without intermediate handling

- Continuous flow: Once placed on the conveyor, items move automatically to their destination

- Labor reduction: Minimizes the number of workers needed for transport tasks

- Increased throughput: Handles higher volumes than manual methods could achieve

- Space optimization: Creates an efficient transit lane that maximizes dock space utilization

The key to this solution’s effectiveness lies in the unique design of Naili’s powered roller conveyor systems, which combine mobility, flexibility, and reliable performance.

Key Features of Naili’s Mobile Powered Conveyors

Naili’s powered roller conveyors are specifically engineered for cross-docking applications with features that address the unique challenges of freight transfer:

1. Mobility and Flexibility

- Extendable design: Conveyors can stretch from compact storage position to full operational length

- Wheeled base: Each section includes heavy-duty casters for quick repositioning

- Height adjustability: Support legs can be adjusted to match various truck and dock heights

- Quick coupling: Sections connect rapidly with hook and bolt interfacing

2. Robust Performance

- Powerful motors: Drive systems capable of moving up to 100 kg per meter

- Adjustable speed: Variable frequency controls allow speed adjustment from 0.3-40 m/min

- Bi-directional capability: Can run forward or reverse for maximum operational flexibility

- Continuous duty operation: Designed for high-volume, multi-shift environments

3. Practical Design Features

- Multiple width options: Available in 500mm, 600mm, and 800mm widths to accommodate various package sizes

- Durable construction: Made with high-quality steel and components for long service life

- Simple controls: Intuitive control panels with forward/reverse, emergency stop, and speed controls

- Low maintenance requirements: Designed for minimal downtime and easy servicing

The Cross-Docking Workflow with Powered Conveyors

When implementing a mobile powered conveyor solution, your cross-docking workflow becomes significantly more efficient:

1. Receiving Process

As goods are unloaded from the inbound truck, workers place them directly onto the start of the powered conveyor line. The automated system immediately begins transporting items across the dock, eliminating wait times and reducing manual handling.

2. Transport Phase

Products move automatically along the powered conveyor “land bridge,” traveling at a controlled, consistent speed. The roller design accommodates various package sizes and weights, maintaining smooth flow throughout the transfer process.

3. Loading Process

At the outbound truck, workers remove items from the conveyor end and load them directly into the vehicle. This streamlined process eliminates intermediate handling steps and reduces the physical strain on workers.

4. System Adaptability

When dock assignments change, the entire conveyor line can be quickly reconfigured. Sections can be added, removed, or repositioned to create new transfer paths between different dock doors, adapting to daily operational changes in minutes rather than hours.

The Mobility Advantage

The most significant benefit of Naili’s mobile powered conveyor solution is its adaptability to changing cross-dock requirements. Unlike fixed conveyor systems that lock you into a predetermined layout, these mobile units offer:

- Quick reconfiguration: Entire lines can be set up, modified, or removed in minutes

- Dock door flexibility: Easily reposition to service different dock doors as schedules change

- Seasonal scalability: Add or remove sections to match volume fluctuations

- Storage efficiency: Compact to a fraction of their operational length when not needed

- Facility adaptation: Work around existing equipment and infrastructure

This mobility advantage is particularly valuable in cross-docking operations where inbound and outbound door assignments frequently change based on carrier schedules, volume fluctuations, and priority shipments.

Real-World Performance Benefits

Implementing Naili’s mobile powered conveyor solution delivers measurable improvements to cross-docking operations:

1. Increased Throughput

- Reduces package transfer time by up to 60% compared to manual methods

- Enables processing of more shipments per shift with the same workforce

- Handles higher package volumes during peak periods without proportional labor increases

2. Labor Optimization

- Reduces the number of workers needed for transfer tasks by up to 50%

- Minimizes physical strain, reducing fatigue and increasing productivity

- Allows reassignment of staff to higher-value tasks like quality checking and inventory management

3. Space Utilization

- Maximizes productive use of limited dock floor space

- Requires less clearance than forklift or pallet jack operations

- Creates more efficient traffic patterns for workers and equipment

4. Cost Reduction

- Lowers labor costs through improved efficiency and reduced headcount requirements

- Decreases injury-related expenses by minimizing manual handling

- Extends dock door utilization by processing more shipments per door per day

Application Scenarios

Naili’s mobile powered roller conveyor systems excel in various cross-docking scenarios:

Parcel and Small Package Operations

For parcel carriers and e-commerce fulfillment operations handling thousands of smaller packages daily, powered conveyors create high-speed transfer lines between sorting areas and outbound delivery vehicles. The system’s ability to handle diverse package sizes makes it ideal for mixed shipments.

Retail Distribution

Retail chains using cross-docking to transfer merchandise from suppliers to stores benefit from powered conveyors that can handle both case goods and individual items. The system maintains product organization during transfer, simplifying the final loading process.

Food and Beverage Distribution

Time-sensitive food products require quick handling to maintain freshness and reduce temperature exposure. Powered conveyors accelerate the transfer process, moving refrigerated or frozen items between temperature-controlled trailers with minimal exposure time.

Manufacturing Supply Chains

Just-in-time manufacturing operations use cross-docking to transfer components directly from suppliers to production lines. Mobile powered conveyors create flexible connections that can adapt to changing production schedules and varying component sizes.

Implementation Considerations

When implementing a mobile powered conveyor solution for your cross-docking operation, consider these key factors:

1. Facility Assessment

- Measure the typical distance between inbound and outbound doors

- Identify potential obstructions or traffic patterns to consider

- Determine power availability throughout the dock area

- Assess floor conditions for smooth conveyor movement

2. Conveyor Configuration

- Select appropriate conveyor widths based on typical package sizes

- Determine the optimal number of sections needed to span your facility

- Choose between O-ring or multi-wedge belt drive systems based on load requirements

- Consider adding curves or diverters for more complex flow patterns

3. Training and Adoption

- Provide operator training on proper conveyor setup and operation

- Establish clear procedures for reconfiguring the system as needs change

- Develop maintenance routines to ensure reliable performance

- Create contingency plans for peak volume periods

4. Integration with Existing Systems

- Consider how the conveyor system will interface with other material handling equipment

- Evaluate opportunities to integrate with WMS or dock management systems

- Plan for future expansion or additional automation possibilities

Conclusion: Eliminating Wasteful Transit Time

Cross-docking’s primary purpose is eliminating wasteful steps in the supply chain. By implementing Naili’s mobile powered roller conveyor solution, you remove the final significant bottleneck in this streamlined process: the physical transfer of goods across your dock floor.

This innovative approach creates a direct, powered connection between inbound and outbound shipments, transforming your cross-dock facility into a high-speed transfer point that truly delivers on the promise of minimal handling and maximum throughput. The result is faster shipment processing, lower labor costs, and improved competitive advantage in today’s speed-driven logistics landscape.

By eliminating wasteful transit time and manual labor in your cross-docking operations, you can focus on what matters most: getting products to their destinations faster, more efficiently, and at lower cost than ever before.

Frequently Asked Questions

What types of products can be transported on powered roller conveyors?

Naili’s powered roller conveyors can handle a wide range of products, including boxes, totes, cases, and other items with stable bottoms. They’re designed for packages ranging from small parcels up to items weighing 80-100kg per meter of conveyor, making them suitable for most cross-docking applications.

How quickly can a mobile conveyor system be reconfigured?

A trained team can reconfigure a mobile powered conveyor line in as little as 5-10 minutes. The quick-connect coupling system and wheeled bases allow sections to be easily repositioned, and height adjustments can be made rapidly to accommodate different dock and truck heights.

What is the ROI timeframe for implementing powered conveyors in cross-docking?

Most operations see a return on investment within 6-12 months, primarily through labor savings, increased throughput capacity, and reduced dock occupancy times. The exact payback period depends on your specific operation’s volume, labor costs, and current efficiency levels.

Can powered roller conveyors be integrated with other material handling systems?

Yes, Naili’s powered roller conveyors are designed to interface seamlessly with other material handling equipment. They can connect to fixed conveyor systems, hydraulic conveyor systems, sorting devices, and other warehouse automation solutions to create a comprehensive material flow solution.

What maintenance is required for mobile powered conveyors?

Maintenance requirements are minimal, focusing on regular inspection of drive belts, rollers, and electrical components. The O-ring or multi-wedge drive belts typically need replacement every 6-12 months depending on usage, while the frame and structural components are built for years of reliable service.

Table of Contents

Recent Posts

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.

Streamline your pet food warehouse operations with specialized conveyor systems for heavy bags. Our hydraulic and rubber roller conveyor combo maximizes efficiency and safety.

Discover how a high-capacity conveyor for tiles can transform your flooring warehouse logistics with efficient solutions for handling these exceptionally dense materials.