How to Safely Manage Fireworks Logistics with a Gravity Conveyor System

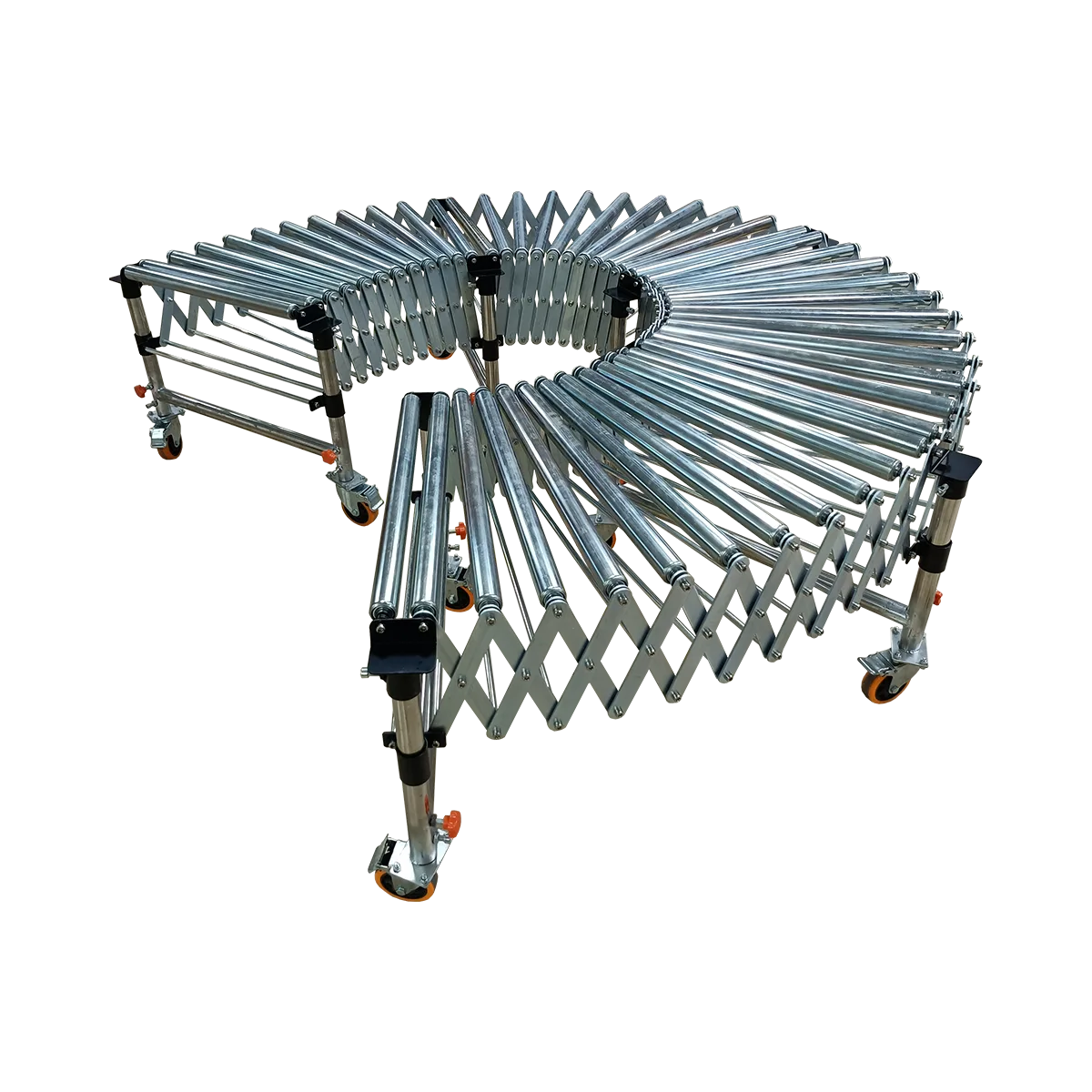

Discover how to implement a safe fireworks loading conveyor system using non-powered gravity roller conveyors. Minimize spark risks while efficiently handling hazardous materials.

Related Products

-

Gravity Roller Conveyor – Roller Diameter 50 mm – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Gravity Roller Conveyor – Roller Diameter 38 mm – 1700 mm/SectionCollapsed Length

485 mm

Extended Length1700 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

The transportation and handling of pyrotechnics present unique challenges that combine standard logistics concerns with critical safety requirements. When managing fireworks loading conveyor systems, minimizing potential ignition sources becomes paramount. Traditional powered conveyor systems, with their motors, electrical components, and potential for generating sparks, introduce unnecessary risks in environments where explosive materials are present. This is where non-powered warehouse solutions offer a compelling alternative for explosives logistics.

The Challenge: Safety First in Fireworks Handling

Fireworks distribution centers face a dual challenge: they must efficiently move products through their facilities while maintaining stringent safety protocols. The fundamental concern is clear – any system used for handling hazardous materials like fireworks must minimize ignition risks while still providing practical material handling capabilities.

Traditional material handling solutions present several challenges when working with pyrotechnics:

| Method | Limitations with Fireworks |

|---|---|

| Powered conveyors | Electrical components create ignition risks |

| Forklifts | Internal combustion engines and battery systems pose hazards |

| Manual carrying | Inefficient, physically demanding, and increases drop risks |

| Vertical lifts | Complex mechanisms with multiple potential failure points |

The ideal solution must eliminate electrical components near handling areas, provide smooth and controlled movement, be easily grounded to prevent static buildup, and maintain operational efficiency despite these safety constraints.

The Solution: Gravity Roller Conveyor Systems for Fireworks

A gravity roller conveyor setup provides the perfect balance of safety and functionality for fireworks handling operations. By relying solely on gravity and manual force rather than motors or electrical systems, these conveyors eliminate significant ignition risks at the source.

Why Gravity Systems Excel for Pyrotechnic Handling

Naili’s Gravity Roller Conveyor systems offer several critical safety advantages for fireworks logistics:

- Zero Electrical Components: With no motors, control systems, or wiring, the system eliminates electrical ignition risks entirely

- Static Dissipation: All-steel construction is easily grounded, preventing static electricity buildup

- Controlled Movement: Adjustable slopes allow for precise control of product flow rates

- No Sparking Parts: No friction between metal components that could generate sparks

- Simple Design: Fewer moving parts means fewer potential failure points

- Robust Construction: Durable steel rollers can handle the weight of fireworks cases without deformation

The system’s fundamental safety features align perfectly with the hazardous materials handling requirements of the fireworks industry.

Technical Specifications for Fireworks Applications

For optimal performance when handling fireworks cases, the Gravity Roller Conveyor with 50mm roller diameter (1500mm/section) is recommended for its superior load capacity of 50 kg/m, which comfortably accommodates standard fireworks packaging.

Key specifications that make this model ideal for pyrotechnic handling include:

- Heavy-duty rollers: 50mm diameter with ≥1.5mm thickness, zinc-plated or 201 stainless steel

- Robust frame: Q345 steel with ≥3.5mm thickness for structural integrity

- Adjustable height: Multiple leg length options (450-680/550-820/750-1200/900-1500 mm)

- Flexible configuration: Each section extends from 525mm to 1500mm (1:3 ratio)

- Roller spacing: 110mm spacing allows smooth movement of various box sizes

- Locking casters: Provides stability during operation while maintaining mobility when needed

These specifications ensure that the conveyor system can safely handle the weight and dimensions of standard fireworks cases while providing the necessary stability for safe operation.

Setting Up a Safe Fireworks Handling System

Creating an effective fireworks loading conveyor system using gravity conveyors requires careful planning and proper implementation. Here’s how to establish a safe and efficient setup:

For Unloading Operations

- Position the gravity conveyor at a gentle decline from the truck bed to the warehouse floor

- Adjust leg heights to create a consistent 2-3 degree slope

- Lock all casters once the system is properly positioned

- Verify stability by testing with empty boxes before handling actual fireworks

- Establish clear staging areas at both ends of the conveyor line

- Assign dedicated personnel for loading and unloading the conveyor

For Horizontal Transfer Operations

- Set up multiple sections of gravity conveyors in a horizontal configuration

- Adjust all legs to maintain a consistent height throughout the line

- Create designated push zones where workers can safely propel items along the line

- Implement stop blocks at the end of lines to prevent overruns

- Ensure adequate spacing between parallel lines for worker movement

Safety Protocols for Gravity Conveyor Operation

When implementing a gravity roller conveyor setup for fireworks, standard operating procedures should include:

- Regular static discharge: Workers should ground themselves before handling products

- Product spacing: Maintain minimum distances between cases on the conveyor

- Speed control: Implement simple brake rollers at strategic points if needed

- Inspection schedule: Regularly check all components for damage or wear

- Housekeeping: Keep conveyor surfaces and surrounding areas clean and free of debris

- Emergency procedures: Clear protocols for handling incidents, including evacuation routes

- No-spark tools: Use only approved non-sparking tools for any adjustments or maintenance

- Weather considerations: Take additional precautions during dry, static-prone conditions

These procedures complement the inherent safety features of the gravity conveyor system to create a comprehensive safety approach.

Case Study: Implementing Gravity Systems in Fireworks Distribution

A medium-sized fireworks distributor in the Midwest replaced their partially mechanized system with Naili’s Gravity Roller Conveyors after a risk assessment identified electrical components as a significant hazard. The new system consisted of:

- A primary receiving line with a gentle slope from truck height to warehouse level

- Four horizontal sorting lines leading to different storage areas

- A shipping line configured to load outbound trucks

The results included:

- Complete elimination of electrical ignition sources in the handling area

- 15% increase in throughput due to improved workflow design

- Zero safety incidents in the two years following implementation

- Significant reduction in insurance premiums due to lower risk profile

- Additional flexibility to reconfigure lines as needed for seasonal variations

This real-world application demonstrates how non-powered warehouse solutions can actually improve both safety and efficiency in hazardous materials handling.

Additional Safety Considerations

While the gravity conveyor system itself minimizes many risks, comprehensive safety in fireworks handling requires attention to the entire environment:

- Building grounding: Ensure the entire facility has proper electrical grounding

- Temperature and humidity control: Maintain appropriate environmental conditions

- Separation of processes: Keep packaging and administrative areas separate from handling zones

- Personal protective equipment: Provide appropriate PPE for all workers

- Training programs: Implement regular safety training specific to pyrotechnic handling

- Signage and procedures: Clear visual indicators of hazard zones and handling requirements

- Limited access: Restrict entry to handling areas to essential personnel only

These measures work in conjunction with the non-powered conveyor system to create multiple layers of safety protection.

Conclusion: Simple Solutions for Specialized Safety

The use of Naili’s Gravity Roller Conveyors for fireworks logistics represents a perfect alignment of safety requirements and practical functionality. By eliminating electrical components and potential ignition sources from the immediate loading area, these systems provide inherent safety advantages that power-driven alternatives simply cannot match.

The robust, all-steel construction offers the durability needed for commercial operations while being easily grounded to prevent static electricity buildup. The simplicity of the design means fewer potential failure points, further enhancing safety in environments where failure consequences could be severe.

For fireworks distributors, display companies, and retailers handling pyrotechnic products, a properly implemented gravity roller conveyor setup isn’t merely a material handling solution—it’s a critical component of a comprehensive safety system that protects products, facilities, and most importantly, people.

By choosing non-powered gravity systems for fireworks logistics, companies demonstrate their commitment to safety while still maintaining the efficiency necessary for commercial operations. It’s a simple, smart, and safe material handling solution perfectly adapted to the unique demands of the fireworks industry.

Frequently Asked Questions

What makes gravity conveyors safer than powered systems for fireworks handling?

Gravity conveyors eliminate electrical components and motors that could create sparks or heat sources, significantly reducing ignition risks in environments where explosive materials are present.

Can gravity conveyors handle the weight of commercial fireworks cases?

Yes, Naili’s 50mm Gravity Roller Conveyor has a load capacity of 50kg/m, which is more than sufficient for standard commercial fireworks packaging that typically weighs between 10-25kg per case.

How do workers control the speed of boxes on a gravity conveyor?

Speed is primarily controlled through proper slope design, typically 2-5 degrees. For additional control, brake rollers can be installed at strategic points, or workers can use manual pressure to regulate movement.

What maintenance is required for gravity conveyor systems in fireworks facilities?

Maintenance is minimal but should include regular inspection of rollers for free movement, checking frame and leg connections for tightness, cleaning roller surfaces, and verifying that all grounding connections are intact.

Are there specific regulations for conveyor systems in fireworks handling facilities?

Regulations vary by location, but facilities handling fireworks typically must comply with local fire codes, ATF regulations (in the US), and industry-specific guidelines that often specify non-sparking equipment requirements for material handling systems.

Table of Contents

Recent Posts

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.

Discover how mobile powered roller conveyors transform cross-docking efficiency, creating adaptable “land bridges” that accelerate freight movement between loading docks while minimizing manual handling and labor costs.

Streamline your pet food warehouse operations with specialized conveyor systems for heavy bags. Our hydraulic and rubber roller conveyor combo maximizes efficiency and safety.

Discover how a high-capacity conveyor for tiles can transform your flooring warehouse logistics with efficient solutions for handling these exceptionally dense materials.