Loading and Unloading Automotive Tires: A Specialized Conveyor Approach

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.

Related Products

-

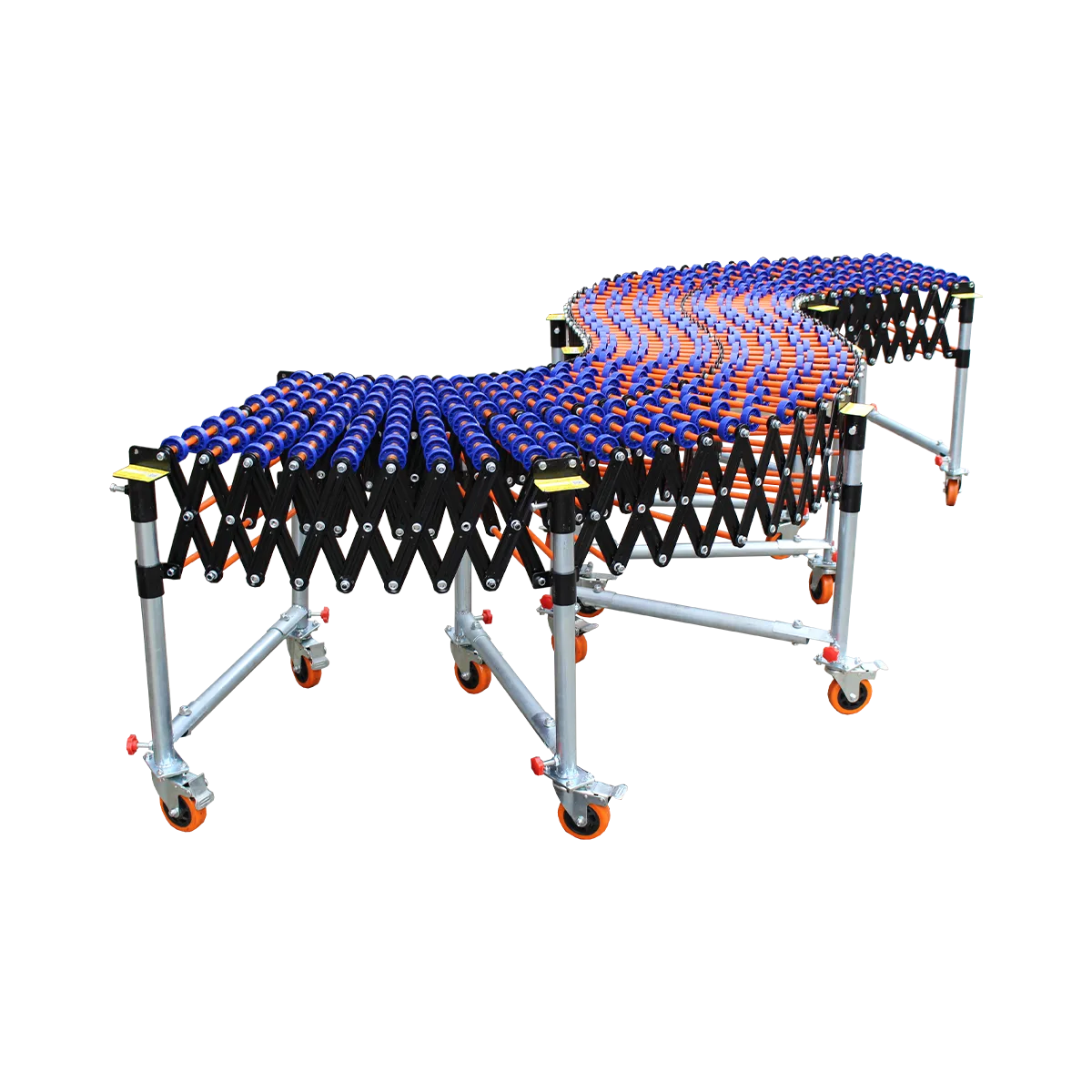

Gravity Skate Wheel Conveyor – 2100 mm/SectionCollapsed Length

420 mm

Extended Length2100 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

-

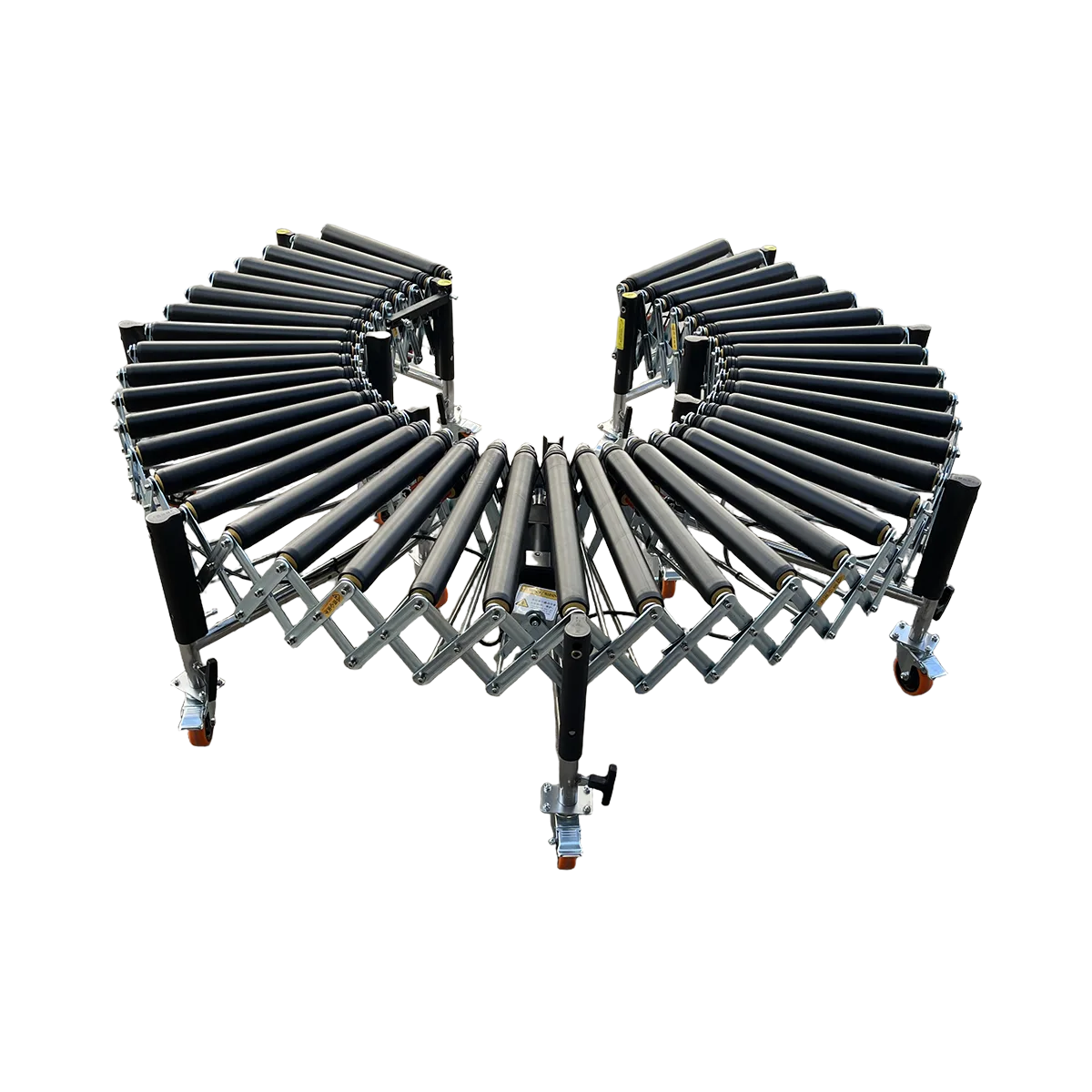

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

Automotive tires present unique handling challenges in logistics and distribution environments. These round, bulky items are notoriously awkward to manage – they roll unpredictably when placed on standard surfaces, can be surprisingly heavy (typically 15-25kg each), and their smooth rubber surfaces make them prone to sliding. Traditional manual handling methods not only slow down operations but also pose significant ergonomic risks to workers who must repeatedly lift, carry, and position these unwieldy items throughout the day.

For tire manufacturers, distributors, automotive plants, and service centers, finding an efficient solution for moving tires from delivery vehicles to storage or assembly areas is crucial for operational efficiency. The right conveyor for tires can dramatically streamline these processes, reduce labor costs, and minimize the risk of workplace injuries.

Why Traditional Conveyors Fall Short for Tire Handling

Not all conveyor systems are created equal when it comes to handling automotive tires. Standard conveyor designs that work well for boxes and regular-shaped items often struggle with the unique properties of tires:

Issues with Skate Wheel Conveyors

Gravity skate wheel conveyor systems, while effective for many applications, present several challenges when handling tires:

- Insufficient support: The narrow contact points between the tire and skate wheels create instability

- Unpredictable movement: Tires can roll or shift unexpectedly due to their round shape

- Poor tracking: Maintaining straight-line movement is difficult as tires tend to veer off course

- Potential damage: The concentrated pressure points can potentially deform tires over time

Limitations of Standard Metal Roller Conveyors

Standard roller conveyor systems with metal rollers also have significant drawbacks:

- Inadequate grip: Metal surfaces provide minimal friction against rubber tires

- Drift problems: Tires easily slide sideways rather than moving straight along the conveyor

- Difficult inclines: Handling elevation changes is nearly impossible as tires slip backward

- Speed control issues: Controlling the movement of tires, especially on declines, becomes challenging

These limitations often result in inefficient operations, requiring constant manual intervention to keep tires properly positioned on the conveyor line. The result is reduced throughput, increased labor requirements, and potential damage to valuable inventory.

The Naili Tire Handling Solution: Powered Rubber Roller Conveyor

Addressing the unique challenges of tire handling requires specialized equipment designed with the specific properties of tires in mind. The powered rubber roller conveyor from Naili Conveyor offers a purpose-built solution that transforms tire logistics operations.

Key Features for Superior Tire Handling

The design of Naili’s Powered Rubber Roller Conveyor incorporates several critical features that make it ideal for tire handling:

Rubber-Coated Rollers for Enhanced Grip

The most distinctive feature of this tire handling system is its polyvinyl chloride (PVC) rubber-coated rollers. This coating creates several significant advantages:

- Superior traction: The rubber surface grips the tire’s exterior, preventing unwanted rolling or sliding

- Straight-line movement: Tires maintain their path along the conveyor without veering off course

- Enhanced stability: The increased friction keeps tires properly positioned during transport

- Gentle handling: The rubber coating provides cushioning that protects tire integrity

Powered, Continuous Motion

Unlike gravity-dependent systems, the powered design ensures reliable movement regardless of incline:

- Controlled speed: Adjustable conveyor speed up to 40 m/min provides consistent tire movement

- Reliable operation: Motor-driven rollers ensure tires move at a steady pace without manual assistance

- Bi-directional capability: Forward and reverse functionality for flexible workflow configuration

- Incline performance: Successfully moves tires up slopes that would be impossible with non-powered systems

Heavy-Duty Construction for Durability

Tire handling requires robust equipment that can withstand continuous use:

- High load capacity: Supports up to 120 kg per meter, easily handling even the heaviest truck tires

- Industrial-grade materials: Construction using Q345 steel frame and 201 stainless steel components

- Reinforced structure: Designed to handle the concentrated weight of multiple tires

- Long service life: Built to last 5-10 years under normal operating conditions

Optimal Configuration for Automotive Tire Operations

For tire-specific applications, Naili recommends the following configuration of the Powered Rubber Roller Conveyor:

Width Selection

The 800mm wide version is specifically recommended for automotive tire handling operations. This width provides several advantages:

- Accommodates all standard tire sizes: From compact car tires to light truck tires

- Prevents jamming: Provides sufficient clearance to handle tires without side contact

- Stability: Offers adequate support surface to keep tires properly positioned

- Future-proofing: Handles the trend toward larger tire sizes in modern vehicles

Section Length and Layout Considerations

For efficient tire handling operations, consider these layout guidelines:

- Standard section length: Each section extends from 560mm (compressed) to 1100mm (expanded)

- Modular design: Multiple sections can be connected to create custom-length conveyor lines

- Flexible configuration: Can be arranged in straight lines or with turns to navigate facility layout

- Expandability: System can grow with changing operational needs

Height Adjustment for Ergonomic Operation

The adjustable height feature is particularly valuable for tire handling operations:

- Multiple height options: Available in 450-680mm, 550-820mm, 750-1200mm, or 900-1500mm ranges

- Ergonomic loading/unloading: Can be set at optimal height to reduce worker strain

- Dock-to-storage flexibility: Adjusts to match loading dock height or internal facility requirements

- Vehicle compatibility: Can be positioned at the right height for various truck beds and trailers

Application Scenarios for Tire Handling

The powered rubber roller conveyor solution proves invaluable across various tire handling operations:

Tire Distribution Centers

In dedicated tire distribution facilities, the conveyor system transforms operations by:

- Creating efficient unloading paths from delivery trucks directly to storage areas

- Establishing organized sorting lanes for different tire types and sizes

- Providing reliable movement between different sections of the warehouse

- Enabling faster order fulfillment by moving tires efficiently from storage to shipping

Automotive Manufacturing Plants

Vehicle manufacturing facilities benefit from improved tire logistics:

- Streamlining the movement of tires from receiving to assembly areas

- Creating buffer zones where tires can stage before being moved to installation points

- Reducing the manual handling required to position tires for mounting on vehicles

- Improving overall assembly line efficiency through better component flow

Tire Retail and Service Centers

For businesses selling and servicing tires, the system offers:

- Efficient transfer of new inventory from delivery vehicles to storage racks

- Organized movement of tires from storage to service bays

- Improved customer service through faster access to inventory

- Reduced worker fatigue by eliminating manual carrying of heavy tires

Fleet Maintenance Facilities

Operations servicing multiple vehicles benefit from:

- Streamlined seasonal tire changeover processes for entire fleets

- Efficient movement of tires between storage and service areas

- Improved inventory management through organized tire flow

- Reduced labor costs associated with tire handling

Implementation and Operational Considerations

Successfully implementing a tire handling conveyor system requires attention to several key factors:

Space Planning and Layout

- Workflow analysis: Carefully map the movement of tires through your facility

- Bottleneck identification: Target the areas where manual handling currently slows operations

- Traffic patterns: Ensure the conveyor placement doesn’t interfere with other facility activities

- Expansion planning: Allow space for potential future extension of the conveyor system

Power and Installation Requirements

- Electrical supply: System requires 380V or 220V power source

- Floor conditions: Ensure level, solid flooring at installation location

- Assembly: While professional installation is not required, Naili provides detailed guidance

- Testing: Conduct thorough testing with actual tire inventory before full implementation

Operational Best Practices

- Worker positioning: Place staff strategically at loading and unloading points

- Speed adjustment: Set optimal conveyor speed based on tire size and operator capabilities

- Regular maintenance: Establish routine inspection of rollers, drive belts, and electrical components

- Staff training: Ensure all operators understand proper loading techniques and safety procedures

Measuring ROI: The Business Case for Specialized Tire Handling

Investing in a specialized conveyor for tires delivers measurable returns through several key improvements:

Labor Efficiency

- Reduces the number of workers required for tire movement operations

- Minimizes ergonomic injuries and associated costs

- Decreases fatigue, maintaining productivity throughout shifts

- Allows reallocation of staff to higher-value activities

Throughput Improvement

- Increases the number of tires that can be processed per hour

- Reduces truck unloading and loading times

- Minimizes bottlenecks in tire movement workflows

- Enables faster response to customer or production needs

Space Utilization

- Creates more organized tire flow, reducing staging area requirements

- Minimizes congestion in work areas

- Allows for more efficient storage configurations

- Provides flexibility to adapt to changing facility needs

Equipment Longevity

- Purpose-built design lasts longer than improvised solutions

- Reduces wear and damage to other material handling equipment

- Decreases maintenance needs compared to non-specialized alternatives

- Provides reliable performance over 5-10 year service life

Conclusion: Taming Tire Logistics with Specialized Conveyor Solutions

The unique challenges of handling automotive tires demand specialized solutions. The powered rubber roller conveyor system from Naili represents a purpose-built approach that addresses these challenges directly, providing superior grip and controlled movement for even the most unwieldy tires.

By implementing this specialized tire handling system, operations can dramatically improve efficiency, reduce manual handling requirements, and create a safer work environment. The result is a streamlined tire logistics operation that supports faster processing, lower labor costs, and improved customer service.

For any facility dealing with the daily challenges of moving automotive tires – whether a distribution center, manufacturing plant, or service operation – investing in the right conveyor technology transforms what was once a logistical headache into a smooth, efficient process. With Naili’s Powered Rubber Roller Conveyor, you can finally tame your tire logistics with maximum grip and control.

Frequently Asked Questions

What makes rubber roller conveyors better than standard conveyors for tire handling?

The rubber coating on the rollers provides superior grip on the tire’s surface, preventing unwanted rolling or sliding. This keeps tires moving straight along the conveyor and prevents the drift problems common with metal rollers or skate wheel systems.

What is the maximum tire size this conveyor can handle?

The 800mm wide Powered Rubber Roller Conveyor can accommodate virtually all passenger vehicle, SUV, and light truck tires. For specialized applications involving larger commercial or agricultural tires, custom width options may be available upon consultation.

Can the conveyor handle different tire types simultaneously?

Yes, the conveyor can handle mixed tire types and sizes simultaneously without adjustment. The rubber-coated rollers provide consistent grip regardless of tire diameter or tread pattern, making it ideal for operations that process various tire types.

Is it possible to create turns or curves in the conveyor layout?

Yes, the modular design allows for flexible configurations including turns. Multiple conveyor sections can be arranged at angles to create custom layouts that navigate around obstacles or fit specific facility constraints.

What maintenance is required for the rubber roller conveyor?

Regular maintenance includes monthly inspection of drive belts, quarterly lubrication of bearings, and periodic cleaning of the rubber rollers to maintain optimal grip. The rubber coating is designed for durability, but should be inspected for wear, particularly in high-volume operations.

Table of Contents

Recent Posts

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Discover how mobile powered roller conveyors transform cross-docking efficiency, creating adaptable “land bridges” that accelerate freight movement between loading docks while minimizing manual handling and labor costs.

Streamline your pet food warehouse operations with specialized conveyor systems for heavy bags. Our hydraulic and rubber roller conveyor combo maximizes efficiency and safety.

Discover how a high-capacity conveyor for tiles can transform your flooring warehouse logistics with efficient solutions for handling these exceptionally dense materials.