The Best Way to Move Boxed Flowers and Live Plants in a Nursery or DC

Discover the ideal nursery conveyor system that provides gentle transportation for delicate plants while maximizing efficiency in your horticultural logistics operations.

Related Products

-

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

In the specialized world of horticulture logistics, moving live plants and floral arrangements presents unique challenges that standard material handling equipment struggles to address. The delicate nature of these products requires a nursery conveyor system that prioritizes gentle handling while maintaining the speed necessary to preserve freshness. Implementing the right solution for handling live plants can transform your operation, reducing damage rates while improving efficiency. This article explores how specialized conveyor systems can provide the perfect balance of care and productivity in moving these fragile botanical products.

The Unique Challenges of Horticultural Material Handling

Moving live plants and floral products involves several distinctive challenges that set them apart from other warehouse goods:

Fragility Concerns

Unlike standard warehouse products, living plants and fresh flowers are exceptionally vulnerable to damage:

- Stem Breakage: Even minor impacts can snap delicate stems and branches

- Soil Displacement: Sudden movements can dislodge growing media, exposing or damaging roots

- Flower Damage: Blooms can be crushed, bruised, or dislodged during transport

- Leaf Marking: Pressure or abrasion can cause visible damage to foliage

- Container Tipping: Unstable movement can cause pots to tip, spilling soil and damaging plants

These vulnerabilities make the transportation method critically important in maintaining product quality and value.

Varied Product Dimensions

Horticultural products rarely conform to standard shipping dimensions:

- Inconsistent Heights: Plants range from short groundcovers to tall saplings

- Irregular Shapes: Natural growth patterns create asymmetrical dimensions

- Mixed Load Requirements: Operations often need to move different plant types simultaneously

- Seasonal Variation: Product mix changes throughout the growing season

- Special Packaging: Some plants require specialized protective packaging that creates handling challenges

This dimensional variation makes it difficult to standardize handling procedures without the right equipment.

Time Sensitivity

Living products deteriorate quickly when subjected to suboptimal conditions:

- Temperature Exposure: Extended time in non-climate-controlled areas accelerates decline

- Moisture Management: Water needs continue during the transportation process

- Light Requirements: Extended periods in low light can stress plants

- Airflow Needs: Proper ventilation prevents fungal issues during transit

- Processing Speed: Quick movement from growing areas to shipping points maximizes shelf life

Every minute saved in the transportation process directly contributes to product longevity and quality upon arrival at the destination.

Why Standard Conveyors Fall Short

Conventional material handling equipment typically fails to address the specific needs of horticultural products:

- Excessive Vibration: Standard conveyors often create vibrations that damage delicate plant tissues

- Abrupt Starts/Stops: Sudden movements cause soil shifting and plant stress

- Inadequate Support: Insufficient roller coverage allows small containers to tip or fall

- Speed Control Issues: Fixed-speed systems move too quickly for fragile items

- Inflexible Routes: Many systems can’t adapt to seasonal workflow changes common in horticulture

These limitations often lead nurseries and plant distributors to rely on manual handling, sacrificing efficiency and increasing labor costs while still risking product damage.

The Ideal Solution: O-Belt Driven Powered Roller Conveyor

For horticultural operations, the powered roller conveyor with O-belt drive technology represents an ideal solution that addresses the unique challenges of moving living products:

Gentle Drive System for Delicate Products

The O-belt drive mechanism provides several key advantages for handling live plants:

- Smooth Acceleration: Gradual starts prevent sudden movements that could tip containers

- Low Vibration Operation: O-belt system transmits minimal vibration to transported items

- Quiet Running: Reduced noise creates a less stressful environment for workers and plants

- Soft Stops: Gentle deceleration prevents momentum-related damage

- Even Power Distribution: Consistent drive force across all rollers ensures smooth product flow

This gentle handling approach significantly reduces mechanical stress on plants during transport, preserving quality from greenhouse to loading dock.

Precise Speed Control for Optimal Handling

The variable speed control feature is particularly valuable for plant handling:

- Speed Range: Adjustable from 0.3-40 m/min to accommodate different plant types

- Fine Tuning: Precise control allows operators to find the perfect speed for each product type

- Process Matching: Can synchronize with upstream and downstream handling processes

- Seasonal Adjustment: Speed can be adjusted based on seasonal product mix

- Worker Comfort: Can be set to optimal speeds for worker loading and unloading

This adjustable speed capability allows operators to find the perfect balance between throughput and gentle handling for each specific plant variety.

Continuous Support for Stability

The roller configuration of the powered conveyor provides ideal support for plant containers:

- Close Roller Spacing: Prevents small pots from tipping between rollers

- Full-Width Support: Distributes weight evenly across the container bottom

- Alignment Maintenance: Keeps boxes and trays properly oriented during transport

- Smooth Transitions: Maintains consistent support when moving between conveyor sections

- Multi-Size Accommodation: Handles everything from seed trays to gallon containers without adjustment

This consistent support is essential for preventing the tipping and shifting that commonly damages potted plants during transport.

Adaptable Configuration for Changing Needs

Horticultural operations have highly seasonal needs that require flexible equipment:

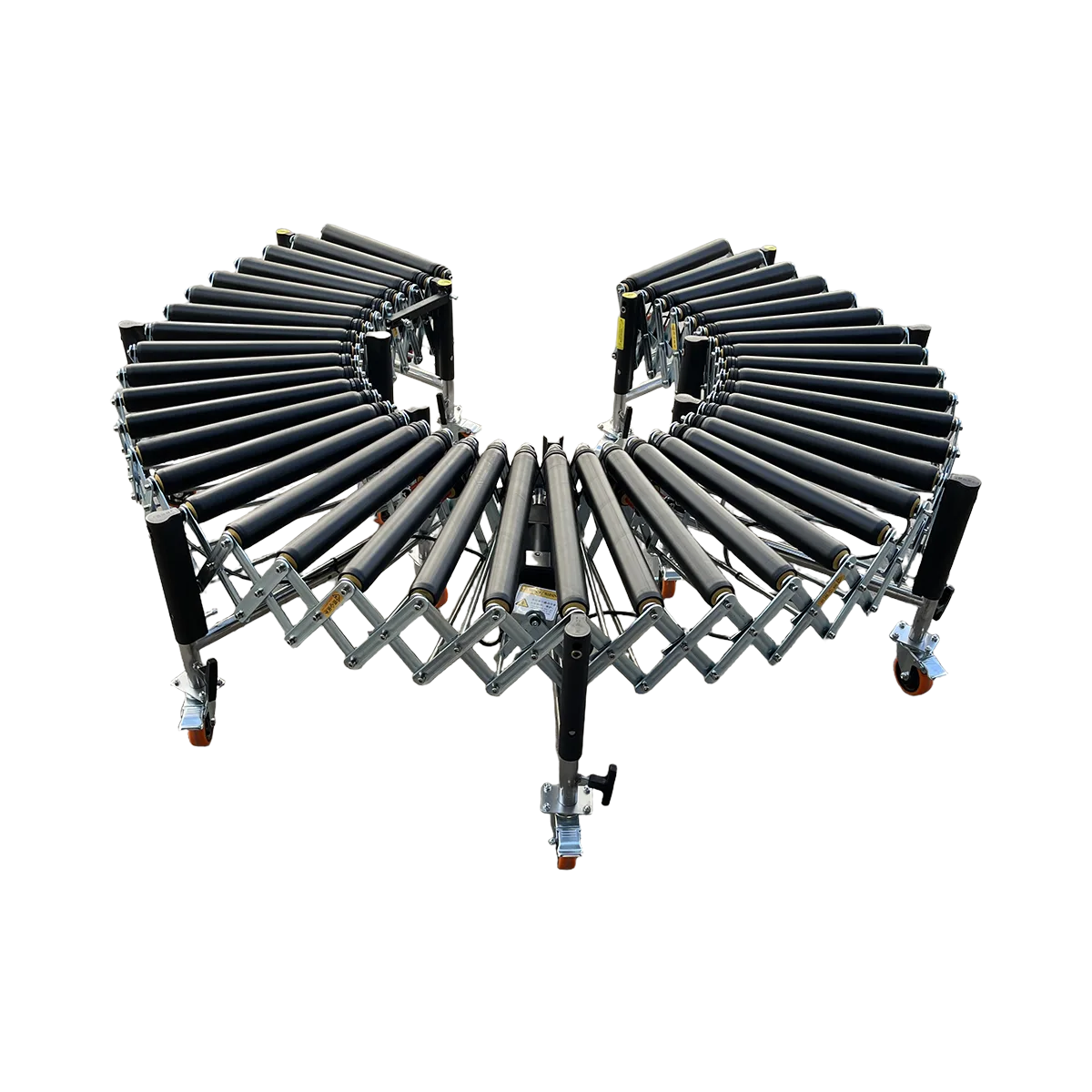

- Expandable Design: Each section extends from 525mm to 1500mm, adapting to changing space requirements

- Modular Connectivity: Multiple sections can be linked to create custom paths

- Height Adjustment: Support legs adjust from 450mm to 1500mm to match various work surfaces

- Width Options: Available in 500/600/800mm widths to accommodate different tray sizes

- Mobility: Heavy-duty casters allow for reconfiguration as seasonal needs change

This adaptability allows the system to evolve with changing product mixes and seasonal production volumes.

Practical Application in Nursery and Distribution Operations

The O-belt powered roller conveyor creates an efficient workflow for moving live plants through various facility processes:

Greenhouse to Processing Area Movement

For moving plants from growing areas to preparation zones:

- Harvesting Connection: Conveyor positioned at the end of growing benches receives freshly picked plants

- Central Processing: Products move smoothly to central processing areas for grading and preparation

- Climate Transition: Provides quick transfer between climate-controlled zones

- Minimal Handling: Reduces the number of manual touch points in the process

- Flow Regulation: Controls the pace of product movement to match worker capacity

This application minimizes the time plants spend in transition, preserving quality and reducing labor requirements.

Packing Line Integration

For facilitating efficient plant packaging operations:

- Workstation Supply: Delivers plants to packing stations at a controlled pace

- Material Coordination: Can be configured to deliver both plants and packaging materials

- Quality Control Points: Creates natural inspection points in the workflow

- Worker Ergonomics: Adjustable height reduces bending and reaching during packing

- Output Consistency: Maintains steady flow to optimize worker productivity

This integration creates a smooth, efficient packing process that reduces worker fatigue while maintaining gentle product handling.

Loading Dock Operations

For final movement to shipping vehicles:

- Order Assembly: Plants gathered from storage areas placed on conveyor

- Final Inspection: Products pass quality check stations at controlled speed

- Direct Loading: Conveyor extends to delivery vehicle for minimal handling

- Weather Protection: Minimizes plant exposure to outdoor conditions

- Loading Efficiency: Creates organized loading sequence for optimal vehicle packing

This streamlined approach reduces the time plants spend on the loading dock, minimizing exposure to non-ideal conditions while improving loading efficiency.

Benefits for Horticultural Operations

Implementing an O-belt powered roller conveyor system delivers multiple measurable benefits:

Significant Reduction in Plant Damage

- 30-50% Decrease: Typical reduction in handling-related damage compared to manual methods

- Bloom Preservation: Gentle handling maintains flower quality and appearance

- Foliage Protection: Reduced contact and abrasion preserves leaf quality

- Container Integrity: Fewer tipped pots means less soil spillage and root exposure

- Packaging Protection: Maintains the appearance of decorative pots and retail packaging

For operations where product appearance directly impacts retail value, this damage reduction translates directly to higher sellable percentages and reduced waste.

Improved Worker Efficiency and Ergonomics

- Labor Reduction: 20-30% fewer labor hours required for the same throughput

- Reduced Fatigue: Workers expend less physical energy throughout shifts

- Injury Prevention: Decreases repetitive motion injuries associated with manual handling

- Consistent Pace: Establishes a steady workflow rhythm that improves productivity

- Work Comfort: Adjustable height reduces bending and awkward postures

These improvements translate to lower labor costs, reduced turnover, and decreased workers’ compensation claims.

Enhanced Product Freshness and Quality

- Faster Processing: Reduces time from harvest to shipping by 40-60%

- Climate Control: Minimizes time spent outside optimal environmental conditions

- Stress Reduction: Gentle handling reduces physical stress on plants

- Consistent Handling: Standardizes the movement process for all workers

- Reduced Ethylene Exposure: Faster processing minimizes exposure to damaging ethylene gas

These quality benefits extend plant shelf life and customer satisfaction with the final product.

Implementation Considerations for Nursery Applications

When integrating an O-belt powered roller conveyor into a horticultural operation, several factors should be considered:

Environmental Adaptations

Horticultural environments present unique challenges for equipment:

- Moisture Resistance: Consider stainless steel rollers for consistently wet environments

- Cleaning Requirements: Select configurations that facilitate regular cleaning and sanitizing

- Temperature Variations: Ensure system can operate in both hot greenhouse and cooled packing areas

- Chemical Exposure: Consider resistance to fertilizers and plant treatments

- Outdoor Transitions: Plan for weather protection at building entry/exit points

These adaptations ensure long equipment life in the challenging conditions typical of plant production.

Workflow Integration

For maximum benefit, the conveyor system should enhance existing processes:

- Process Mapping: Document current workflow before designing conveyor layout

- Bottleneck Identification: Target areas where manual handling currently creates delays

- Traffic Patterns: Plan paths that minimize crossing worker walkways

- Growth Planning: Allow space for additional sections as production expands

- Seasonal Considerations: Create configurations that can adapt to seasonal changes

A thoughtfully designed layout maximizes return on investment by addressing the most problematic handling points first.

Training and Adoption

Proper training ensures maximum benefit from the new equipment:

- Speed Setting Guidelines: Establish optimal speed settings for different plant types

- Loading Techniques: Train proper placement methods to maximize stability

- Maintenance Routines: Establish regular cleaning and inspection schedules

- Reconfiguration Protocols: Document procedures for seasonal layout changes

- Troubleshooting Skills: Train key personnel on basic system adjustments

Clear procedures and proper training maximize the benefits while minimizing potential issues.

Return on Investment Analysis

For nurseries and plant distributors, investment in an O-belt powered roller conveyor typically delivers rapid returns:

- Damage Reduction: 30-50% decrease in handling-related product damage

- Labor Efficiency: 20-30% reduction in handling labor requirements

- Throughput Increase: 40-60% improvement in processing speed

- Space Utilization: 15-25% more efficient use of workspace

- Season Extension: Faster processing can extend selling seasons for time-sensitive products

Most horticultural operations handling 1,000+ plants daily can achieve full return on investment within 12-18 months through these combined savings and improvements.

Conclusion: A Gentle Touch for Horticultural Logistics

In the plant and flower industry, where products are simultaneously fragile, time-sensitive, and of variable dimensions, investing in the right handling equipment is critical to operational success. The O-belt driven powered roller conveyor, with its gentle drive system and precise speed control, represents an ideal solution that addresses the unique challenges of handling live plants.

By implementing this specialized conveyor for fragile goods, horticultural operations can significantly reduce damage, improve worker efficiency, and extend product freshness. The result is a more profitable operation where delicate plants move safely from growing areas to shipping vehicles with minimal stress and maximum care.

Frequently Asked Questions

What makes the O-belt drive system better for plant handling compared to other conveyor drive types?

The O-belt drive provides smoother acceleration and deceleration, generating less vibration than multi-wedge belt or chain drive systems. This gentler movement prevents soil shifting in pots and reduces stress on delicate stems and blooms. The system also runs more quietly, creating a better working environment in nursery settings where communication between workers is important.

How does a powered roller conveyor help maintain plant quality compared to manual handling?

Powered roller conveyors provide consistent, gentle movement without the jarring, lifting, and setting down that occurs with manual handling. This reduces physical stress on plants and prevents damage to leaves, stems, and flowers. The conveyor also moves products more quickly through the facility, reducing exposure to non-ideal environmental conditions that can affect plant health and longevity.

What speed settings are typically used for different types of horticultural products?

For delicate seedlings and flowering plants, speeds of 5-15 m/min are typically optimal. Medium-sized potted plants usually move efficiently at 15-25 m/min. Larger, more robust plants and boxed trees can typically handle speeds of 20-30 m/min. The variable speed control allows operations to find the perfect balance between gentle handling and efficient throughput for each product type.

Can the conveyor system be used in humid greenhouse environments?

Yes, but proper specification is important. For consistently humid environments, stainless steel rollers and frames are recommended over standard galvanized options. Regular maintenance is also critical, with more frequent lubrication of bearings and inspection of electrical components. With proper specification and maintenance, the system performs well in the high-humidity conditions typical of greenhouse operations.

How difficult is it to reconfigure the conveyor system for seasonal changes in production?

The modular design makes reconfiguration straightforward. Each section includes locking casters for mobility, and sections connect with simple fasteners that don’t require specialized tools. A typical reconfiguration can be completed by two workers in 1-2 hours. Many operations develop 2-3 standard layouts for different seasonal needs, allowing quick switching between configurations as production changes throughout the year.

Table of Contents

Recent Posts

Discover effective solutions for conveyor system integration between fixed sorters and loading docks. Bridge the automation gap with flexible, mobile conveyor systems for seamless logistics.

Master seasonal warehouse solutions with our peak season logistics guide. Learn how to expand loading capacity, manage high volumes, and implement flexible systems when you need them most.

Discover the most efficient frozen goods conveyor system for loading refrigerated trucks while maintaining cold chain integrity at your cold storage warehouse.

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.