The Pet Food Distributor’s Guide to Unloading Heavy Bags with a Conveyor

Streamline your pet food warehouse operations with specialized conveyor systems for heavy bags. Our hydraulic and rubber roller conveyor combo maximizes efficiency and safety.

Related Products

-

Hydraulic Conveyor – Large – 7900 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Hydraulic Conveyor – Medium – 7000 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Hydraulic Conveyor – Small – 5400 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

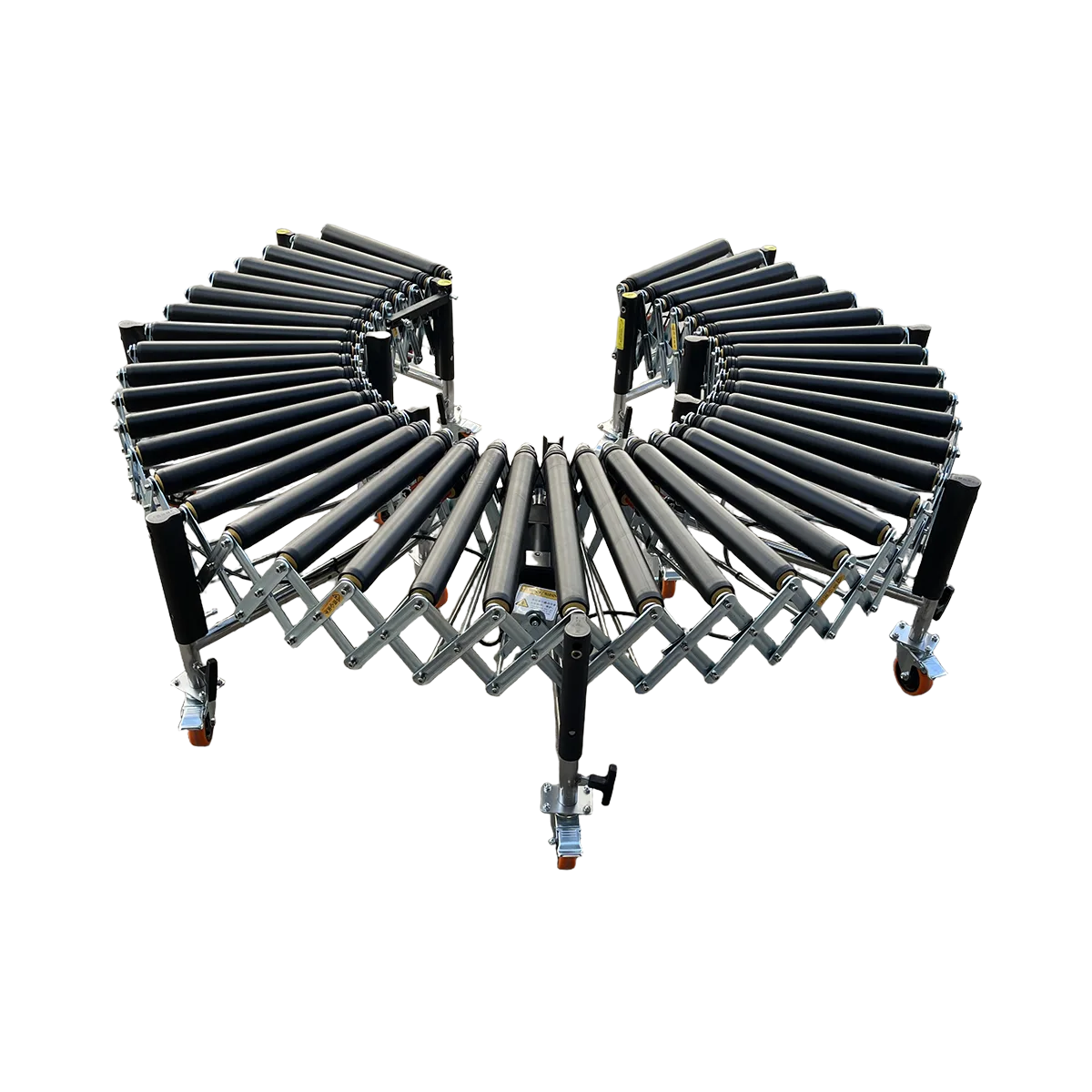

Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

The pet food industry presents unique material handling challenges, with products typically packaged in heavy bags weighing between 15-25kg. Efficiently moving these dense, awkward packages through warehouses and onto delivery vehicles requires specialized equipment. A properly designed pet food warehouse conveyor system can dramatically reduce labor costs, minimize worker injuries, and increase throughput in distribution facilities handling these challenging products. This guide examines the most effective conveyor solutions for pet food operations and how they can transform your unloading process.

The Ground-Level Challenge in Pet Food Distribution

Pet food distributors face a common logistical hurdle: how to efficiently move heavy bags from ground level up into trucks or elevated warehouse platforms without causing worker strain or product damage. This challenge is particularly acute in facilities that:

- Lack dedicated loading docks

- Process multiple truck deliveries throughout the day

- Handle various bag sizes from different manufacturers

- Operate with limited staff resources

- Must maintain high throughput rates

Traditional material handling methods often fall short when dealing with pet food bags:

| Method | Limitations with Pet Food Bags |

|---|---|

| Manual lifting | High injury risk, slow process, labor-intensive |

| Standard inclined conveyors | Bags slip backward on inclines, creating jams |

| Forklifts with pallets | Requires palletizing/depalletizing, inefficient for individual bags |

| Vertical lifts | Limited throughput, requires significant floor space |

The core challenge lies in the combination of weight and packaging material. Pet food bags typically feature slick outer surfaces designed for shelf appeal rather than material handling, creating a tendency to slip on standard conveyor belts—especially when positioned at the inclines necessary to reach truck heights.

The Physical Toll on Workers

Without proper equipment, pet food distribution becomes physically demanding work:

- A typical worker might handle hundreds of 15-25kg bags per shift

- Repeated lifting from floor level to truck height (typically 1.2-1.5m)

- Awkward gripping surfaces on slippery bag materials

- Twisting and reaching motions that increase injury risk

- Fatigue that builds throughout the shift, raising accident potential

These conditions lead to higher turnover rates, increased injury claims, and lower overall productivity—problems that the right conveyor system can directly address.

The Naili ‘Bag Lifting’ System: A Purpose-Built Solution

After evaluating the specific requirements of pet food distribution, a specialized combination system emerges as the optimal solution: the hydraulic conveyor and powered rubber roller conveyor integration. This purpose-designed setup addresses the unique challenges of handling heavy bags on inclines.

Part 1: The Hydraulic Conveyor Foundation

The hydraulic conveyor serves as the adjustable base of the system, providing:

- Adjustable incline: Hydraulic cylinders allow precise height adjustment to match truck beds or platform heights (700mm to 2400mm, depending on model)

- Stable framework: Heavy-duty construction supports the weight of both the conveyor system and loaded pet food bags

- Flexible positioning: Can be easily positioned where needed in the warehouse or loading area

- Powerful lifting capacity: 5-ton hydraulic cylinder capacity ensures stable, reliable performance

The key benefit of the hydraulic conveyor is its ability to create a bridge between ground level and elevated loading points, providing the necessary incline while maintaining structural stability. This creates the foundation for the bag handling portion of the system.

For pet food operations, the Small or Medium hydraulic conveyor models typically provide the ideal balance of capacity and maneuverability:

- Small model (4000mm): Perfect for operations with limited space or primarily handling delivery vans

- Medium model (7000mm): Ideal for facilities loading standard delivery trucks and shipping containers

Part 2: The Powered Rubber Roller Conveyor for Secure Bag Transport

Mounted on the inclined portion of the hydraulic conveyor, the powered rubber roller conveyor provides the critical bag-handling capability:

- Grippy surface: Polyvinyl chloride coated rollers provide superior friction that prevents bags from sliding backward

- Powered operation: Motor-driven rollers actively move bags upward, eliminating the need for manual pushing

- High load capacity: Supports up to 120kg per meter, easily handling the heaviest pet food bags

- Optimized roller spacing: 57mm spacing ensures even the smallest bags move smoothly without getting caught

This specialized conveyor is particularly important for pet food applications because of its unique attributes that address the specific challenges of bag handling:

- Superior grip: The rubber coating provides 30-40% more friction than standard metal rollers, preventing the backward sliding that plagues other systems

- Gentle handling: The rubberized surface reduces the risk of bag punctures, protecting valuable product

- Consistent movement: Powered operation ensures steady, controlled movement even with varying bag weights

For pet food operations handling bags over 20kg, the rubber roller conveyor is particularly essential, as noted in the product specifications.

Preventing Backward Sliding: The Key to Efficient Inclined Transport

The critical advantage of this integrated system is its ability to overcome the backward sliding problem that makes many standard conveyors unsuitable for bagged pet food. This issue occurs because:

- Pet food bags typically have smooth, sometimes glossy surfaces

- The weight of the bags creates significant downward force on inclines

- Standard metal or plastic rollers provide insufficient friction to counteract gravity

- The shifting contents within bags can cause sudden weight distribution changes

The combination of hydraulic incline and rubber rollers solves this problem through:

- Dual-surface contact: Bags make contact with multiple rubber rollers simultaneously, maximizing grip

- Powered movement: Active roller rotation overcomes gravitational resistance

- Optimal incline angle: The hydraulic system allows for setting the gentlest effective incline

- Speed control: Adjustable conveyor speed ensures bags move at the optimal pace for stability

This specialized design prevents the jams, backsliding, and manual intervention that plague operations using standard conveyors for this application.

Implementation in Pet Food Distribution Operations

The hydraulic and rubber roller conveyor combination fits seamlessly into pet food distribution workflows:

Loading Process

- Position the hydraulic conveyor at the loading point

- Adjust height to match truck bed or warehouse platform

- Place pet food bags on the lower end of the conveyor

- Bags travel up the powered rubber roller section without slipping

- Worker at the top receives and arranges bags in the truck or on pallets

Unloading Process

- Position the hydraulic conveyor at the truck door

- Adjust height to align with the truck bed

- Reverse the conveyor direction

- Worker in the truck places bags on the conveyor

- Bags travel down to ground level in a controlled manner

- Receiving worker removes bags for storage or further processing

This system typically enables two workers to unload a full truckload of pet food bags in 30-40% less time than manual methods, while dramatically reducing physical strain.

Ideal Applications Beyond Pet Food

While especially effective for pet food distribution, this conveyor combination excels in handling a variety of bagged products:

- Agricultural supplies: Feed, seed, and fertilizer bags

- Building materials: Cement, sand, and aggregate bags

- Food service: Bulk grain, flour, and sugar bags

- Chemical products: Granular chemicals in heavy-duty bags

- Home improvement: Soil, mulch, and landscape material bags

Any operation dealing with heavy bags on inclines can benefit from the same key advantages that make this system ideal for unloading dog food bags.

Practical Considerations for Implementation

When implementing this system in a pet food distribution facility, several factors should be considered:

Space Requirements

- Allow sufficient clearance for the extended hydraulic conveyor length (4000-7000mm)

- Ensure adequate width for the conveyor plus worker access (typically 1.5-2m total)

- Consider storage space when the system is not in use

Power Supply

- Standard 380V or 220V power connection (380V three-phase recommended for optimal performance)

- Placement of power outlets in loading areas

- Potential need for extension cables if loading positions vary

Throughput Capacity

For pet food operations, the system typically handles:

- 1500-2000 heavy bags (15-25kg) per hour

- This capacity aligns with most pet food distribution requirements

Worker Training

While the system is straightforward to operate, basic training ensures optimal results:

- Proper bag placement on the conveyor

- Height adjustment procedures

- Speed control for different bag types

- Basic troubleshooting techniques

Return on Investment for Pet Food Distributors

The financial case for implementing this specialized conveyor system is compelling for pet food operations:

- Labor savings: Reduces required personnel by 30-50% for loading/unloading tasks

- Injury reduction: Minimizes costly worker compensation claims and lost productivity

- Increased throughput: Enables faster truck turnaround and higher daily shipment capacity

- Product protection: Reduces damage to valuable pet food products

- Equipment longevity: 5-10 year operational lifespan with minimal maintenance requirements

For operations handling over 1,000 pet food bags daily, the typical ROI period is 6-12 months through labor savings and efficiency improvements alone.

Conclusion: Transforming Pet Food Logistics

The pet food industry’s unique handling challenges require specialized solutions. The combination of hydraulic conveyor base and powered rubber roller conveyor creates an inclined bag loader system that specifically addresses these needs, turning a difficult manual task into a simple, automated process.

By implementing this purpose-built system, pet food distributors can:

- Protect workers from injury-causing manual handling

- Increase operational efficiency and throughput

- Reduce labor costs while improving working conditions

- Handle the full range of bag sizes common in the pet food industry

This specialized approach to material handling represents a significant advance over general-purpose conveyor systems, providing pet food operations with the specific functionality needed to address their unique challenges.

Frequently Asked Questions

What is the maximum weight of pet food bags this system can handle?

The hydraulic and rubber roller conveyor combination can safely handle bags weighing up to 50kg, covering the entire range of pet food packaging from small 5kg bags to bulk 25kg bags. The rubber roller conveyor supports 120kg per meter, allowing multiple heavy bags to be on the conveyor simultaneously.

How steep of an incline can this system achieve without bags sliding backward?

Thanks to the rubber roller surface, the system can safely operate at inclines up to 30 degrees without bag slippage. However, for optimal operation with heavy pet food bags, we typically recommend operating at 15-20 degree inclines to balance efficiency with stability.

Can this system handle different sizes of pet food bags on the same line?

Yes, the 57mm roller spacing on the rubber roller conveyor can accommodate everything from small 2kg specialty pet food bags to large 25kg bulk bags without adjustment. The rubber surface provides consistent grip regardless of bag dimensions.

What maintenance is required for the rubber roller conveyor portion?

Maintenance is minimal, typically involving monthly checks of belt tension, quarterly bearing lubrication, and occasional cleaning of the rubber rollers to maintain optimal grip. With proper maintenance, the system provides 5-10 years of reliable service even in high-volume pet food operations.

Can this conveyor system be moved between different loading areas?

Yes, both components feature lockable casters that allow the system to be repositioned as needed. The hydraulic conveyor includes heavy-duty wheels (50mm width, 200mm height) that support the weight of the combined system, allowing relocation with minimal effort.

Table of Contents

Recent Posts

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.

Discover how mobile powered roller conveyors transform cross-docking efficiency, creating adaptable “land bridges” that accelerate freight movement between loading docks while minimizing manual handling and labor costs.

Discover how a high-capacity conveyor for tiles can transform your flooring warehouse logistics with efficient solutions for handling these exceptionally dense materials.