Telescopic Conveyor Manufacturer

Home > Telescopic Conveyor

Discover premium telescopic conveyor solutions from a leading telescopic conveyor manufacturer. Our extendable systems deliver efficient loading/unloading for all logistics needs.

Our Telescopic Conveyor Products

60 kg/m

Length Range

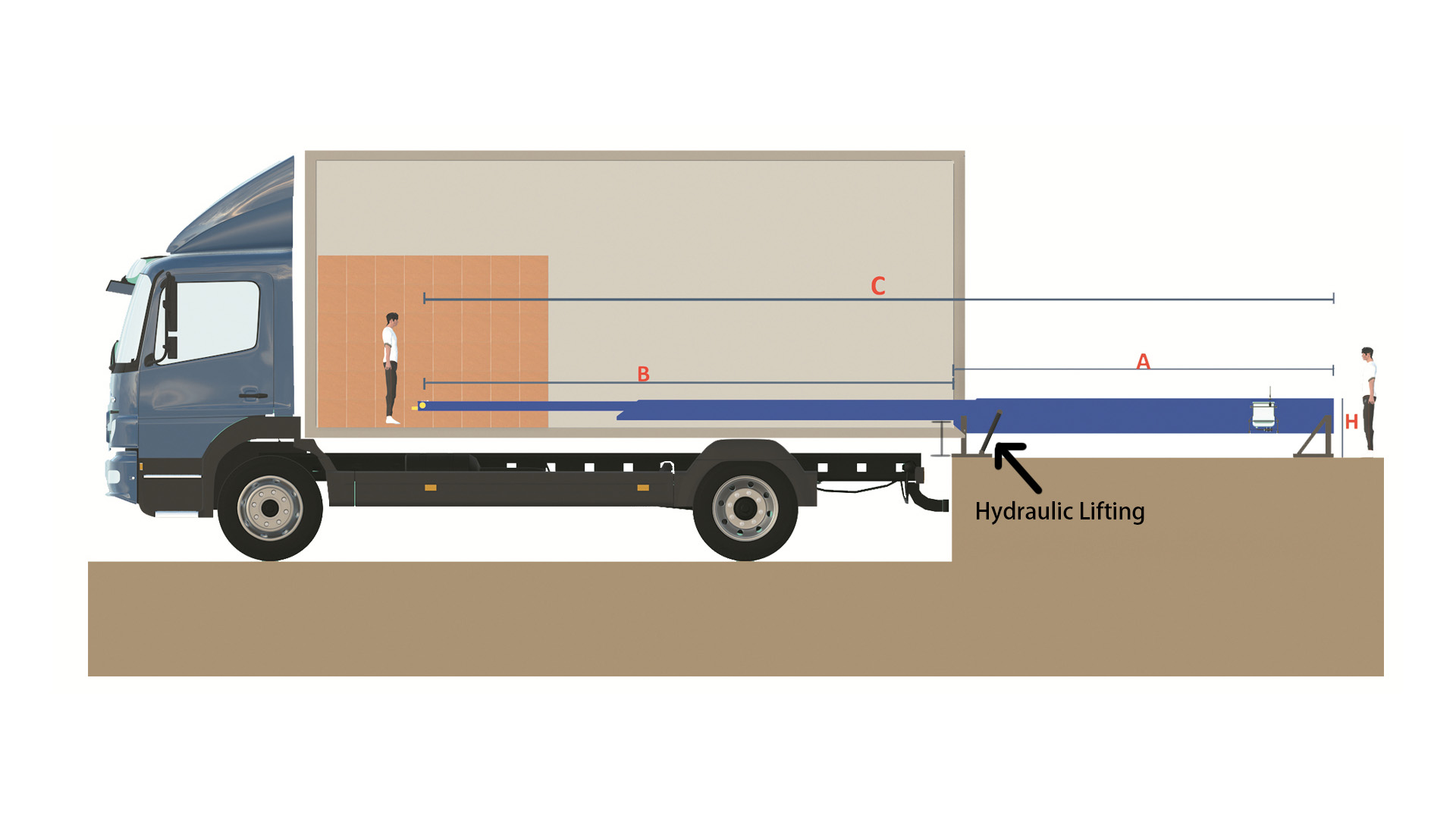

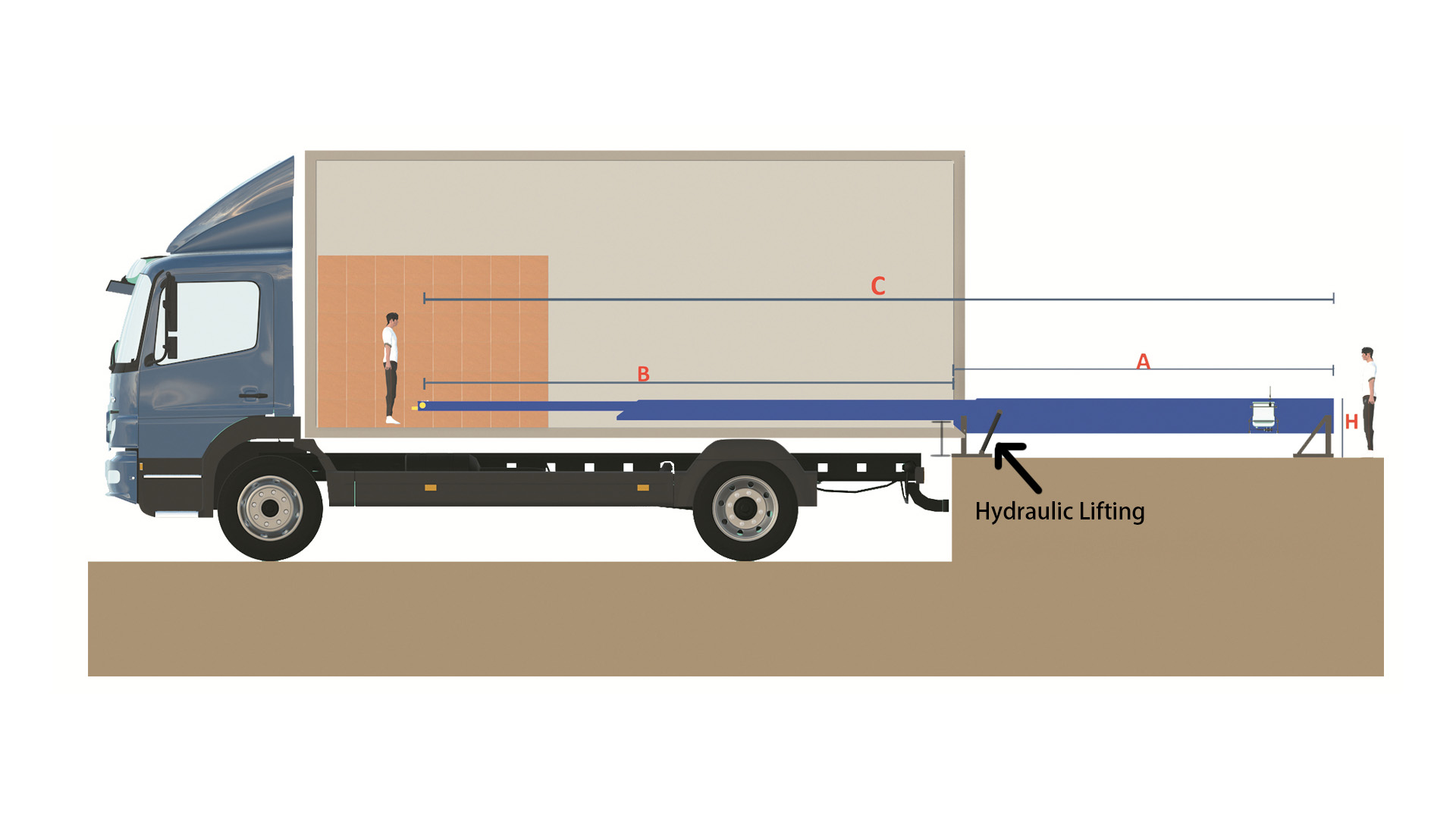

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 6000 | 16000 | 22000 |

| 7000 | 17000 | 24000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 5000 | 9000 | 14000 |

| 6000 | 12000 | 18000 |

| 7000 | 14000 | 21000 |

| 8000 | 17000 | 25000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 4000 | 5000 | 9000 |

| 5000 | 7000 | 12000 |

| 6000 | 8000 | 14000 |

| 6000 | 8500 | 14500 |

| 7000 | 9000 | 16000 |

| 7000 | 9500 | 16500 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 3000 | 2000 | 5000 |

| 4000 | 3000 | 7000 |

| 5000 | 4000 | 9000 |

| 6000 | 5000 | 11000 |

| 7000 | 6000 | 13000 |

Flat-bottomed Goods

Bagged Goods

Telescopic conveyors represent the pinnacle of efficient material handling technology in today’s logistics and transportation industries. As a professional telescopic conveyor manufacturer, we offer versatile extending conveyor systems that dramatically improve loading and unloading operations. These innovative systems feature multiple extendable sections that can reach deep into containers or trucks, eliminating the need for workers to manually carry items over long distances.

A telescopic boom conveyor creates a direct bridge between your storage facility and transportation vehicles, allowing for continuous product flow that significantly reduces labor requirements while increasing throughput capacity. Whether you’re managing a distribution center, operating a manufacturing facility, or running a busy warehouse, telescopic conveyors provide the flexibility and efficiency needed to optimize your material handling operations.

Key Features of Telescopic Conveyors

Our telescopic conveyor systems are engineered for maximum operational efficiency and durability:

Variable Extension Capability

Telescopic conveyors are available in multiple configurations to match your specific operational requirements:

- 2-section models: Extend up to 10 meters, ideal for smaller trucks and limited spaces

- 3-section models: Reach up to 16 meters, perfect for standard containers

- 4-section models: Extend up to 25 meters, reaching the full depth of containers

- 5-section models: Our most extensive option, reaching up to 24 meters when fully extended

This variable extension capability ensures you can efficiently load and unload vehicles of any size, from small delivery vans to full-sized shipping containers.

Bidirectional Operation

Every telescopic boom conveyor features bidirectional operation, allowing the system to:

- Transport materials into vehicles for efficient loading

- Move products out of vehicles for streamlined unloading

- Switch directions instantly with simple controls

- Maintain consistent speed in either direction

This versatility makes our telescopic conveyors ideal for facilities that handle both incoming and outgoing shipments.

Adjustable Height System

Our telescopic conveyors accommodate various loading dock configurations and vehicle heights:

- Height adjustment range from 610mm to 900mm depending on model

- Compatible with standard loading docks

- Works effectively even without dedicated loading platforms

- Optional hydraulic lift systems for environments without fixed loading docks

The ability to adjust working height ensures seamless operation across diverse loading scenarios.

Robust Load Capacity

Engineered for industrial applications, our telescopic conveyors offer impressive load-bearing capabilities:

- Standard capacity of 60 kg/m²

- Even weight distribution across the conveyor belt

- Stable performance even with variable load placement

- Suitable for most standard packaging types and configurations

This capacity meets the needs of most logistics operations while maintaining system longevity and reliability.

Telescopic Conveyor Models

As a leading telescopic conveyor supplier, we offer a comprehensive range of models to suit various operational requirements:

600mm Width Series

| Model | Fixed Length (m) | Extension (m) | Total Length (m) | Belt Width (mm) | Body Height (mm) |

|---|---|---|---|---|---|

| NLS-2-3/2 | 3 | 2 | 5 | 600 | 610 |

| NLS-2-5/3 | 5 | 3 | 8 | 600 | 610 |

| NLS-2-6/4 | 6 | 4 | 10 | 600 | 610 |

| NLS-3-5/7 | 5 | 7 | 12 | 600 | 800 |

| NLS-3-6/8 | 6 | 8 | 14 | 600 | 800 |

| NLS-3-7/9 | 7 | 9 | 16 | 600 | 800 |

| NLS-4-6/12 | 6 | 12 | 18 | 600 | 850 |

| NLS-4-7/14 | 7 | 14 | 21 | 600 | 850 |

| NLS-4-8/17 | 8 | 17 | 25 | 600 | 850 |

| NLS-5-6/16 | 6 | 16 | 22 | 600 | 900 |

| NLS-5-7/17 | 7 | 17 | 24 | 600 | 900 |

800mm Width Series

We also offer an 800mm width series with identical extension specifications for operations requiring wider conveyor belts.

Benefits of Telescopic Conveyor Systems

Investing in a quality telescopic conveyor delivers significant operational advantages:

Enhanced Efficiency

- Time Reduction: Decreases loading/unloading times by up to 70% compared to manual methods

- Labor Optimization: Typically requires only 2-3 workers to manage the entire loading/unloading process

- Continuous Operation: Maintains steady product flow without interruptions

- Faster Vehicle Turnaround: Reduces dock occupancy times, allowing more vehicles to be processed

Reduced Physical Strain

- Elimination of Manual Carrying: Workers no longer need to repeatedly enter and exit containers

- Injury Prevention: Significantly reduces risk of back injuries and repetitive strain issues

- Improved Working Conditions: Creates a more ergonomic and comfortable work environment

- Lower Fatigue: Maintains worker productivity throughout shifts

Increased Throughput

- Higher Processing Volume: Handle more shipments in less time

- Consistent Performance: Maintains steady operation regardless of package variety

- Process Integration: Easily connects with existing warehouse management systems

- Scalable Solution: Adapts to growing business needs without proportional labor increases

Product Protection

- Gentle Handling: Smooth conveyor surface prevents product damage

- Controlled Movement: Consistent speed prevents impacts between packages

- Weather Protection: Reduces exposure of goods to external elements during loading

- Reduced Drops: Eliminates manual transfers that can lead to dropped items

As a professional telescopic conveyor factory, we focus on designing systems that deliver these benefits through quality engineering and construction.

Optional Features

Customize your telescopic boom conveyor with these optional features:

- Hydraulic Lift System: Adjusts incline angle, making it easier to load/unload from the top of cargo areas

- Operation Platform: Installed at the truck entry end, allowing operators to stand higher for better access

- Powered Wheels: Electric-powered wheels for easier positioning

- Manual Wheels: Economical mobility solution

- Counter System: Tracks the number of packages processed

- Overhead Scanner: Integrates barcode scanning functionality

- Rear End Ramp: Ideal solution when no loading dock is available

- Front End LED Lighting: Illuminates container/truck interiors for improved visibility

- Remote Control: Wireless control for distant operation and enhanced flexibility

Industries and Applications

Telescopic conveyors excel across numerous industries:

Logistics and Distribution

- Courier companies handling package sorting and distribution

- E-commerce fulfillment centers processing high package volumes

- Cross-docking facilities requiring rapid transfer between vehicles

- Mail processing centers managing varied package sizes

Manufacturing

- Production facilities shipping finished goods

- Assembly plants receiving component parts

- Food and beverage packaging operations

- Consumer goods manufacturing

Retail

- Distribution centers supplying retail locations

- Large retail backrooms receiving merchandise

- Seasonal operation centers handling volume spikes

- Returns processing facilities

Transportation

- Air cargo facilities loading unit load devices

- Port operations transferring goods between storage and vessels

- Rail terminals loading and unloading freight cars

- Intermodal transfer facilities

The versatility of telescopic conveyor systems makes them indispensable in virtually any environment requiring efficient vehicle loading and unloading.

Maintenance and Support

Our telescopic conveyors are designed for reliability and longevity:

- Installation Support: Detailed installation and commissioning video guides

- Remote Technical Assistance: Expert guidance for installation challenges

- Spare Parts Service: Complete parts delivery service for international customers

- Maintenance Schedule:

- Daily visual inspection

- Monthly light maintenance (cleaning, hardware inspection)

- Quarterly comprehensive maintenance (lubrication, electrical system checks)

- Key Replacement Parts:

- Conveyor belt: Replace every 2-3 years

- Bearings: Check/replace every 3-5 years

- Motor carbon brushes: Check/replace approximately every 5 years

- Hydraulic system seals (if equipped): Check/replace every 3-4 years

Integration with Other Systems

Our telescopic conveyors work seamlessly with various material handling solutions:

- Integrate with warehouse management systems for streamlined operations

- Connect with stationary conveyor lines using transition segments

- Pair with sortation systems for comprehensive material flow

- Combine with roller conveyor systems for extended reach and functionality

- Interface with automated packaging equipment for end-to-end processing

Frequently Asked Questions

What size telescopic conveyor do I need for my operation?

Choose based on your maximum extension requirement and container depth. For standard 40ft containers, a 4-section model with 12-17m extension capability is typically recommended. Consider both your current needs and potential future requirements.

Can telescopic conveyors operate in outdoor environments?

Standard models are designed primarily for indoor use. For outdoor or harsh environments (high humidity, salt spray, or corrosive substances), we offer specially treated models with waterproof electrical systems, stainless steel components, and enhanced corrosion protection, adding approximately 15-25% to the cost.

What is the installation time for a telescopic conveyor?

Installation typically takes 1-2 working days for 2-3 section models and 2-3 working days for 4-5 section models. We provide detailed installation videos and remote support to ensure smooth setup.

Does the telescopic conveyor require a fixed loading dock?

While ideal for use with standard loading docks, telescopic conveyors can be used without fixed platforms by adding a rear hydraulic climbing device and steel frame support to elevate the machine to container/truck height. Alternatively, consider our hydraulic conveyor line specifically designed for ground-to-vehicle elevation changes.

What is the expected return on investment for a telescopic conveyor?

ROI is typically excellent, with most systems paying for themselves within 12-18 months through labor savings (reducing 2-4 loading/unloading workers), 20-50% efficiency improvements, approximately 80% reduction in product damage, and significant decrease in workplace injuries and associated costs.

Conclusion

Telescopic conveyors represent a transformative solution for modern material handling operations. By implementing these advanced systems, businesses can dramatically improve loading and unloading efficiency while reducing labor requirements and physical strain on workers.

As a professional telescopic conveyor manufacturer, we are committed to providing high-quality, reliable systems tailored to your specific operational needs. Through innovative design, quality construction, and comprehensive support, our telescopic boom conveyor systems deliver exceptional performance and value throughout their operational life.