TeleScopic Conveyor – 4 Sections

The TeleScopic Conveyor – 4 Sections is an efficient and flexible solution for loading and unloading with adjustable speeds (10-40 m/min) and a load capacity of 60 kg/m². Powered by 2.2 kW and 0.75 kW motors, it extends up to 17,000 mm, making it perfect for various container sizes. The impact-resistant 3 mm PVK composite belt ensures durability, while customizable options like hydraulic lifts, operator platforms, and mobility casters enhance usability. Ideal for warehouses and docks, this conveyor boosts productivity with minimal maintenance.

Propduct Model

Key Parameters

Equipment Parameters

| Item | Parameters |

| Conveying Speed | 10-40 m/min (frequency adjustable) |

| Rated Load | ≤ 60 kg/m² |

| Motor | Conveying motor: 2.2 kW Taibang, Naixin<br>Telescoping motor: 0.75 kW Taibang, Naixin |

| Telescoping Speed | 10 m/min (frequency adjustable) |

| Belt | 3 mm PVK impact-resistant composite belt (steel buckle joint) |

| Electrical | 6 W/LED lighting × 2, Shengbang inverter (proportional to motor power), independent power distribution box, Chint electrical components |

| Cable Drag Chain | Cables: Dow (China), Jinhuan Yu, Jinlong Yu (copper conductors and wires), Drag Chain: Cargotec, Igus, Xin Pengrui |

| Bearing | Built-in bearings: Harbin/Renben, Bearing seat: TR/Renben/FSB |

| Optional Items | Hydraulic lift, operator platform, hump, electric casters, moving casters, counter, top sweep |

| Plate Thickness | Main beam: (fixed section) 6 mm and above BS700 or T700 and above steel plate bending (height 750 mm and above) Secondary beam: (first extending section) 6 mm and above BS700 or T700 and above steel plate bending (height 455 mm and above) Secondary beam: (second extending section) 5 mm and above BS700 or T700 and above steel plate bending (height 309 mm and above) Secondary beam: (third extending section) 5 mm and above BS700 or T700 and above steel plate bending (height 165 mm and above) |

| Drive Roller | Φ 180 × 850 seamless steel pipe precision manufacturing, surface rubber coating > 10 mm, wall thickness > 6 mm, spindle 45# steel quenching |

| Driven Roller | Φ 89 × 750 and 850 seamless steel pipe precision manufacturing, wall thickness > 5 mm, spindle 45# steel quenching, pressure belt roller Φ 50 mm |

| Hydraulics | Hydraulic angle: 3.5°, mounting hole distance 615 mm, stroke 285 mm |

Other Parameters

| Fixed Section (mm) | Max Extension (mm) | Height (mm) | Equipment Weight (t) |

| 5000 | 9000 | ≥ 760 | 2.1 |

| 6000 | 12000 | ≥ 760 | 2.4 |

| 7000 | 14000 | ≥ 760 | 2.7 |

| 8000 | 17000 | ≥ 760 | 3 |

Related Products

60 kg/m

Length Range

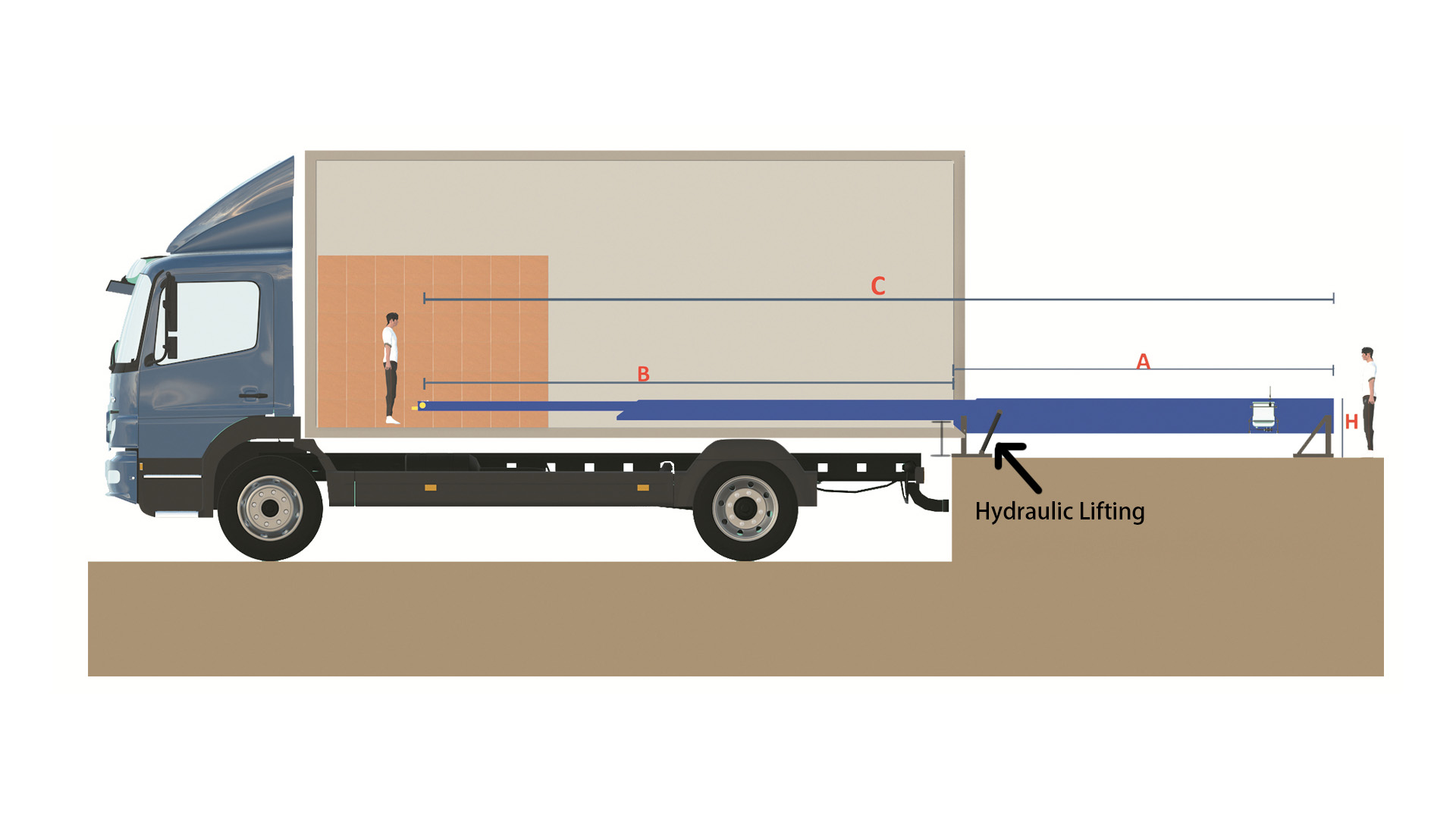

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 6000 | 16000 | 22000 |

| 7000 | 17000 | 24000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 4000 | 5000 | 9000 |

| 5000 | 7000 | 12000 |

| 6000 | 8000 | 14000 |

| 6000 | 8500 | 14500 |

| 7000 | 9000 | 16000 |

| 7000 | 9500 | 16500 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 3000 | 2000 | 5000 |

| 4000 | 3000 | 7000 |

| 5000 | 4000 | 9000 |

| 6000 | 5000 | 11000 |

| 7000 | 6000 | 13000 |

Flat-bottomed Goods

Bagged Goods