The Best Conveyor for E-commerce Fulfillment: Handling High-Volume, Mixed Parcels

Discover the ideal ecommerce conveyor system for handling diverse parcels at high volumes. Optimize your fulfillment center with flexible solutions that scale with demand.

Related Products

-

Gravity Skate Wheel Conveyor – 2100 mm/SectionCollapsed Length

420 mm

Extended Length2100 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

-

Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

-

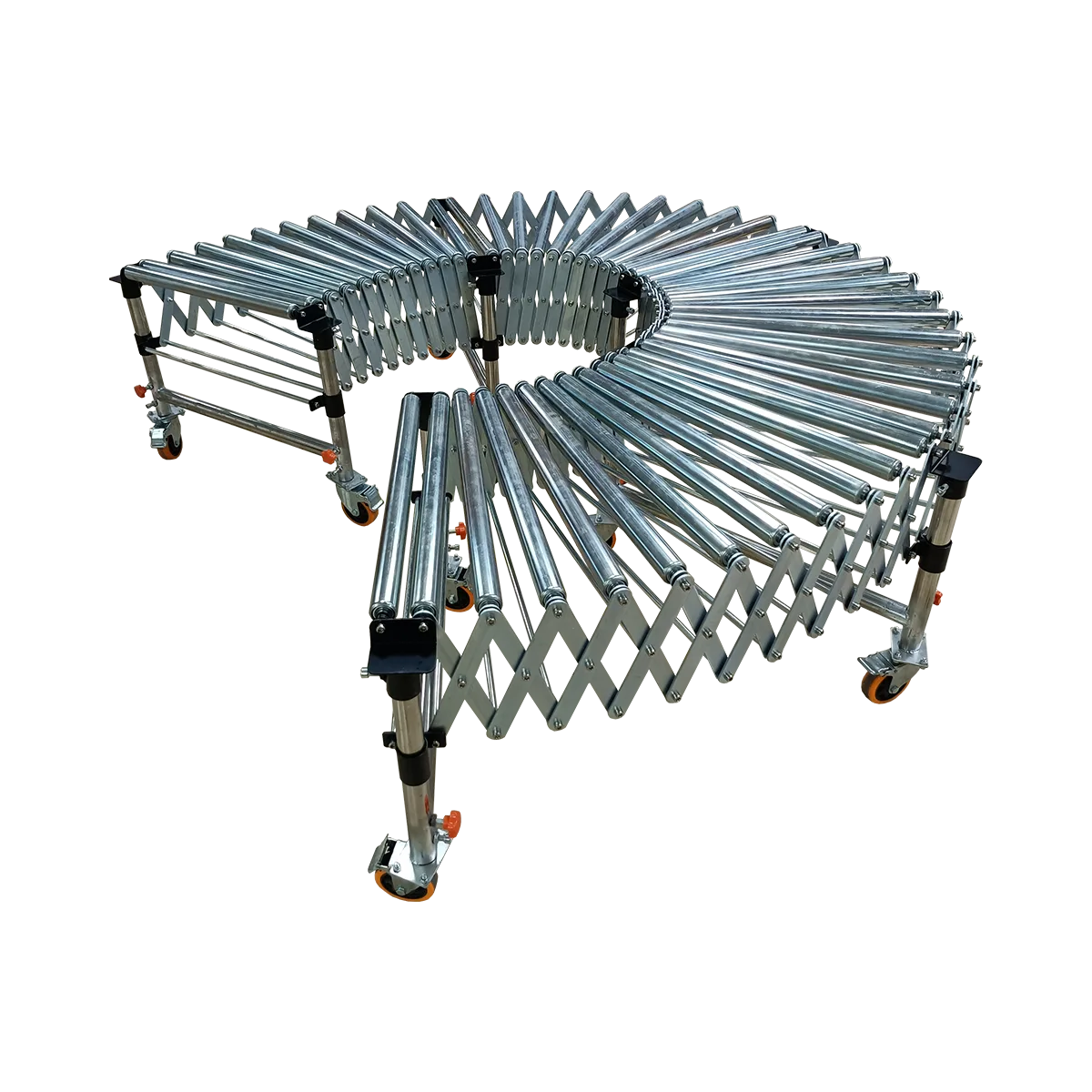

Gravity Roller Conveyor – Roller Diameter 50 mm – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

Today’s ecommerce conveyor system requirements stand in stark contrast to traditional retail distribution models. E-commerce fulfillment centers face the triple challenge of processing orders at unprecedented speeds, managing ever-increasing volumes, and handling remarkably diverse parcel sizes and weights—often all flowing through the same system simultaneously. Unlike traditional retail logistics where uniform cartons and predictable volumes were the norm, e-commerce operations must adapt to rapidly fluctuating demand patterns and an endless variety of product dimensions.

This fundamental shift has rendered many conventional conveyor solutions inadequate. Fixed, permanent installations that excel at moving uniform packages now struggle with the unpredictability of direct-to-consumer fulfillment. The most successful e-commerce operations have recognized that adaptability is no longer optional—it’s essential for survival in an industry where consumer expectations for rapid delivery continue to intensify while order profiles become increasingly diverse.

What today’s e-commerce businesses need is a scalable conveyor solution that can flex with seasonal demand spikes, adapt to changing parcel characteristics, and reconfigure quickly as operational requirements evolve—all while maintaining the speed and reliability that customers demand.

Key Challenge: Connecting Your Central Sorting Line to Multiple Loading Docks

The critical pain point in many fulfillment center conveyor operations isn’t the core sortation system itself, but rather the “last mile” within the facility—efficiently connecting central sorting operations to multiple shipping docks or staging areas. This challenge manifests in several specific ways:

The Distribution Bottleneck

After parcels have been picked, packed, and sorted by destination, they must be physically transported to the correct outbound truck or staging location. Without an effective conveyor connection strategy, operations often encounter:

- Labor-intensive manual transport processes

- Congested aisles as workers cross paths with carts and packages

- Uneven workload distribution across shipping doors

- Difficulty adapting when shipment volumes shift between carriers

The Space Utilization Problem

E-commerce fulfillment centers typically face significant space constraints:

- Available floor space between sorting areas and shipping docks is rarely a straight line

- Fixed building infrastructure (columns, fire doors, etc.) creates obstacles

- Seasonal operations may require temporary conveyor extensions

- Competing operational needs lead to constantly changing floor layouts

The Flexibility Challenge

The dynamic nature of e-commerce creates unique demands:

- Carrier allocation and dock assignments change frequently

- Peak seasons require additional capacity that sits idle during regular periods

- New shipping service launches can dramatically change outbound material flow

- Returns processing may need to share infrastructure with outbound operations

Traditional conveyor solutions with permanent, fixed installations simply cannot adapt quickly enough to these changing requirements. The ideal solution must combine the throughput capacity of powered systems with the adaptability of modular components that can be reconfigured as needed.

The Naili Solution: A ‘Hub and Spoke’ of Flexible Conveyors

A strategically designed “hub and spoke” conveyor configuration offers the optimal balance of throughput capacity, flexibility, and cost-effectiveness for e-commerce operations. This approach leverages Naili’s complementary conveyor technologies to create a system that can evolve with your business needs.

Using a Powered Roller Conveyor as the main ‘spine’ from your sorter.

The foundation of an effective e-commerce distribution system is a reliable, high-capacity main line that can efficiently move parcels from your central sorting operation. Naili’s powered roller conveyor serves as the ideal backbone for this application:

- Consistent throughput capacity: With speeds adjustable from 0.3-40 m/min and load capacities of 80-100 kg/m depending on model, these powered lines ensure steady, reliable flow regardless of package weight variation.

- Configurable lengths: Available in three main variants (O-belt driven 1500mm sections, multi-wedge belt driven 2000mm sections, and multi-wedge belt driven 3000mm sections), these powered lines can be configured to create a main transportation spine of virtually any length.

- Bidirectional capability: The ability to run forward or reverse direction makes these conveyors adaptable to changing workflows, including returns processing or recirculation needs.

- Adjustable height: Support leg options ranging from 450-1500mm accommodate various facility layouts and ensure proper connections to both sorting systems and outbound spurs.

For the main spine, the multi-wedge belt driven 2000mm sections offer the ideal balance of capacity (100 kg/m) and extension capability for most e-commerce applications. These sections provide the reliability needed for continuous operation during high-volume periods while maintaining reasonable energy consumption.

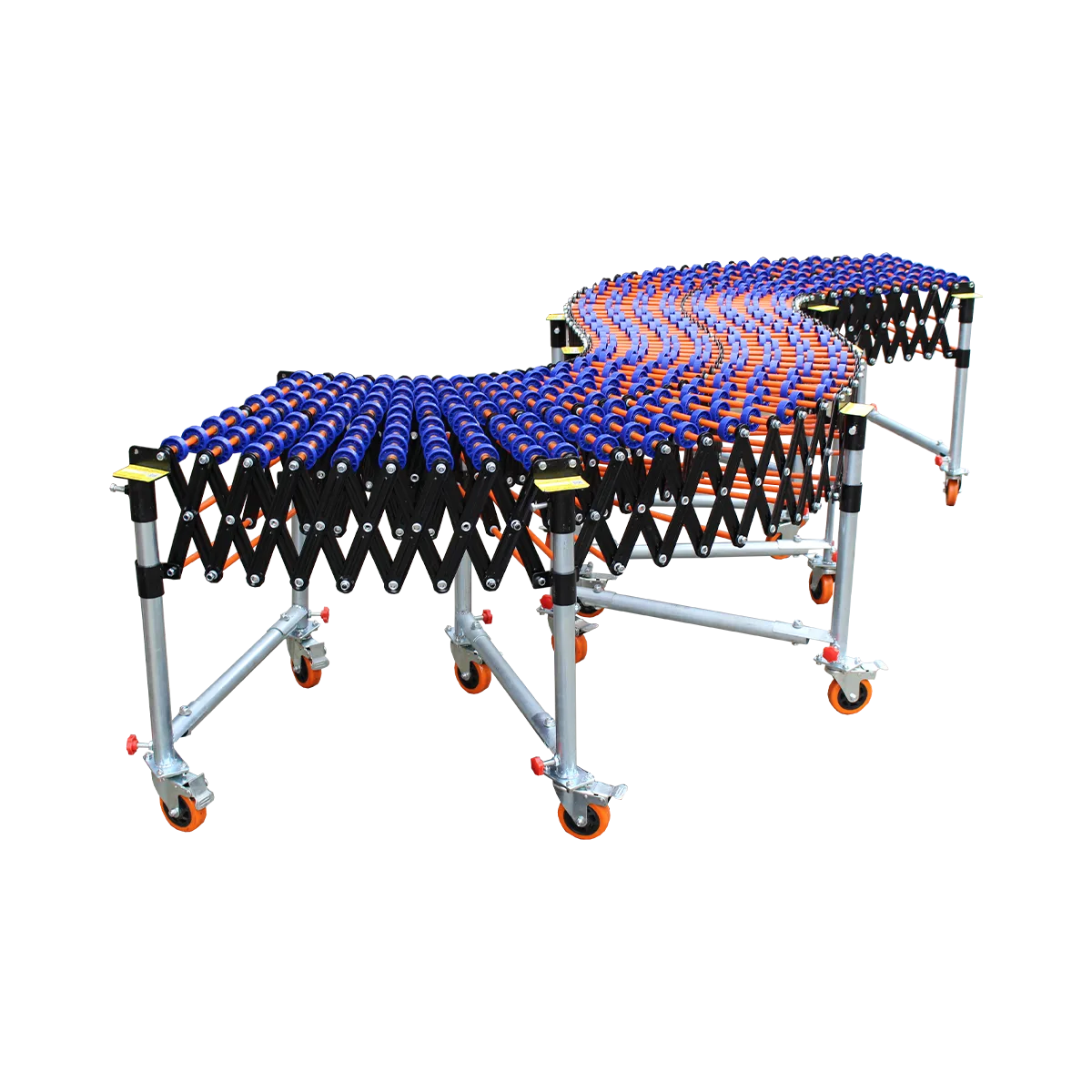

Branching off with multiple Gravity Skate Wheel Conveyors to different truck bays.

From the powered main line, gravity conveyor spurs create flexible pathways to multiple destination points. Naili’s Gravity Skate Wheel Conveyors are particularly well-suited for this role:

- Exceptional flexibility: With their remarkable 1:5 expansion ratio (collapsing from 2100mm extended length to just 420mm), these units can be quickly repositioned, extended, or shortened as needed.

- Lightweight construction: Approximately 30% lighter than roller conveyors, skate wheel units can be easily moved by a single operator to reconfigure pathways on demand.

- Superior turning capability: The skate wheel design enables tighter turns than roller conveyors, allowing navigation around obstacles and optimization of limited floor space.

- Zero power requirement: Using gravity and minimal incline (typically 3-6 degrees), these spurs operate without electricity, reducing operational costs and eliminating the need for power connections at each dock.

- Adequate capacity: With 50 kg/m load capacity, these conveyors easily handle the vast majority of e-commerce parcels while maintaining excellent flow characteristics.

The connection points between powered spine and gravity spurs are designed for seamless transitions, with height adjustments ensuring smooth package handoffs without jams or bottlenecks.

Why this modular setup is perfect for handling fluctuating volumes per destination.

The hub-and-spoke approach offers several specific advantages for the variable nature of e-commerce fulfillment:

- Dynamic resource allocation: When volume shifts between shipping carriers or destinations, conveyor sections can be quickly reallocated from low-volume to high-volume areas, ensuring optimal resource distribution.

- Gradual investment: Rather than investing in permanent infrastructure for maximum capacity scenarios, operations can purchase only the conveyor sections needed for current volumes and add more incrementally as business grows.

- Fault tolerance: If any section requires maintenance, it can be quickly replaced with a spare while repairs are made, preventing operational downtime.

- Simple reconfiguration: As carrier relationships change or new shipping options are added, the entire outbound conveyor network can be reconfigured in hours rather than days or weeks.

- Storage efficiency: During non-peak periods, excess capacity can be collapsed and stored in minimal space, freeing valuable floor area for other operational needs.

This combination of powered reliability for consistent throughput and gravity flexibility for distribution creates the ideal parcel handling conveyor solution for today’s dynamic e-commerce requirements.

Handling Peak Season (e.g., Black Friday)

The true test of any e-commerce conveyor system comes during peak season, when volumes may increase by 300-500% over baseline. The modular Naili solution is specifically designed to scale seamlessly for these critical high-demand periods.

Easily add or re-route conveyor lines in minutes without special tools.

When peak season approaches, operations can rapidly expand capacity through several simple steps:

- Deploy stored conveyor sections: Collapsed conveyor sections kept in storage during normal operations can be rapidly deployed to create additional outbound lanes or extend existing ones.

- Reconfigure for capacity optimization: The layout can be adjusted to create shorter, more direct paths to high-volume carriers, reducing travel distance and increasing throughput.

- Add parallel processing lanes: For the highest-volume destinations, multiple gravity conveyor lanes can branch from the same powered section, allowing several operators to load trucks simultaneously.

- Implement temporary sorting branches: Additional sorting points can be created using gravity spurs to pre-stage specific destinations, carrier services, or priority levels.

- Create overflow capacity: When dock space is limited, extended conveyor lines can direct packages to temporary staging areas, maintaining sortation efficiency even when outbound shipping reaches capacity constraints.

Implementation Example: During normal operations, a facility might operate with one powered main line connected to 8 gravity spurs serving different carriers. For Black Friday, the system could expand to 16 gravity spurs by adding stored sections, with high-volume destinations receiving multiple dedicated lines to prevent bottlenecks.

The key advantage of the flexible logistics solutions approach is that these adjustments require:

- No specialized technicians

- No complex tools or equipment

- No production downtime for installation

- No permanent infrastructure changes

- No electrical work or permits

This adaptability ensures that operations can scale up precisely when needed without overinvesting in permanent capacity that sits idle during normal periods.

What about Returns? Using a reversible powered line for inbound processing.

Returns processing represents a growing challenge for e-commerce operations, with some sectors seeing return rates of 30% or higher. The same modular conveyor system that optimizes outbound shipments can be leveraged for efficient returns handling with minimal reconfiguration.

Bidirectional Capability

Naili’s powered roller conveyors feature bidirectional operation, allowing the same infrastructure to support both outbound and inbound flows:

- Morning configuration: Powered lines run forward to distribute outbound parcels from central sorting to shipping docks

- Afternoon configuration: Selected lines run in reverse to channel returns from receiving areas to processing stations

- Split operation: During peak returns periods (like post-holiday), some lines can be dedicated to returns while others continue outbound operations

Creating a Returns Processing Loop

For operations with significant returns volume, a dedicated processing configuration might include:

- Inbound receiving line: A powered roller conveyor transporting packages from receiving to initial inspection

- Processing stations: Gravity spurs branching off the main line to individual returns processing stations

- Disposition paths: After processing, additional gravity conveyors directing items to appropriate destinations:

- Resale inventory returns to stock

- Damaged items to evaluation/disposal

- Refurbishment items to repair stations

- Reboxing items to packaging

This configuration maximizes labor efficiency by bringing returns to specialized processing stations rather than requiring workers to transport items throughout the facility manually.

Temporary Returns Handling

For operations with seasonal returns surges, the modular nature of the system allows for temporary returns processing setups:

- Sections normally used for outbound shipping can be quickly reconfigured

- Temporary processing stations can be established in unused dock doors or floor space

- The entire returns operation can be scaled up or down based on actual volume

By utilizing the same equipment for both outbound shipment and returns processing, e-commerce operations can maximize their investment in conveyor infrastructure while maintaining the flexibility to adapt to changing business requirements.

Build an Agile, Scalable Conveyor System for E-commerce Success

The rapidly evolving landscape of e-commerce fulfillment demands conveyor solutions that prioritize adaptability without sacrificing performance. The combination of Naili’s powered roller conveyor main lines with flexible gravity skate wheel conveyor spurs creates precisely this balance—offering reliable throughput where needed and dynamic reconfigurability where beneficial.

This approach delivers several crucial advantages for modern sorting line extension needs:

- Investment protection: As your business evolves, your conveyor system evolves with it rather than requiring replacement

- Space optimization: Conveyors can be configured to work within your available space rather than dictating facility layout

- Capacity matching: Conveyor resources can be allocated precisely where needed, when needed

- Operational resilience: Quick reconfiguration capabilities allow rapid response to disruptions or opportunities

- Growth accommodation: The system can start small and expand incrementally as your business scales

In the competitive e-commerce landscape, operational agility often determines success. Those who can quickly adapt to changing consumer preferences, seasonal variations, and emerging market opportunities gain significant advantages over competitors with rigid infrastructure.

By implementing a modular conveyor strategy built around compatible Naili components, e-commerce fulfillment operations position themselves to meet today’s challenges while remaining ready for tomorrow’s opportunities—creating a foundation for sustainable growth and customer satisfaction.

Frequently Asked Questions

What is the typical ROI timeframe for implementing a modular conveyor system in e-commerce operations?

Most operations implementing the hub-and-spoke conveyor approach see ROI within 6-12 months through labor savings alone. The flexibility to adapt to seasonal peaks without additional staffing creates substantial cost advantages, with many facilities reporting 30-40% reduction in manual material handling labor requirements and significant improvements in fulfillment accuracy.

How quickly can staff learn to reconfigure these conveyor systems?

Basic conveyor reconfiguration techniques can be taught in a single training session lasting 1-2 hours. Most warehouse staff become proficient after 2-3 supervised reconfigurations. The systems require no special tools or technical knowledge, making them accessible to all staff members. Many operations create simple configuration templates for common scenarios to further streamline the process.

What maintenance is required for these conveyor systems?

Powered roller conveyors require monthly maintenance checks of drive belts, bearings, and electrical components. Gravity skate wheel conveyors need minimal maintenance—primarily quarterly checks of wheel bearings and frame connections. Both systems are designed for simple parts replacement when needed, with most maintenance tasks requiring only basic tools and skills.

Can these conveyor systems integrate with existing automation in my facility?

Yes, Naili’s conveyor systems are designed to connect easily with existing infrastructure. The adjustable height legs (450-1500mm range) allow them to match existing conveyor heights for smooth transitions. The powered sections can be synchronized with upstream systems through basic controls, while the gravity sections provide natural buffer zones between automated and manual processes.

What package sizes and weights can these conveyors handle?

The powered roller conveyors handle packages up to 100 kg/m with the multi-wedge belt system, while gravity skate wheel conveyors support up to 50 kg/m. For size, both systems work best with packages that have stable, flat bottoms. The modular design accommodates a wide range of package dimensions, though very small items (under 15cm in any dimension) may require special handling considerations.

Table of Contents

Recent Posts

Discover effective solutions for conveyor system integration between fixed sorters and loading docks. Bridge the automation gap with flexible, mobile conveyor systems for seamless logistics.

Master seasonal warehouse solutions with our peak season logistics guide. Learn how to expand loading capacity, manage high volumes, and implement flexible systems when you need them most.

Discover the most efficient frozen goods conveyor system for loading refrigerated trucks while maintaining cold chain integrity at your cold storage warehouse.

Optimize your wholesale club logistics with heavy-duty roller conveyor systems designed for bulk goods handling. Improve efficiency in Costco style warehouses with our solutions.

Optimize tire handling in automotive logistics with specialized conveyor for tires that provides superior grip and controlled movement, minimizing manual handling and increasing efficiency.