Loading Unloading Conveyors Manufacturer

Home > Product

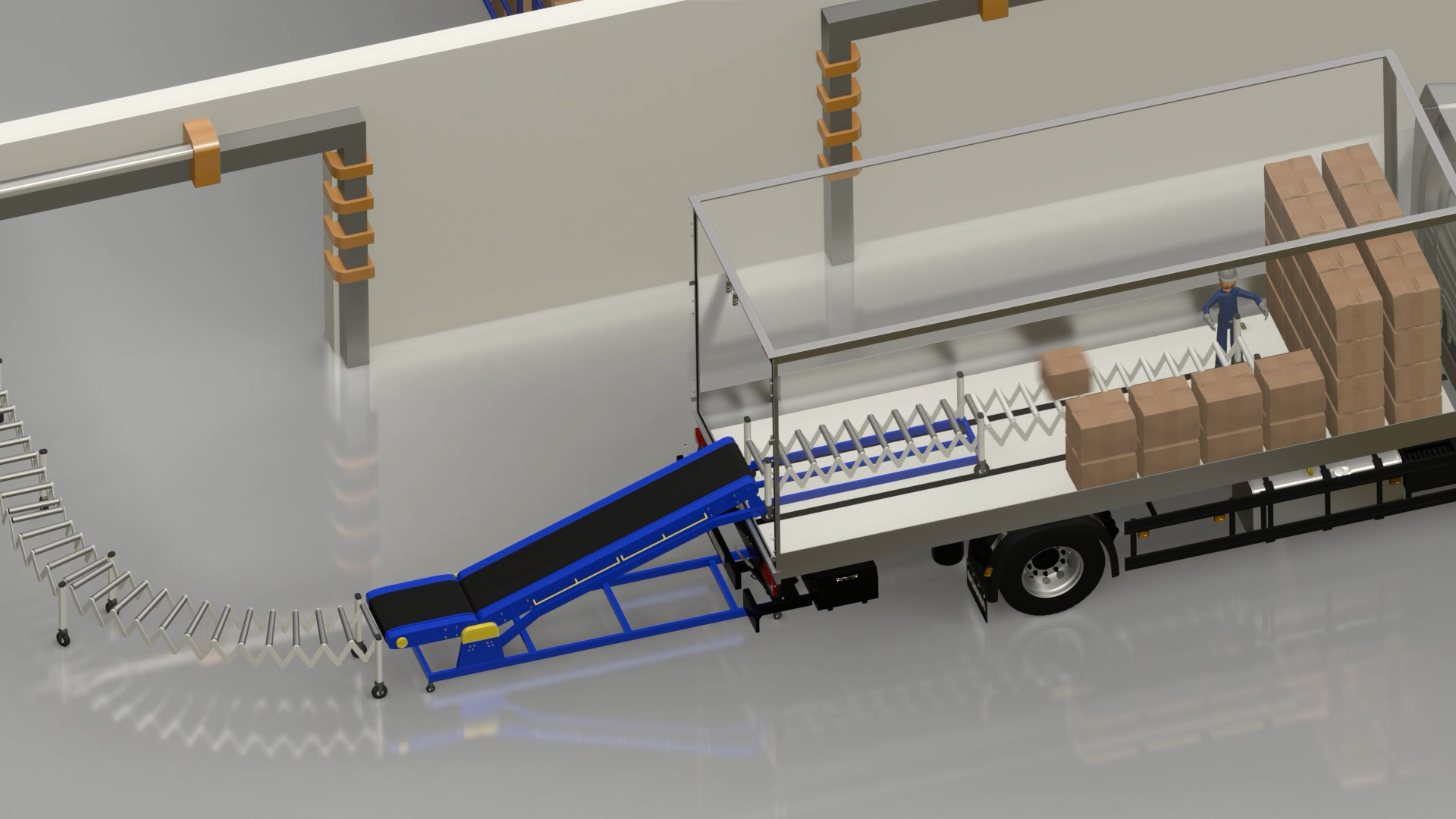

Enhance efficiency with Naili Conveyor’s advanced loading and unloading conveyors. Designed for warehouses, logistics hubs, and manufacturing facilities, our conveyors streamline material handling, reduce labor costs, and improve workflow. As a trusted manufacturer, we deliver durable, high-performance solutions tailored to your needs. Contact us for customized options.

Telescopic Conveyor

Discover premium telescopic conveyor solutions from a leading telescopic conveyor manufacturer. Our extendable systems deliver efficient loading/unloading for all logistics needs.

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 6000 | 16000 | 22000 |

| 7000 | 17000 | 24000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 5000 | 9000 | 14000 |

| 6000 | 12000 | 18000 |

| 7000 | 14000 | 21000 |

| 8000 | 17000 | 25000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 4000 | 5000 | 9000 |

| 5000 | 7000 | 12000 |

| 6000 | 8000 | 14000 |

| 6000 | 8500 | 14500 |

| 7000 | 9000 | 16000 |

| 7000 | 9500 | 16500 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 3000 | 2000 | 5000 |

| 4000 | 3000 | 7000 |

| 5000 | 4000 | 9000 |

| 6000 | 5000 | 11000 |

| 7000 | 6000 | 13000 |

Flat-bottomed Goods

Bagged Goods

Powered Rubber Roller Conveyor

Watch heavy bagged materials glide smoothly along production lines without slipping, sliding, or jamming—rubber roller conveyors make this reliable transport possible through specialized grip technology.

560 mm

1100 mm

120 kg/m

Flat-bottomed Goods

Bagged Goods

Powered Roller Conveyor

525 mm

1500 mm

80 kg/m

Flat-bottomed Goods

700 mm

2000 mm

100 kg/m

Flat-bottomed Goods

1050 mm

3000 mm

80 kg/m

Flat-bottomed Goods

Hydraulic Conveyor

Watch packages travel smoothly from ground level directly into truck beds or upper warehouse levels—hydraulic conveyors make this vertical journey possible through advanced lifting technology.

7900 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

7000 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

5400 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

3700 mm

50 kg/m

Flat-bottomed Goods

Bagged Goods

Gravity Skate Wheel Conveyor

Gravity skate wheel conveyors harness natural physics for moving goods effortlessly from trucks toward processing areas. Their elegantly simple design—wheels mounted between rails—creates nearly frictionless pathways where packages travel using only gravity’s gentle pull.

420 mm

2100 mm

50 kg/m

Flat-bottomed Goods

Gravity Roller Conveyor

Discover premium gravity roller conveyor solutions from a leading roller conveyor manufacturer. Our wide range of gravity & powered roller conveyor systems deliver exceptional efficiency for all logistics needs.

525 mm

1500 mm

50 kg/m

Flat-bottomed Goods

Bagged Goods

485 mm

1700 mm

50 kg/m

Flat-bottomed Goods

Bagged Goods

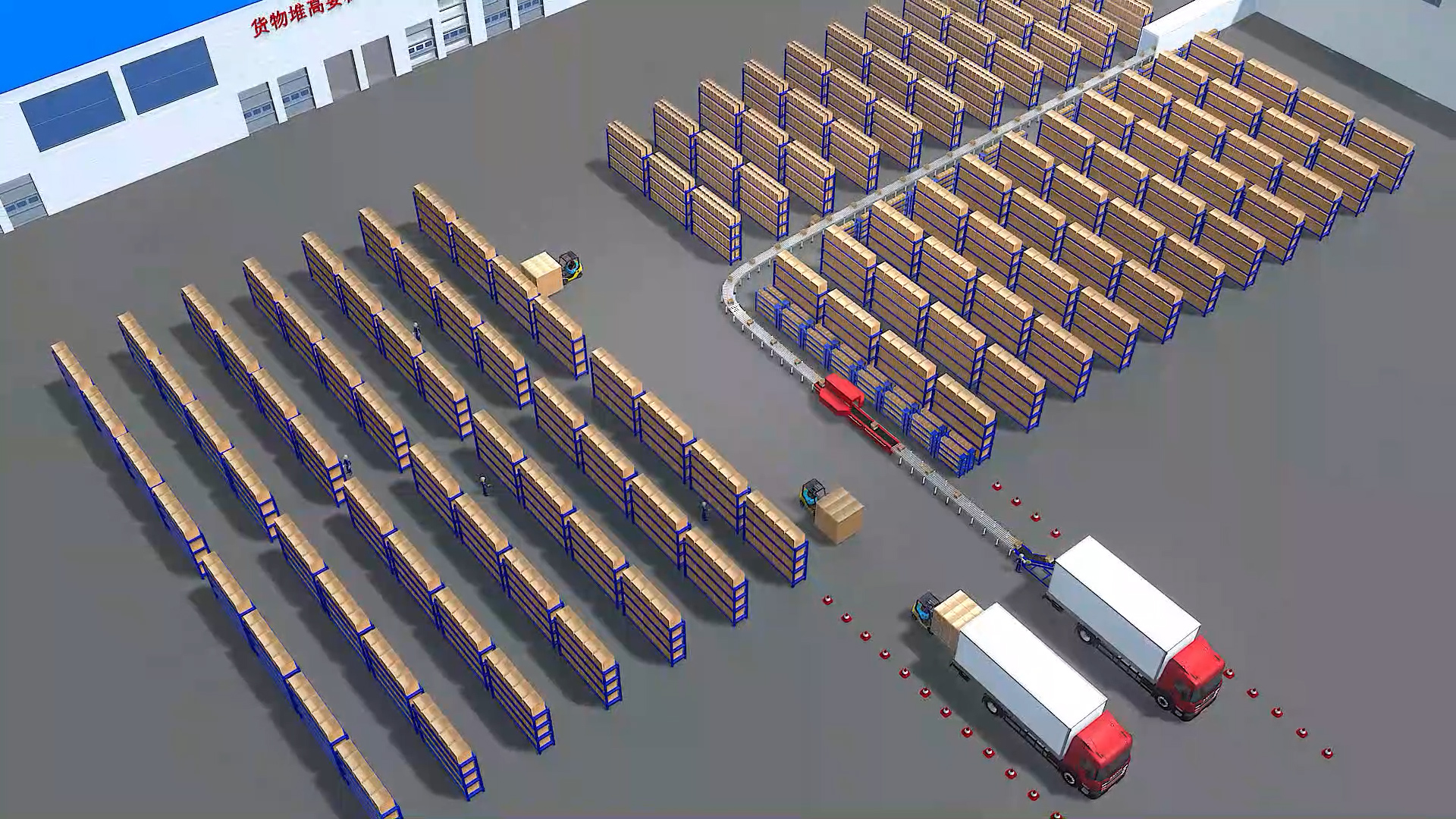

Imagine a logistics facility where every second matters. Workers manually carrying boxes between trucks and warehouses, with time running out and efficiency dropping. This isn’t just a hypothetical scenario—it’s a reality many businesses face every day during loading and unloading operations.

The right loading&unloading conveyor can transform this situation completely. We’ve seen how facilities improve when they implement efficient material transfer systems. When packages move smoothly from truck to warehouse or warehouse to truck, your team can focus on value-added activities rather than manual labor.

Conveyors are essential tools in modern logistics. They optimize the flow of goods during critical loading and unloading operations, reduce manual handling, and increase overall efficiency. Naili Conveyor offers a wide range of flexible loading and unloading conveyor systems designed to streamline these crucial transfer points. From handling packages to moving medium-sized items between trucks and warehouses, our products are engineered for flexibility and reliable performance.

Efficiency in loading and unloading is about maximizing throughput while minimizing effort. These systems cut operation times, increase productivity, and adapt to various spaces. Whether you’re loading delivery vehicles or unloading incoming shipments, Naili’s flexible loading&unloading conveyors mean improved operational performance.

Key Takeaways

- Flexible conveyor systems increase productivity in logistics environments.

- Modern foldable and expandable conveyor designs save space when not in use.

- Improved workflow reduces manual handling and increases throughput during loading/unloading.

- Adaptable solutions fit various vehicle types and facility configurations.

- Investing in flexible equipment strengthens competitiveness in logistics operations.

Understanding Flexible Loading&Unloading Conveyor Systems

Modern logistics operations depend on adaptable conveyor systems to move materials efficiently between vehicles and warehouses. The evolution of loading and unloading equipment has trended toward flexibility and mobility rather than fixed installations.

The Evolution of Flexible Material Handling Equipment

Traditional loading operations relied on manual labor or fixed infrastructure. Today’s operations benefit from highly adaptable conveyor systems that can be repositioned, expanded, or collapsed as needed. Naili’s flexible conveyors represent this modern approach to material handling.

Key Components of Flexible Conveyor Systems

- Expandable/collapsible frames that adjust to required lengths

- Adjustable height mechanisms for various vehicle types

- Locking casters for mobility and stability when positioned

- Lightweight yet durable construction for easy repositioning

How Flexible Loading&Unloading Conveyors Transform Logistics Operations

“Adaptable conveyor systems reduce loading and unloading times by up to 30% compared to manual methods,” states a 2023 industry report. These flexible setups allow businesses to handle shipments more efficiently without fixed infrastructure investments.

These systems also make excellent use of available space. When not in use, they can be collapsed and stored, freeing up valuable floor space. Companies across the logistics sector use this technology to improve operational efficiency without permanent modifications to their facilities.

The Practical Role of Flexible Conveyors in Today’s Logistics Chain

Flexible loading&unloading conveyor solutions address key challenges in modern logistics operations. They make transferring materials between vehicles and storage more efficient, reducing manual handling and associated labor costs.

These systems help address workforce challenges by multiplying the productivity of available staff. This allows teams to process more shipments with the same headcount. For example, logistics centers use expandable conveyor systems to quickly adapt to different vehicle sizes and load types. Here’s how they deliver practical benefits:

Benefit | Description |

Adaptability | Flexible designs accommodate various truck heights and loading configurations. |

Space Utilization | Collapsible systems can be stored when not in use, maximizing available space. |

Deployment Speed | Quick setup and repositioning without tools or specialized training. |

Flexibility is essential in modern logistics. During busy seasons, shipping volumes can fluctuate dramatically. Naili’s expandable conveyors help operations quickly scale their loading capacity without permanent infrastructure changes. “Investing in flexible conveyor systems provides immediate operational improvements while maintaining future adaptability,” a 2023 logistics report notes.

Flexible conveyor solutions also enhance business resilience. When loading requirements change, companies with these adaptable systems can quickly reconfigure their operations. By implementing flexible loading&unloading solutions, companies maintain operational agility while improving efficiency.

Types of Flexible Loading&Unloading Conveyors for Different Applications

Choosing the right flexible conveyor type is key for efficient transfer operations. Each system is designed to address specific loading and unloading scenarios. Naili Conveyor offers several adaptable options for various logistics applications.

Gravity Roller Conveyor: Simplified Vehicle-to-Warehouse Transfers

Naili’s gravity roller conveyors offer an economical and reliable option for moving goods from vehicles to warehouses. These flexible systems use the force of gravity to move items along the rollers, making them ideal for lighter materials. The key advantage is their ability to extend directly into vehicles for efficient unloading without fixed infrastructure. Their straightforward design requires no power source, minimizing operational costs while maximizing portability.

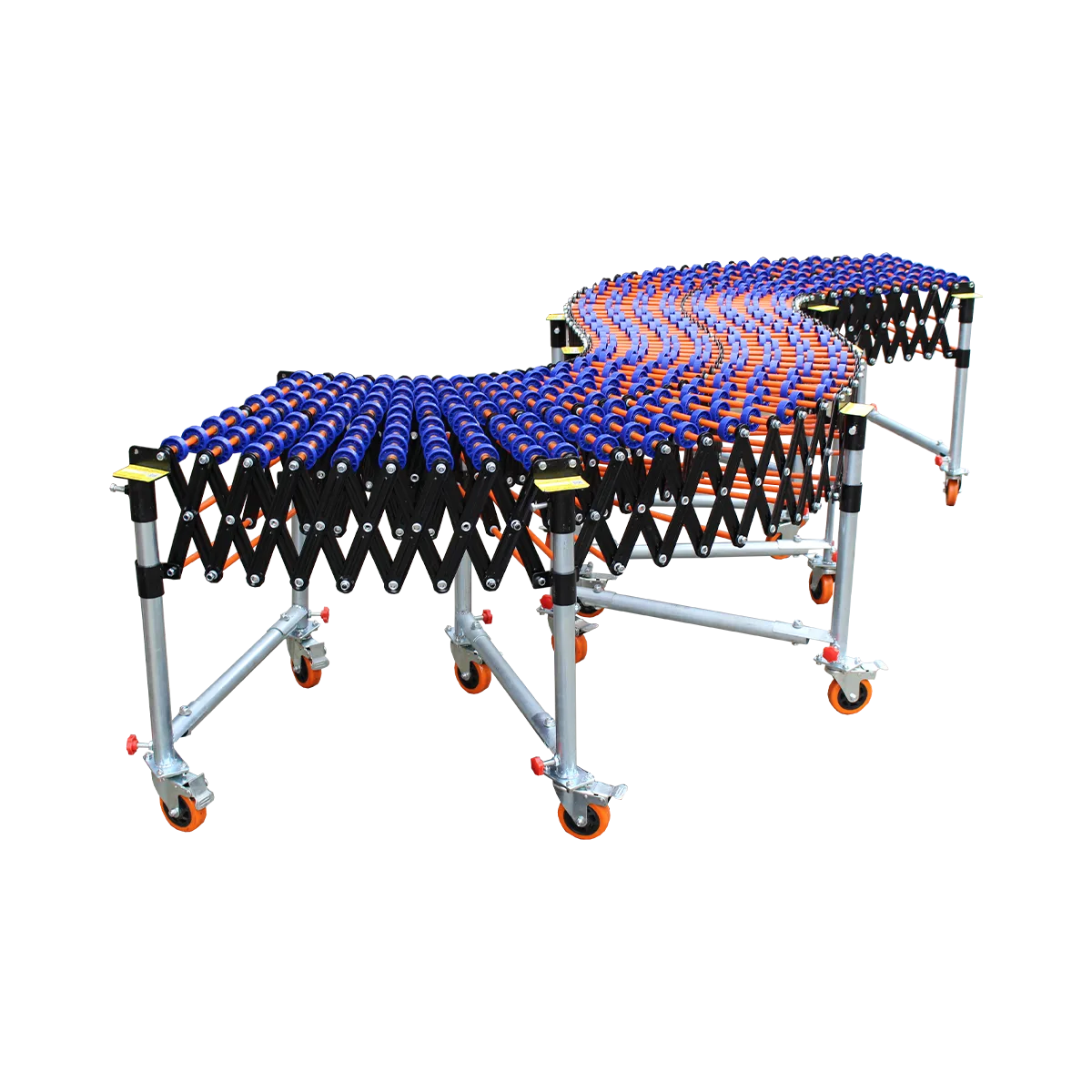

Expandable Roller Conveyor: Adaptable Length for Various Loading Scenarios

Expandable roller conveyors provide the ultimate flexibility in loading operations. These systems can compress to compact storage dimensions but extend to several times their collapsed length when needed. This expandable design allows a single unit to serve multiple loading bays or accommodate various vehicle depths. When not needed, they occupy minimal space, making them perfect for facilities where floor space is valuable.

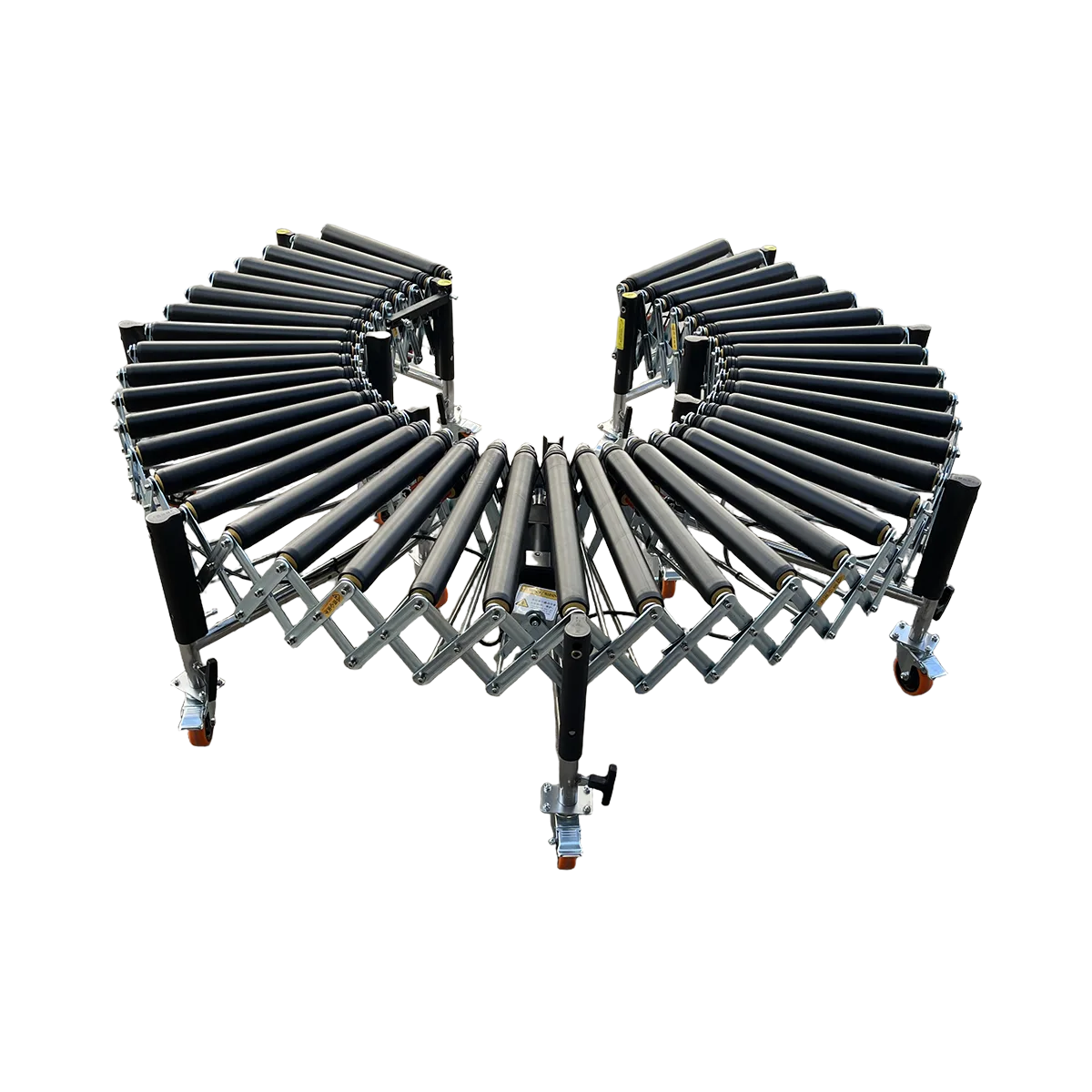

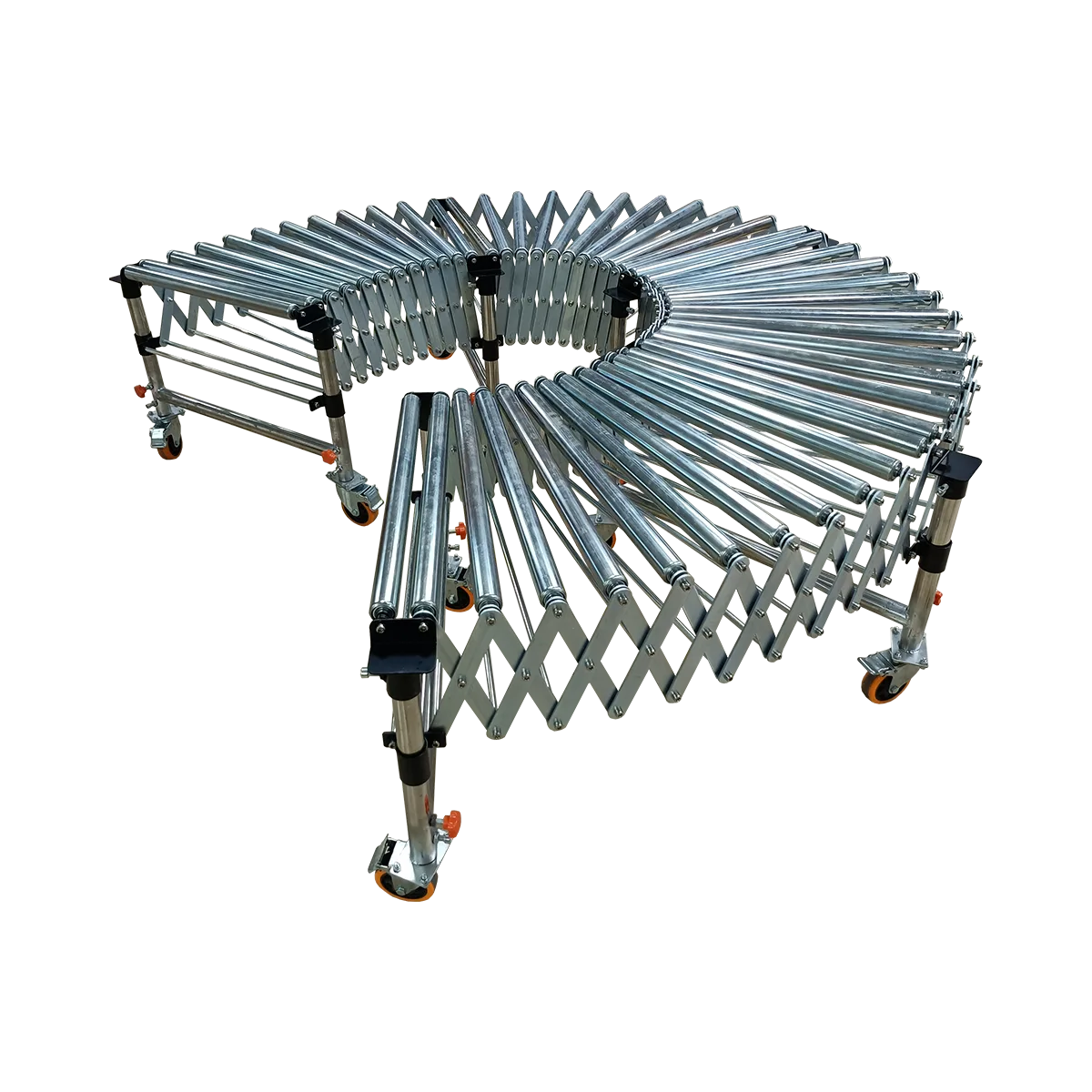

Flexible Curve Conveyor: Navigating Non-Linear Transfer Paths

Flexible curve conveyors solve the challenge of non-linear loading paths. These adaptable systems can form curves and bends, allowing materials to flow around obstacles or change direction between vehicle and storage areas. This flexibility is particularly valuable in facilities with limited space or awkward layouts. The adjustable configuration ensures goods can follow the most efficient path rather than requiring facility modifications.

Height-Adjustable Conveyor: Matching Various Vehicle Bed Heights

Naili’s height-adjustable conveyors address the challenge of varying vehicle bed heights. With hydraulic or manual adjustment mechanisms, these systems can align perfectly with everything from small delivery vans to full-sized trucks. This versatility eliminates the need for multiple dedicated systems for different vehicle types, providing a cost-effective solution for mixed fleets.

Folding Portable Conveyor: Storage Efficiency When Not In Use

Folding portable conveyors prioritize space efficiency and mobility. These lightweight systems can be quickly deployed when needed and folded into compact forms for storage. Their portability makes them ideal for operations with multiple loading areas or facilities that handle intermittent shipments. Easy-rolling casters allow a single operator to position these conveyors wherever they’re needed, then store them away when the task is complete.

Telescoping Conveyor: Reaching Deep Into Vehicles and Containers

Telescoping conveyors excel at reaching deep into vehicles without requiring staff to enter the cargo area. These extending systems can reach the far end of delivery trucks or containers, then retract when not needed. This reach capability significantly reduces unloading time while minimizing physical strain on workers. The telescoping design provides maximum functional length while maintaining manageable storage dimensions.

Efficiency Benefits of Implementing Flexible Conveyor Systems

Flexible loading&unloading conveyor systems transform how goods move between vehicles and warehouses. They make transfer operations smoother and increase throughput without permanent infrastructure. By providing adaptable material handling capabilities, these systems reduce loading/unloading times while maintaining operational flexibility.

Studies show operations using flexible conveyor systems process shipments 25–35% faster than those relying on manual methods. This represents significant improvement in transfer efficiency.

- Quick deployment allows immediate response to incoming vehicles

- Adjustable configurations adapt to various package types and sizes

- Reduced manual handling allows staff reallocation to higher-value tasks

Metric | Manual Loading/Unloading | Flexible Conveyor |

Package Handling Rate | 300-400 items/hour | 800-1000 items/hour |

Staff Required | 2-3 workers per vehicle | 1-2 workers per vehicle |

Physical Strain | High repetitive motion risk | Significantly reduced handling |

These systems complement existing logistics workflows without requiring facility renovations or fixed equipment installation. Naili Conveyor clients typically see 30-40% improvement in loading/unloading productivity after implementing flexible systems.

Adaptable loading systems also optimize valuable floor space by storing compactly when not in use. This dual-purpose approach reduces the operational footprint while maintaining high transfer capacity during active periods. The result is operational savings in both labor hours and facility space, making flexible conveyors a practical choice for logistics efficiency.

Mobile Conveyor Options for Dynamic Loading Operations

Modern logistics operations demand equipment that adapts to changing requirements. Mobile conveyors provide this flexibility, allowing for quick deployment and reconfiguration. They’re ideal for operations serving multiple loading areas or handling various vehicle types throughout the day.

Portable Loading Conveyors for Adaptable Logistics Operations

Naili’s portable models can be quickly positioned wherever needed in the facility. Their lightweight yet sturdy design allows for single-person repositioning. These are perfect for operations with multiple receiving doors or fluctuating shipping schedules, maximizing equipment utilization across the facility.

Adjustable Height and Angle Features

- Manual or powered height adjustment to match various vehicle bed elevations

- Incline adjustment capabilities for optimal package flow and ergonomics

- Quick-set locking mechanisms for stability during active loading operations

Mobility and Storage Considerations

Naili’s loading conveyors feature non-marking casters for easy movement across facility floors. Compact folding designs allow storage in minimal space when not needed. Models with integrated handles and lightweight construction ensure easy repositioning by a single operator. Many designs include braking systems to secure the conveyor during active use.

Practical Applications Across Different Loading Scenarios

Naili Conveyor systems address key loading and unloading challenges across various logistics operations. Their flexibility makes them suitable for diverse transfer scenarios without permanent installation. From e-commerce fulfillment to retail distribution, they make material transfer operations more efficient and adaptable.

- Parcel Delivery Operations: Quickly load outgoing shipments from sorting area to delivery vehicles

- E-commerce Fulfillment: Transfer incoming inventory from suppliers to receiving areas

- Retail Distribution: Handle carton unloading for store replenishment operations

- Manufacturing Logistics: Move finished goods from production area to outbound shipping

- Third-Party Logistics: Adapt to various client shipping and receiving requirements

“Flexible loading&unloading conveyor solutions provide immediate operational improvements without facility modifications.” — Naili Manufacturing

Naili’s loading&unloading conveyor systems adapt to the specific requirements of each operation. Their portable nature makes them ideal for growing businesses or facilities with changing needs. Partnering with suppliers who understand logistics flexibility helps your business maintain adaptable transfer operations.

How to Select the Right Flexible Loading&Unloading Conveyor

Choosing the right flexible conveyor system starts with understanding your specific transfer operations. Analyze your typical package sizes and volumes alongside vehicle types. Consider your facility layout and available storage space for equipment when not in use. This ensures the system matches your daily operational requirements while maintaining future adaptability.

Assess Your Loading/Unloading Requirements

- Determine typical package dimensions and weights to select appropriate conveyor capacity

- Consider your vehicle mix to ensure height adjustment capabilities are sufficient

- Analyze peak volume periods to size system throughput appropriately

Capacity and Throughput Requirements

Calculate your hourly transfer volume during normal and peak periods. Select conveyor width and roller spacing appropriate for your typical package sizes. Ensure your selected system can handle future growth without replacement.

Space and Storage Considerations

Measure your available operational and storage space. Select conveyor designs that balance extended working length with compact storage dimensions. Consider systems with folding or nesting capabilities for facilities with limited storage.

Budget and Value Analysis

“A 2023 logistics analysis shows most operations recover flexible conveyor investments within 4-8 months through labor efficiency alone.”

- Compare system cost against projected labor savings and throughput improvements

- Consider the value of operational flexibility across changing business needs

- Evaluate durability and maintenance requirements when comparing options

Consult with Naili’s logistics specialists to evaluate your specific transfer operations. They can recommend flexible solutions that maximize efficiency while maintaining the adaptability your business needs as volumes fluctuate.

Integration With Existing Logistics Operations

Today’s flexible loading and unloading conveyors must complement your existing operations without disruption. Naili’s systems are designed to integrate seamlessly into various logistics workflows without requiring facility modifications or fixed infrastructure.

Successful implementation depends on selecting the right conveyor configurations and training staff on optimal positioning and use. This creates efficient transfer operations without expensive facility renovations.

- Receiving workflows benefit from expandable systems that reach directly into delivery vehicles

- Shipping operations can use height-adjustable models to match various outbound vehicle types

- Cross-docking benefits from mobile conveyors that can quickly reposition between inbound and outbound areas

Naili’s flexible systems require minimal integration effort compared to fixed conveyor installations. Their standalone operation means no electrical or control system modifications to your facility.

Even operations with limited space can benefit from Naili’s collapsible designs. Systems can be deployed during active loading periods and stored compactly when not needed. Look for solutions with quick setup features to minimize transition time between storage and operational states.

When selecting flexible loading/unloading conveyors, consider how they’ll complement your current operational flow. Also, evaluate how their adaptability will accommodate future changes in your logistics requirements.

Maintenance Considerations for Flexible Conveyor Systems

Keeping flexible conveyor systems in optimal condition requires different approaches than fixed installations. The primary focus is maintaining mobility components and ensuring reliable deployment. Here’s how to maintain peak performance:

Routine Maintenance Requirements

Implement regular checks of moving components to ensure smooth operation. Weekly inspections should include caster condition, height adjustment mechanisms, and roller freedom of movement. Monthly, verify frame locking mechanisms and extension systems function properly.

Quarterly, lubricate all moving parts according to manufacturer specifications. Use appropriate lubricants for components that contact packages to prevent contamination.

Common Issues and Simple Solutions

- Difficult extension/retraction: Clean and lubricate sliding frame components

- Caster movement problems: Remove debris from wheels and check locking mechanisms

- Roller resistance: Verify bearings are clean and properly lubricated

Preserving System Longevity and Performance

Store systems in clean, dry areas when not in use to prevent corrosion or contamination. Implement proper handling procedures to prevent frame damage during repositioning. Train operators on correct extension and height adjustment techniques.

Keep operation manuals accessible for reference during maintenance.

“Properly maintained flexible conveyor systems typically deliver 5+ years of reliable service with minimal parts replacement.”

Address any unusual noises or resistance immediately to prevent component failure. Follow manufacturer guidelines for periodic replacement of high-wear components. Always verify system stability before active loading operations begin.

Naili Conveyor: Quality and Flexibility You Can Trust

When selecting a loading&unloading conveyor system, choosing a manufacturer focused on flexible, adaptable designs is crucial. Naili Conveyor specializes in portable, expandable conveyor solutions ideal for dynamic logistics operations. Our products are engineered for quick deployment, easy mobility, and compact storage when not in use.

Naili Conveyor has established itself as a provider of practical logistics solutions with designs that address real-world loading and unloading challenges. Our engineering team develops systems that enhance efficiency without requiring permanent facility modifications.

Naili offers logistics operations:

- Adaptable designs for various vehicle types and package dimensions

- Durable construction that withstands frequent repositioning

- Easy-to-use adjustment mechanisms for quick deployment

- Space-efficient storage capabilities when not in active use

By choosing Naili Conveyor, you’re selecting a partner committed to improving your logistics efficiency through flexible material handling solutions that grow with your business needs.

Future Trends in Flexible Loading&Unloading Conveyor Technology

The world of adaptable conveyor systems continues to evolve. Logistics operations increasingly seek solutions that combine flexibility with enhanced functionality. New design approaches are making loading and unloading operations more efficient while maintaining the core benefits of mobility and adaptability.

These advancing systems are becoming even more versatile while requiring less effort to deploy and adjust.

- Lightweight composite materials: Stronger yet lighter frames that improve portability

- Quick-connect modular designs: Systems that combine to create custom configurations

- Improved ergonomics: Height adjustment systems that require less physical effort

- More compact storage profiles: Enhanced folding mechanisms for minimal storage footprint

- Integrated package handling aids: Flexible side guides and package stops that reduce product damage

By adopting these evolving technologies, logistics operations can further enhance their material handling capabilities. Upgrading to the latest flexible loading&unloading conveyor systems helps distribution centers maintain operational agility while improving throughput. Investing in adaptable solutions prepares companies for changing logistics requirements without fixed infrastructure limitations.

Conclusion: Enhancing Your Loading Operations with Flexible Conveyor Systems

Flexible loading&unloading conveyor systems are essential tools for modern logistics success. They combine operational efficiency with adaptability to changing requirements. Selecting systems that match your specific transfer needs ensures optimal performance without permanent facility modifications.

Naili Conveyor provides adaptable loading solutions for various logistics operations. Working with manufacturers who understand the importance of flexibility ensures your material handling equipment can evolve with your business.

By implementing the right flexible conveyor systems, you can transform your loading and unloading operations while maintaining future adaptability. Start by evaluating your current transfer processes and identifying opportunities for efficiency improvements. Investing in these adaptable systems helps your logistics operation enhance productivity while preserving operational flexibility.

FAQ

What types of flexible loading&unloading conveyors do you offer?

Naili offers expandable roller, flexible curve, height-adjustable, folding portable, telescoping, and gravity roller conveyors, each designed for specific loading and unloading applications.

Can your conveyors accommodate different vehicle types?

Yes, Naili Conveyor’s height-adjustable systems can align with various vehicle bed heights, from small vans to full-size trucks, without permanent infrastructure.

How quickly can I set up and reposition your conveyor systems?

Most Naili conveyors can be deployed or repositioned in less than 5 minutes by a single operator, with no tools required for standard adjustments.

Where can I store the conveyors when not in use?

Our folding and collapsible designs typically reduce to 1/3 or 1/4 of their extended length, allowing for efficient storage along walls or in unused corners of your facility.

What maintenance do flexible conveyors require?

Simple regular maintenance includes lubricating moving parts, cleaning roller surfaces, and inspecting casters – typically requiring less than 30 minutes per month per unit.

How long do your flexible conveyor systems typically last?

With proper maintenance and handling, Naili’s flexible conveyor systems provide 5-7 years of reliable service in typical logistics applications.

What makes Naili flexible conveyor systems different from competitors?

Naili focuses on practical designs that balance durability with easy mobility, creating systems that truly enhance logistics operations without sacrificing reliability or performance.