The Best Conveyor for Soft Packages and Bags: Introducing the Powered Rubber Roller Conveyor

Struggling with soft packages slipping on standard conveyors? Discover how a rubber roller conveyor provides the perfect grip and protection for bags and flexible packaging.

Related Products

- Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

Transporting soft-sided packages, polybags, and irregularly shaped items through a warehouse presents unique challenges that standard material handling equipment often fails to address. When packages sag between rollers or slip during transport, operations slow down and product damage increases. The rubber roller conveyor offers a specialized solution designed specifically for these problematic items. With its PVC-coated rollers providing superior grip and consistent contact with soft-bottomed packages, this non-slip conveyor ensures smooth transport even for the most challenging materials, making it an essential asset for modern logistics operations dealing with diverse packaging types.

The Unique Challenge of Transporting Soft and Irregular Items

Today’s supply chains handle an increasingly diverse range of packaging types. E-commerce returns arrive in polybags, agricultural products come in flexible sacks, and many consumer goods use soft packaging to reduce shipping weight and costs. These items share a common problem: they don’t behave predictably on standard conveyor systems.

Soft packages present several distinct challenges:

- They tend to sag between rollers, causing uneven movement

- They lack the rigid bottom surface needed for smooth transport

- They’re more susceptible to getting caught or jammed in the conveyor

- They often have irregular shapes that roll or shift during movement

- They may have slick outer surfaces that slip on standard metal rollers

These issues aren’t merely inconvenient—they can significantly impact operational efficiency, causing line stoppages, increasing manual handling requirements, and potentially damaging products.

Why Standard Roller Conveyors Can Fall Short for Soft Packages

Lack of Grip

Conventional conveyor systems use metal rollers that provide minimal friction. While this design works well for rigid cartons with flat bottoms, it creates problems for soft packaging:

- Polybags and plastic packaging tend to slip on metal surfaces

- Inconsistent movement speeds as packages slide and then catch

- Difficulties in maintaining proper spacing between items

- Unpredictable behavior on inclines where gravity assistance is needed

This slipping effect is especially problematic in high-speed operations where precise timing and consistent flow are essential.

Potential for Damage Between Rollers

The spacing between rollers on standard conveyors creates another issue:

- Soft packages sag between rollers, creating an uneven transport surface

- Sagging can cause products inside the packaging to shift or become damaged

- Edges of flexible packaging can catch in the gaps between rollers

- Irregular movement creates strain on packaging seams

- Increased risk of jams that require manual intervention

These problems multiply as package weight increases, with heavier items sagging more dramatically and causing more significant operational disruptions.

The Solution: Powered Rubber Roller Conveyors

The powered rubber roller conveyor provides an elegant solution to these challenges through a specialized design focused on the unique needs of soft packaging.

How the PVC Rubber Coating Makes a Difference

The defining feature of the rubber roller conveyor is its PVC-coated rollers, which transform how it interacts with packages:

- Enhanced Grip: The rubber surface creates significantly more friction than metal rollers, preventing slippage even with glossy packaging materials

- Gentle Handling: The slightly yielding surface absorbs minor impacts, protecting contents from damage

- Consistent Contact: The rubber coating helps the rollers maintain continuous contact with irregular package surfaces

- Reduced Noise: The rubber dampens the sound of packages moving across the conveyor, creating a quieter work environment

- Static Reduction: PVC coating helps reduce static buildup that can occur with certain packaging materials

The combination of these benefits creates a more reliable transport surface for challenging items that would otherwise require manual handling or specialized equipment.

Features and Specs of Naili’s Rubber Roller Conveyor

Naili’s Powered Rubber Roller Conveyor combines the specialized rubber roller design with robust engineering to create a versatile solution for soft package handling.

High Load Capacity

Despite its specialized nature, this conveyor doesn’t compromise on performance:

- Impressive 120 kg/m load capacity, exceeding many standard roller conveyors

- Sturdy construction with frame thickness ≥3.5mm using Q345 grade steel

- Support legs constructed of 30×30mm 201 stainless steel tubing

- Four height adjustment options to match your facility’s needs:450-680mm

- 550-820mm

- 750-1200mm

- 900-1500mm

Multi-Wedge Belt Drive for Powerful Performance

The power transmission system uses a multi-wedge belt design that offers several advantages:

- More efficient power transfer than standard O-ring belts

- Better durability under heavy loads

- Reduced maintenance requirements

- Each reducer motor (120W) powers a section of the conveyor

- Variable frequency drives available in 0.75/1.5/2.2 kW options to match system length

The drive system delivers adjustable speeds up to 40 m/min, allowing you to optimize throughput based on your specific operational needs.

Small Roller Gap for Smooth Transport

One of the most critical design elements is the close spacing between rollers:

- 57mm standard distance between rollers

- 10 rollers in the standard section, 9 in the extension section

- 54mm roller diameter with ≥1.5mm wall thickness

- PVC rubber coating on zinc-plated or 201 stainless steel roller bodies

This tight roller spacing virtually eliminates the sagging problem common with soft packages on standard conveyors, creating an almost continuous transport surface.

Flexible Design Features

The practical design includes:

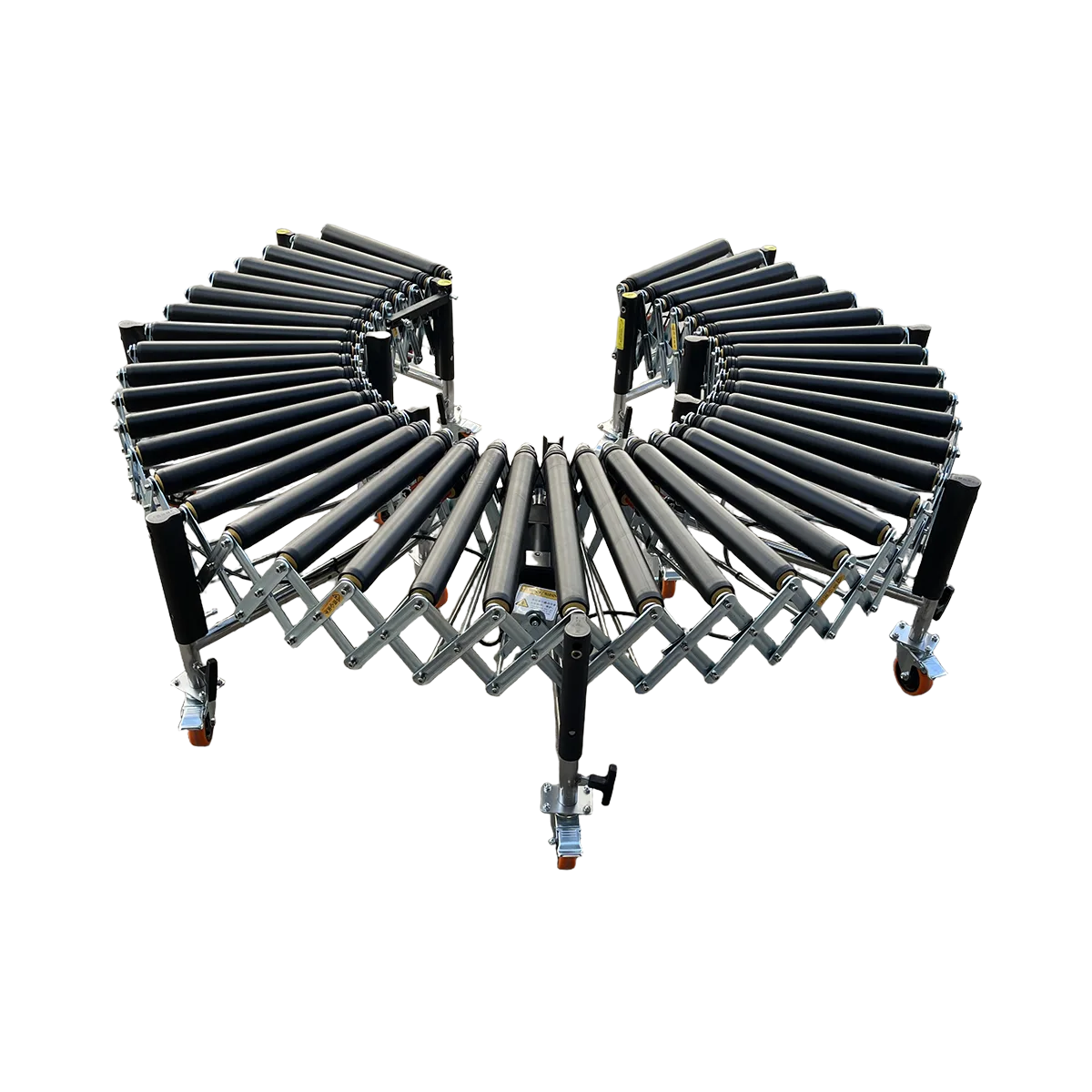

- Expandable sections: 560mm collapsed length extends to 1100mm (1:3 ratio)

- Available in multiple widths: 500/600/800mm to accommodate various package sizes

- Control panel with bidirectional operation, emergency stop, and speed control

- 4-inch casters with brakes for mobility when needed

- 12-month frame warranty and 6-month belt warranty

Ideal Applications

The powered rubber roller conveyor excels in several specific applications where soft packaging is common.

Mail and Postal Centers

Modern postal operations handle millions of polybags and padded mailers daily:

- E-commerce shipments in poly mailers

- Return packages in a variety of flexible packaging

- Magazines and catalogs in plastic wrapping

- Soft-sided express envelopes

- Irregular-shaped parcels

The rubber roller conveyor’s consistent grip and smooth transport significantly reduce jams and manual handling requirements in these high-volume environments.

Agriculture and Food Processing

Agricultural products present some of the most challenging transport scenarios:

- Bags of seed, grain, and animal feed

- Flexible packaging for processed foods

- Heavy sacks of fertilizer or soil amendments

- Mesh bags of produce

- Inconsistent sizes and weights

The high load capacity (120 kg/m) combined with the non-slip surface makes the rubber roller conveyor particularly valuable for heavier agricultural products like 50kg feed bags.

E-commerce Returns Processing

Return processing centers face unique challenges:

- Packages arrive in widely varying conditions and packaging types

- Original boxes are often replaced with polybags or irregular packaging

- Items may be improperly repackaged by customers

- High throughput requirements with minimal handling

- Need to direct packages to different processing stations

The versatility of the rubber roller conveyor makes it ideal for these unpredictable environments where package standardization is impossible.

Conclusion: Handle Any Package with Confidence

In today’s diverse logistics landscape, the ability to efficiently handle any packaging type is a competitive advantage. The powered rubber roller conveyor addresses the specific challenges of soft, flexible, and irregular packages that standard conveyor systems simply weren’t designed to handle.

By incorporating Naili’s rubber roller conveyor into your material handling system, you gain the versatility to process everything from rigid cartons to the most challenging soft packages with equal efficiency. This capability is increasingly valuable as e-commerce continues to reshape packaging norms and supply chain requirements.

Whether you’re outfitting a new facility or upgrading an existing one to handle a wider range of packaging types, the rubber roller conveyor provides a specialized solution that fills a critical gap in traditional telescopic conveyor systems. With its unique combination of grip, gentle handling, and robust performance, it ensures that no package—regardless of shape, rigidity, or surface—disrupts your operational flow.

Frequently Asked Questions

How does a rubber roller conveyor differ from a standard roller conveyor?

The key difference is the PVC rubber coating on the rollers, which provides superior grip for soft packages and prevents slipping. The rollers are also more closely spaced (57mm apart) to prevent sagging between rollers.

What is the maximum weight capacity of the rubber roller conveyor?

Naili’s Powered Rubber Roller Conveyor has a capacity of 120 kg/m, which is higher than many standard roller conveyors.

Can the rubber roller conveyor be integrated with other conveyor types?

Yes, it can be seamlessly integrated with other Naili conveyor systems to create a complete material handling solution. It works well as part of a larger system where certain sections specifically handle soft packages.

What maintenance is required for the rubber rollers?

Maintenance is relatively simple, involving regular cleaning of the rollers, checking the drive belt tension, and occasional inspection of the PVC coating for wear. The drive belts typically need replacement every 6-12 months depending on usage.

Is the speed adjustable on the rubber roller conveyor?

Yes, the conveyor features variable speed control through a frequency inverter, allowing adjustment up to 40 m/min to match your operational requirements.

Table of Contents

Recent Posts

Optimize hardware store logistics with the right building supply conveyor systems. Our guide to tool distribution systems enhances retail warehouse automation for efficient operations.

Optimize your medical supply logistics with efficient gravity conveyor systems. Learn how to safely handle healthcare products while improving your hospital supply chain operations.

Discover how a sports equipment conveyor system can streamline your athletic gear logistics. Flexible conveyor solutions for all shapes and sizes of sporting goods.