Gravity Skate Wheel Conveyor Manufacturer

Home > Skate Wheel Conveyor > Gravity Skate Wheel Conveyor

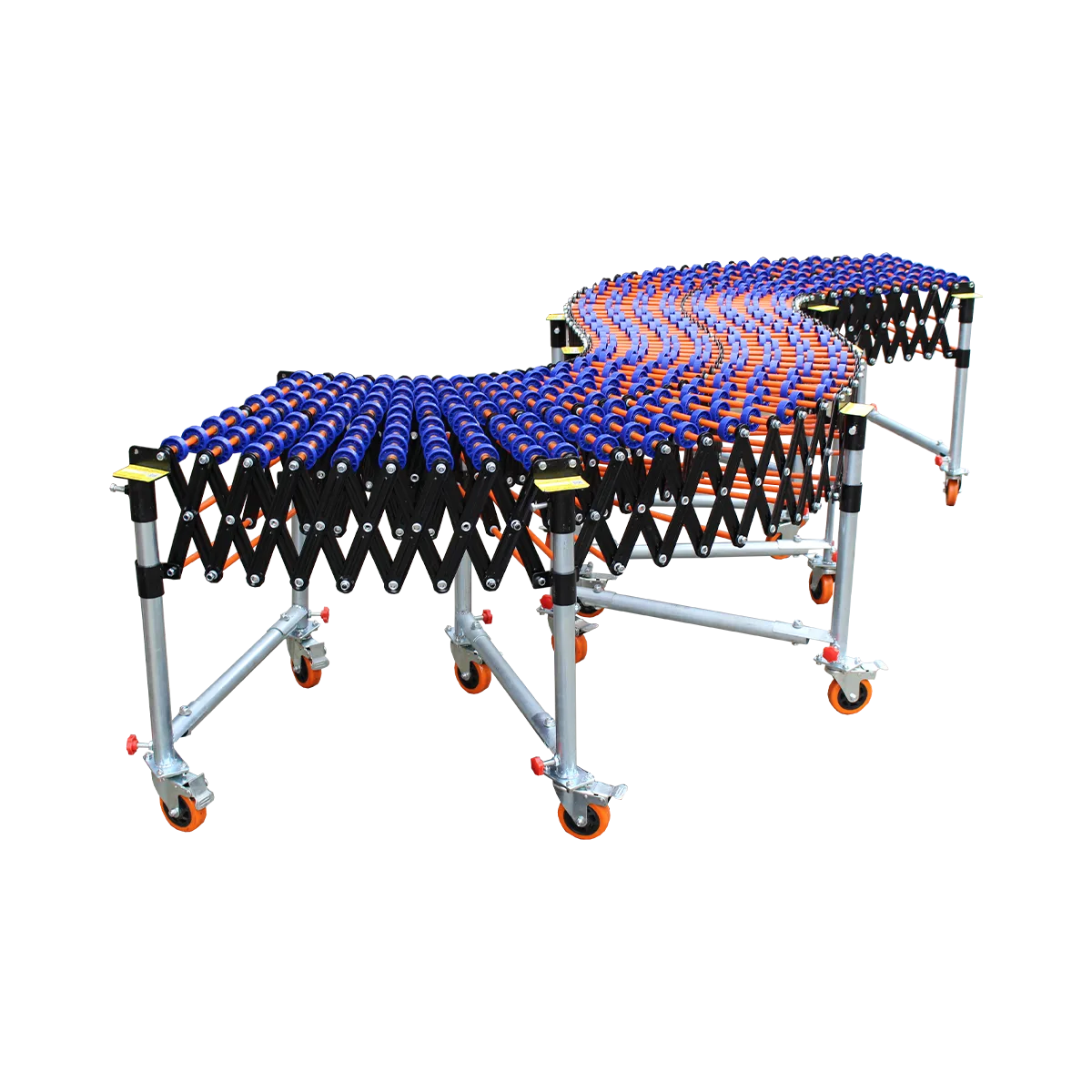

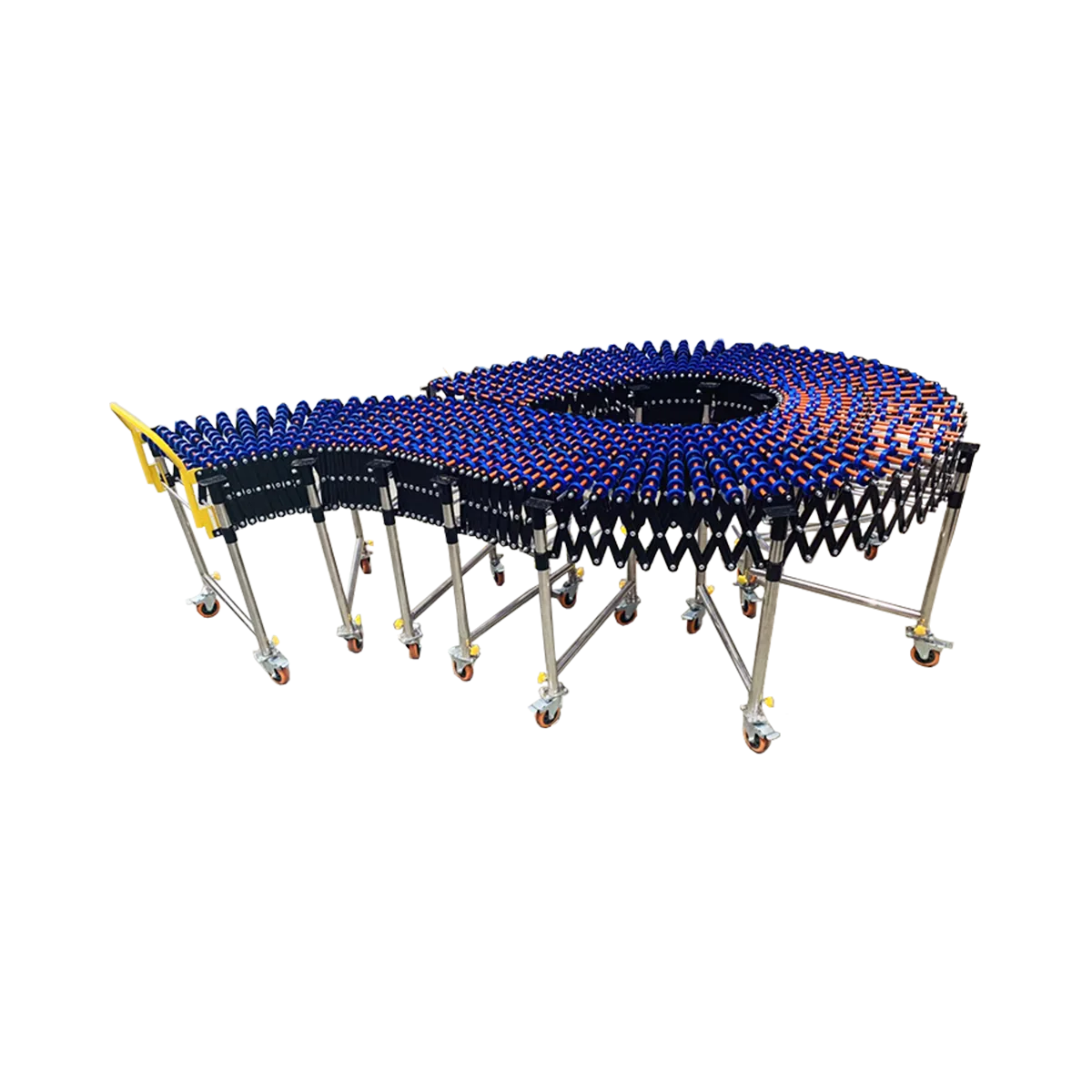

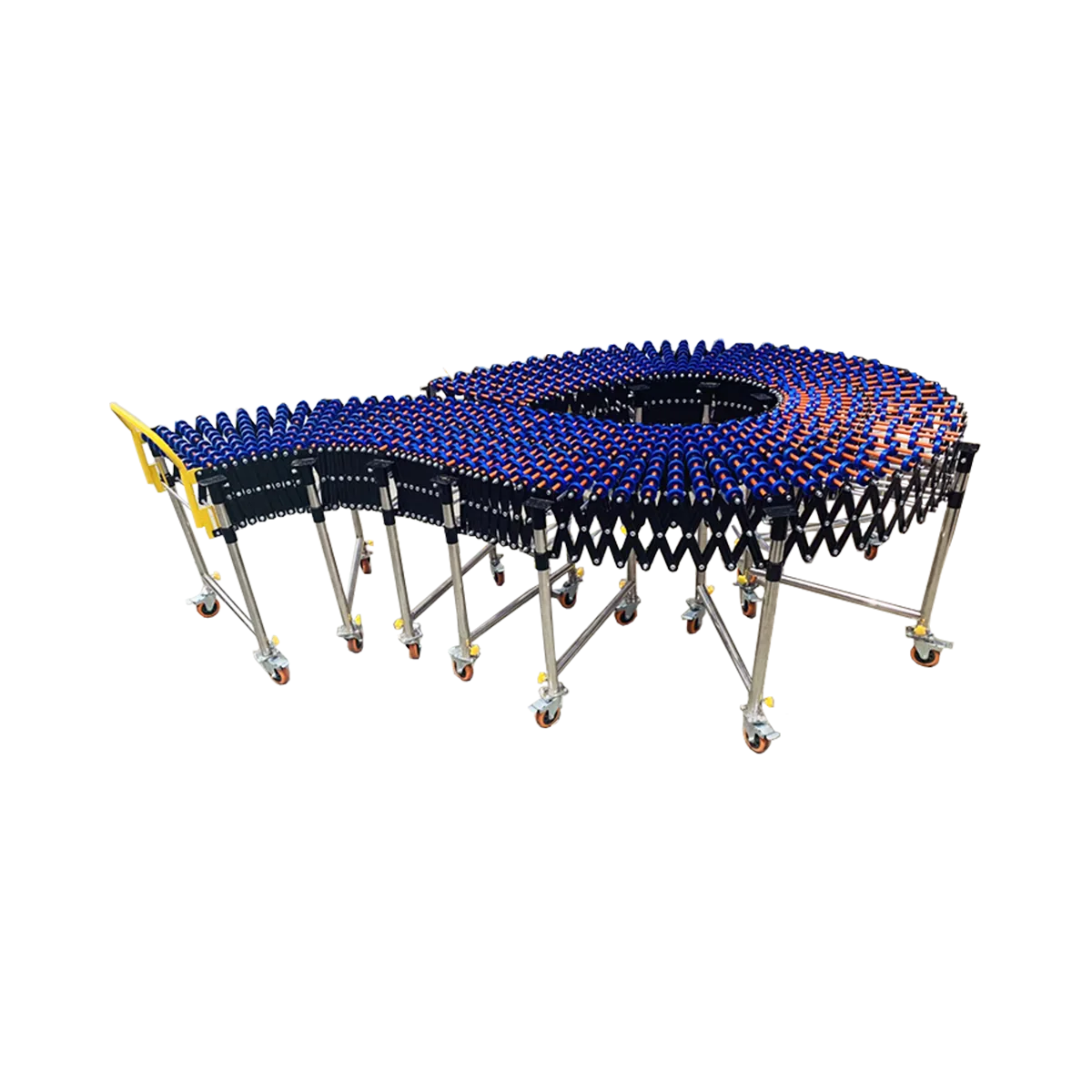

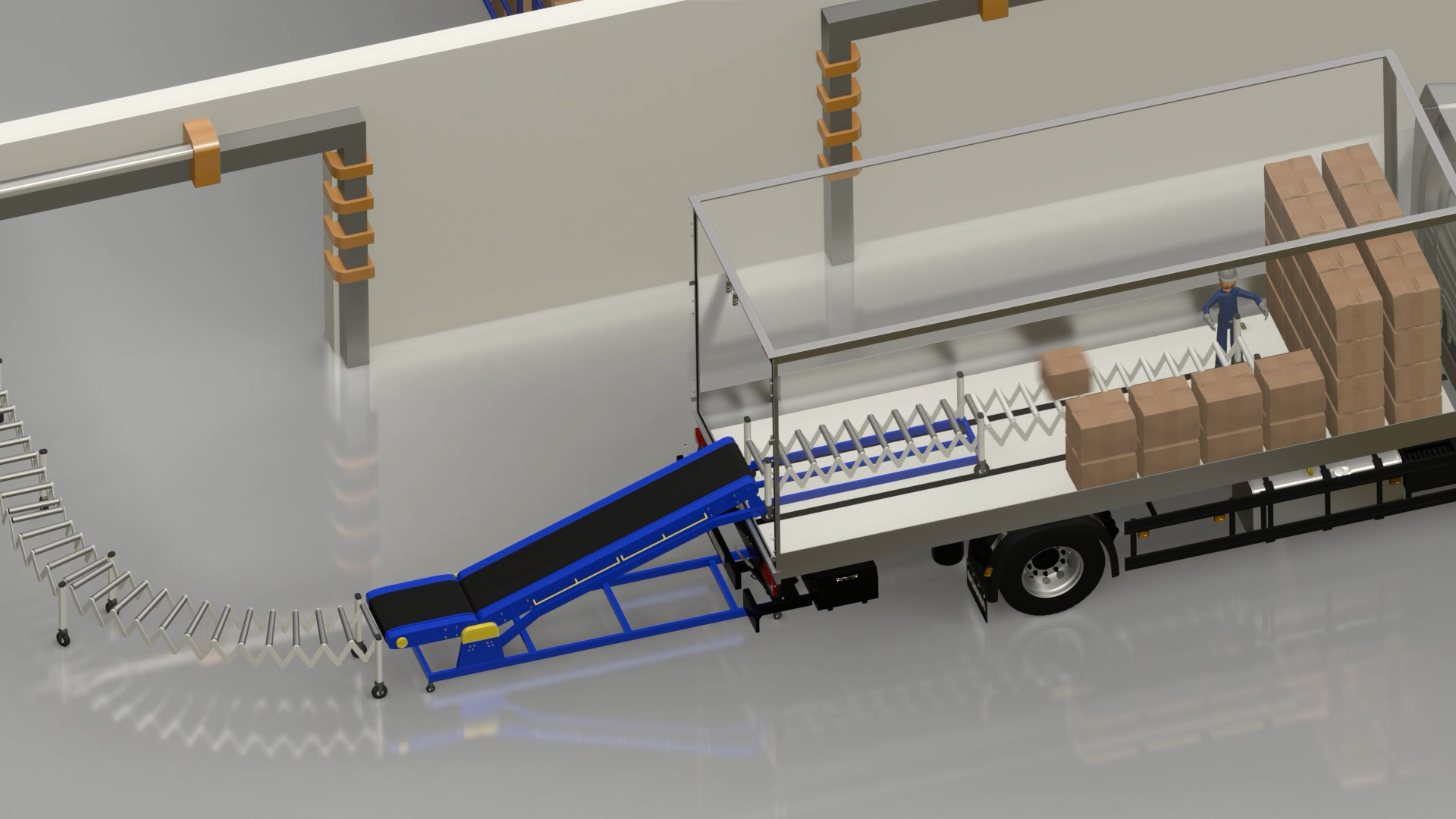

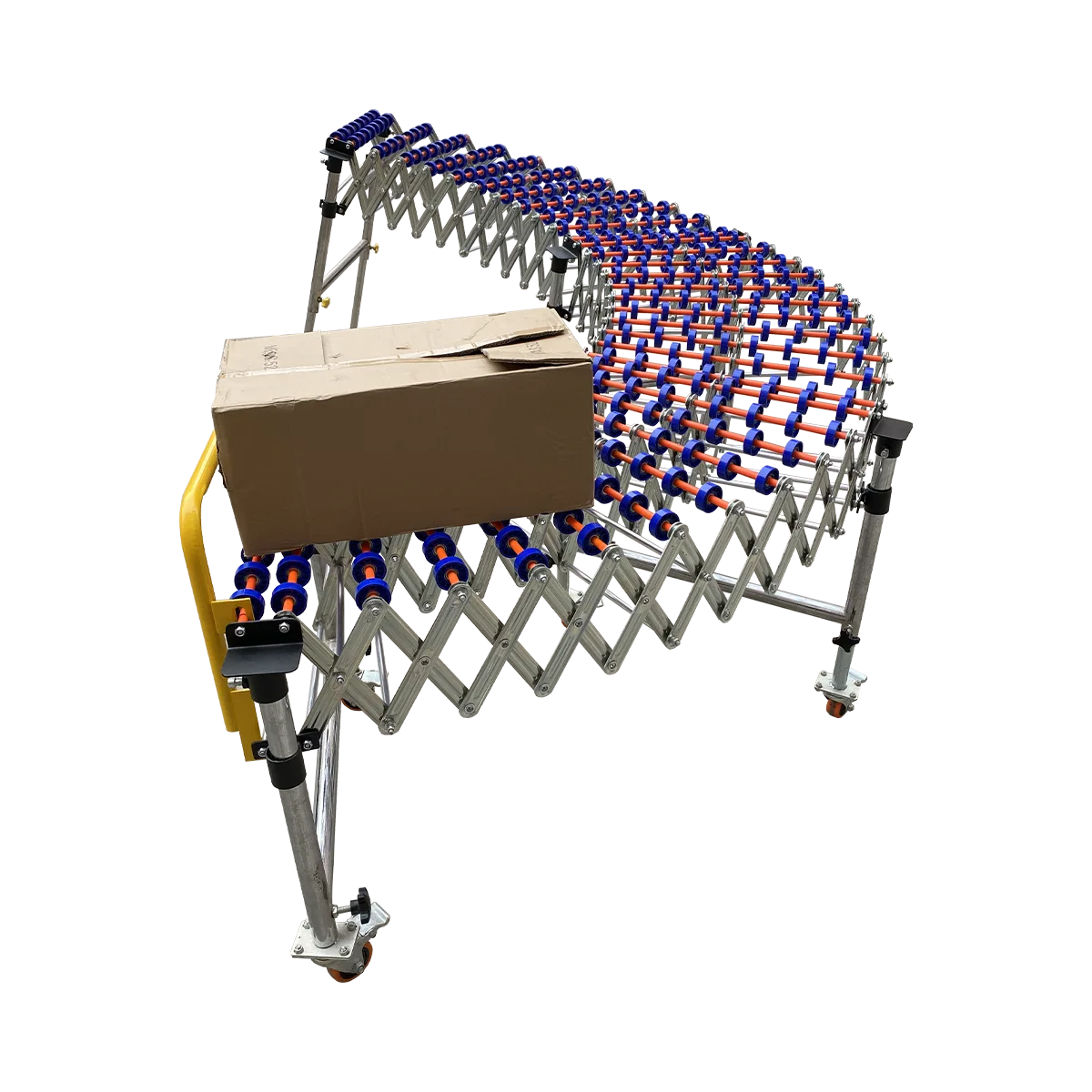

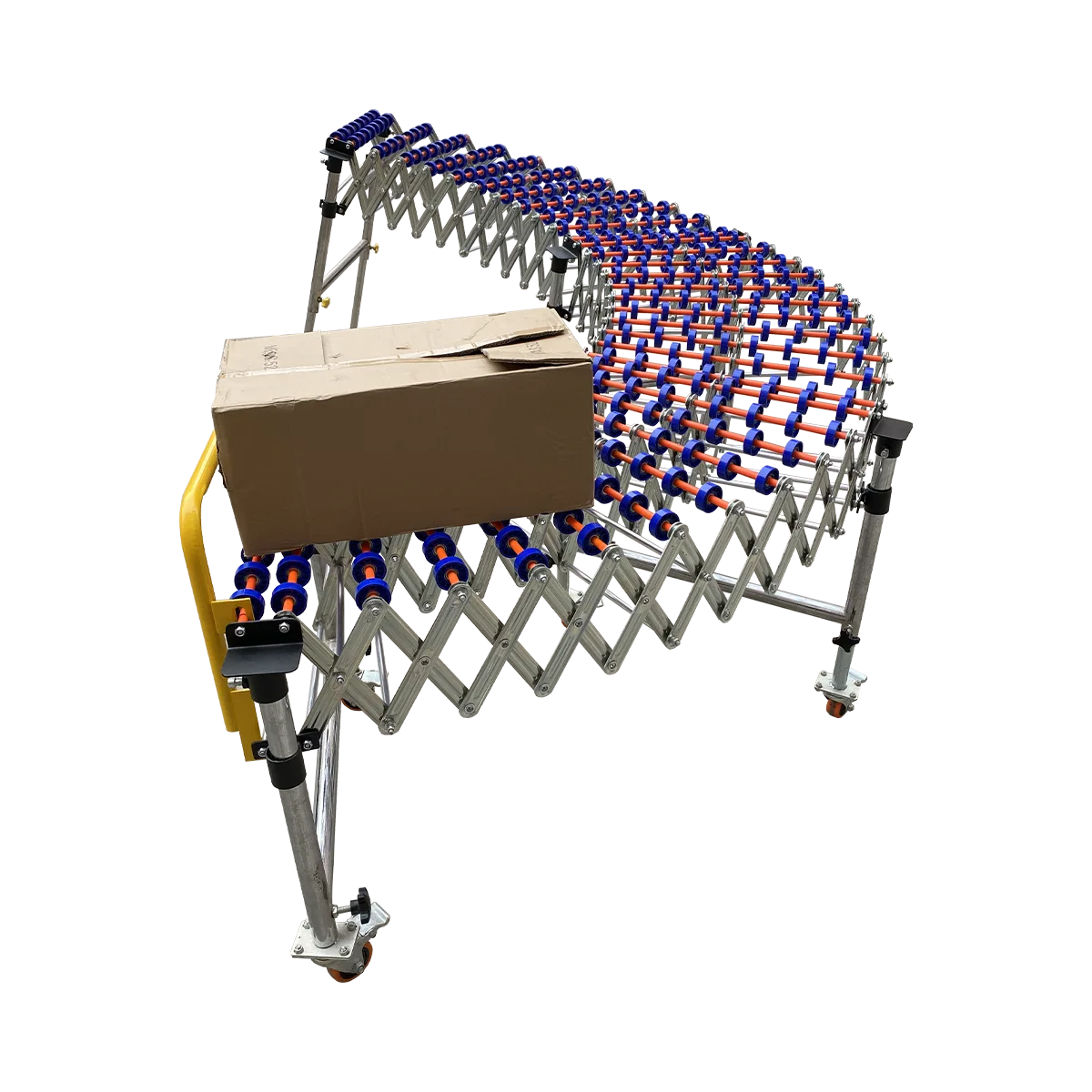

Gravity skate wheel conveyors harness natural physics for moving goods effortlessly from trucks toward processing areas. Their elegantly simple design—wheels mounted between rails—creates nearly frictionless pathways where packages travel using only gravity’s gentle pull.

Our Gravity Skate Wheel Conveyor Products

420 mm

2100 mm

50 kg/m

Flat-bottomed Goods

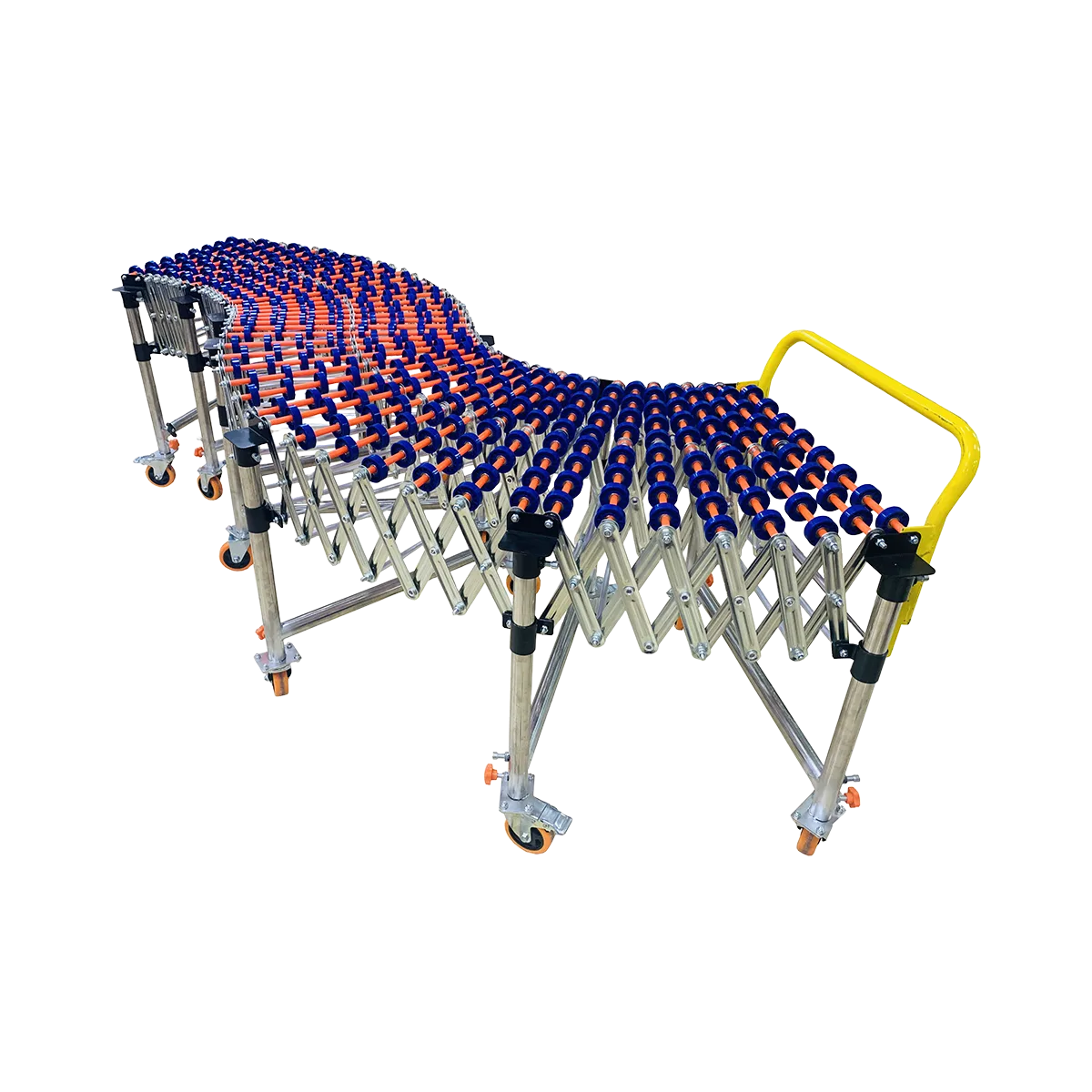

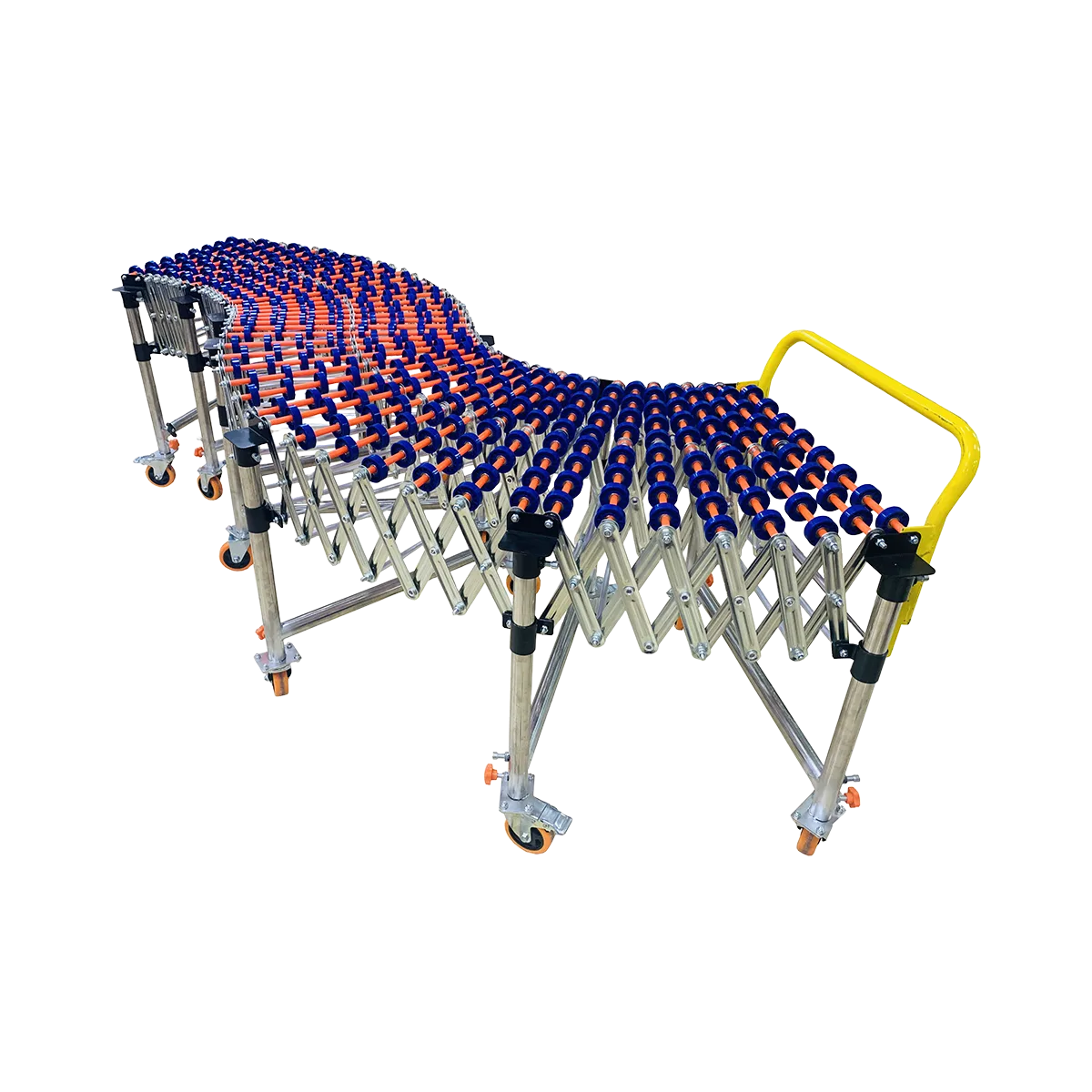

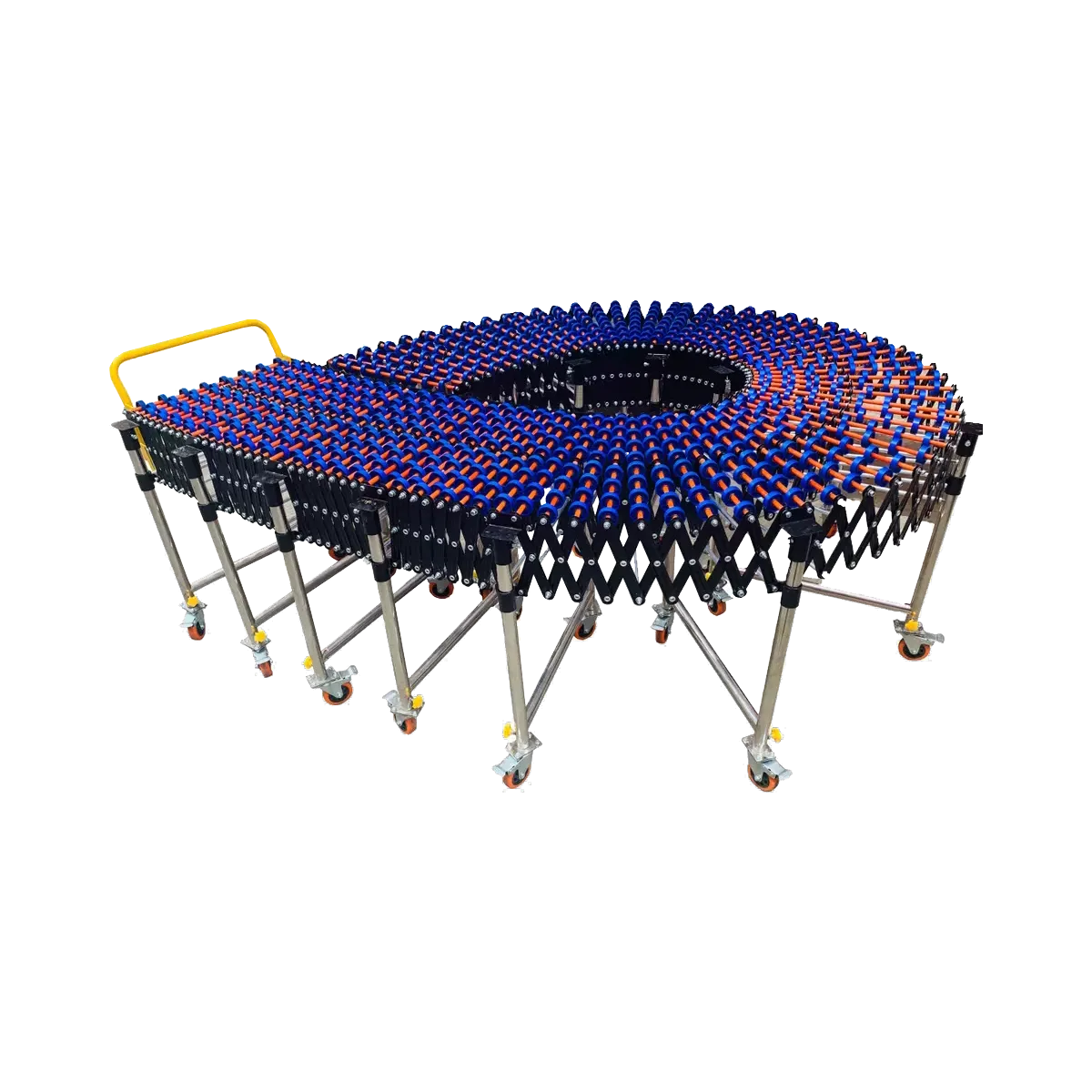

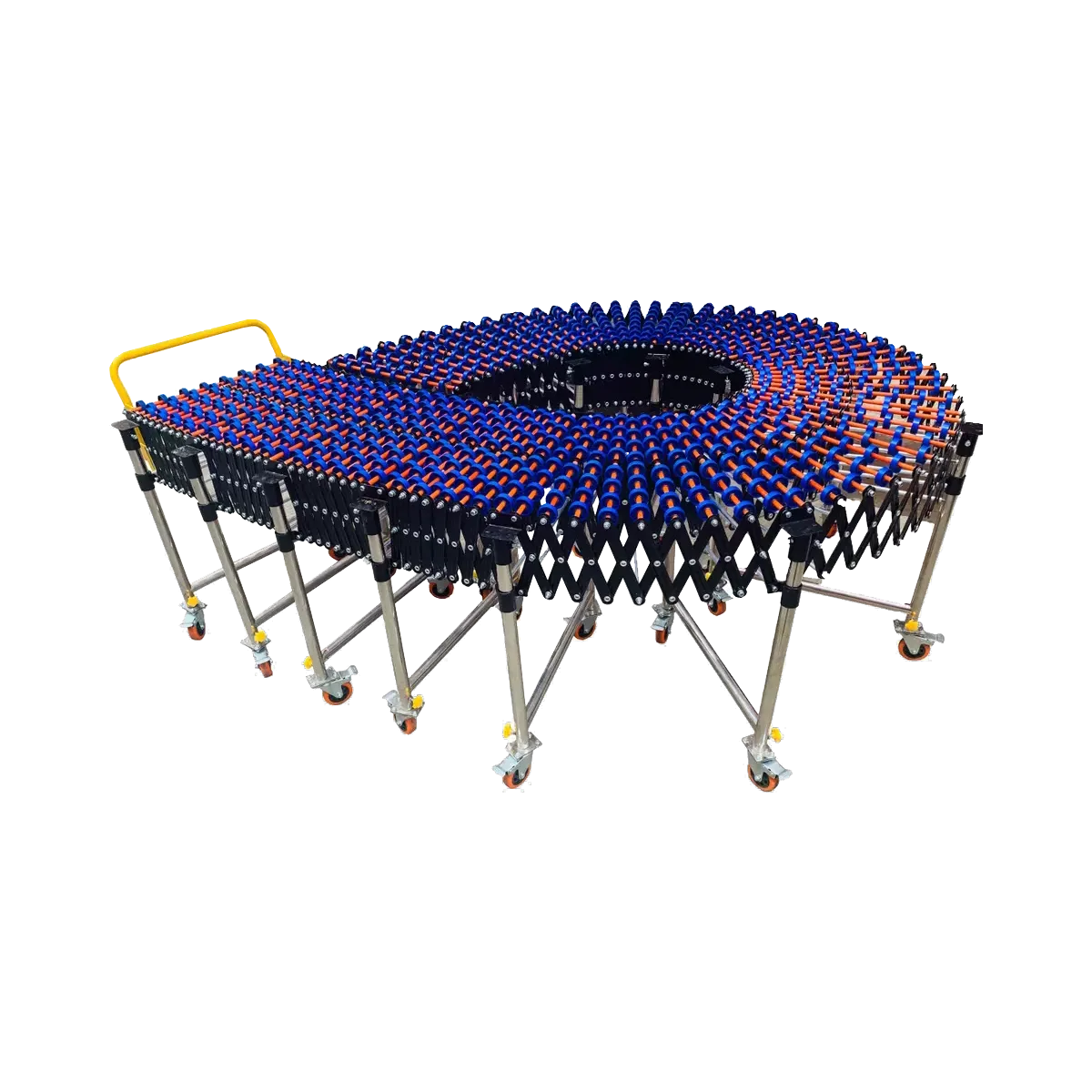

Imagine watching boxes glide smoothly across warehouse floors without motors, electricity, or maintenance headaches. Gravity skate wheel conveyors harness natural physics for moving goods effortlessly from trucks toward processing areas. Their elegantly simple design—wheels mounted between rails—creates nearly frictionless pathways where packages travel using only gravity’s gentle pull. Naili’s expandable systems stretch from compact 420 mm storage length to impressive 2100 mm reach, offering remarkable flexibility paired with robust 50 kg/meter capacity. Warehouse managers worldwide choose these energy-free solutions for unloading operations where simplicity, reliability and cost savings matter most.

Optimal Cargo Types for Gravity Skate Wheel Conveyors

Not every product moves equally well across skate wheels. Understanding which items flow smoothly helps maximize operational efficiency while minimizing handling challenges.

Boxed Products: Perfect Performers

Nothing travels better on gravity skate wheels than cardboard boxes with flat bottoms. These containers distribute weight evenly across multiple wheels creating almost magical movement quality. Distribution centers handling standard shipping cartons report exceptional results with items such as:

- Apparel boxes from clothing manufacturers

- Consumer electronics in retail packaging

- Book shipments from publishers or distributors

- Home goods in structured containers

- Office supplies with consistent dimensions

Naili’s systems feature precisely spaced wheels—11 axles per section at 150 mm intervals—ensuring smooth transitions between wheels regardless of box dimensions. This configuration virtually eliminates catching or hesitation during movement while maintaining directional stability throughout travel path.

Plastic Totes and Containers: Reliable Travelers

Reusable plastic containers with rigid bottoms perform brilliantly across gravity skate wheels. Their consistent dimensions and smooth undersides create ideal contact surfaces for reliable flow characteristics. Operations utilizing these containers experience exceptional throughput rates while maintaining product organization throughout handling processes.

| Container Type | Bottom Surface | Flow Performance | Notes |

| Straight-wall totes | Flat, rigid | Excellent | Industry standard choice |

| Nestable containers | Ribbed, structured | Very good | May require slight incline |

| Stack-and-nest bins | Reinforced edges | Good | Heavier models need steeper angle |

| Euro containers | Flat with drainage | Very good | European standard sizes flow well |

| Attached-lid containers | Flat bottom | Excellent | Security plus smooth movement |

Distribution centers report tote-handling rates increasing 30-45% after implementing gravity skate wheel systems compared with manual carrying methods. Workers appreciate dramatically reduced physical demands while maintaining precise inventory control throughout operations.

Packaged Consumer Goods: Efficient Movement

Retail products typically travel well across skate wheel conveyors thanks to standardized packaging designs. Their relatively uniform dimensions and controlled weight distribution create predictable movement patterns requiring minimal operator intervention. Common examples include:

Beverage multipacks slide beautifully across skate wheels when properly oriented. Cardboard trays holding canned or bottled products maintain stable contact points while distributing weight effectively across conveyor width. Naili’s 500/600/800 mm width options accommodate various package dimensions without adjustment requirements.

Bagged products with cardboard backing perform surprisingly well despite their potentially irregular shapes. Pet food, charcoal, lawn products—all move efficiently when reinforced facing contacts wheel surfaces. Warehouse teams appreciate how these sometimes-awkward items transport smoothly without manual carrying requirements.

Bundled paper goods travel effectively across gravity systems. Paper towels, toilet tissue, diapers—their uniform dimensions and moderate weight make them ideal candidates for skate wheel transport. Distribution centers report substantial throughput improvements when handling these high-volume consumer staples.

Electronic Equipment: Value-Added Transportation

Computer equipment and electronics benefit tremendously from skate wheel handling characteristics:

1.Minimal contact points reduce potential damage risks

2.Smooth movement prevents jarring or impact concerns

3.Controlled descent eliminates dropping hazards

4.Reduced handling requirements minimize transfer points

IT distribution operations particularly value these advantages when processing sensitive equipment. Servers, desktop systems, monitors—all travel securely across properly specified gravity conveyors without power requirements or complicated controls.

Naili’s ABS engineering plastic wheels with 608 international bearings provide especially gentle handling characteristics for technology products. Their smooth rotation eliminates vibration concerns while maintaining perfect flow control throughout transportation path.

Challenging Cargo Types: Special Considerations

While many products move effortlessly across gravity skate wheels, certain items present unique challenges requiring thoughtful application approaches.

Cylindrical Objects: Movement Management

Round items naturally want rolling sideways rather than traveling straight down conveyor paths. Effective handling requires thoughtful constraints ensuring directional control:

- Steel drums need guide rails preventing lateral movement

- Carpet rolls benefit from center guides maintaining alignment

- Tire shipments require specialized side constraints

- Paper rolls demand careful orientation monitoring

Operations handling these challenging shapes report success using modified guiderail configurations preventing unwanted rolling while maintaining forward momentum. Steeper inclines typically prove counterproductive—gentler slopes with appropriate constraints yield better results.

Soft-Bottom Packages: Flow Challenges

Items lacking rigid bottom surfaces sometimes struggle across skate wheels due to irregular contact patterns:

Flexible bags without structure may sag between wheels creating friction points. Polybags containing clothing, soft goods or irregularly shaped items typically require steeper angles or occasional operator assistance maintaining movement. Distribution centers sometimes place these packages atop rigid slipsheets improving flow characteristics substantially.

Uneven-bottom containers contact wheels irregularly creating hesitation points. Products with recessed edges or protruding features occasionally require slight assistance navigating transitions between conveyor sections. Experienced operators quickly identify problematic packages requiring minimal intervention.

Heavy or Dense Products: Weight Considerations

While Naili gravity skate wheel conveyors handle 50 kg per meter by design, weight distribution affects flow performance significantly. Dense products concentrating weight within limited areas require careful management ensuring smooth transport without component stress.

Metal parts, stone products, hardware items—these high-density materials move effectively when properly distributed across conveyor width. Operations sometimes utilize trays or pallets spreading concentrated weights across larger surface areas maintaining handling efficiency while preserving equipment integrity.

The manufacturer’s caution bears repeating: “The heavier the cargo, the greater the impact force. Please use with caution.” This practical advice reminds users that while published capacity specifications address static loads, dynamic forces during movement deserve thoughtful consideration ensuring long-term operational reliability.

Optimizing Gravity Flow Performance

Maximizing gravity skate wheel efficiency requires understanding several key operational factors affecting flow characteristics.

Incline Angle Secrets

Perfect slope creates ideal balance between movement speed and control. Too flat—packages stall mid-journey requiring intervention. Too steep—items accelerate excessively creating potential damage or safety concerns. Experienced operators recommend:

- 1.5-2° slope for standard cardboard boxes

- 2-3° incline for plastic containers or totes

- 3-4° angle for lightweight packages needing extra momentum

- Steeper sections transitioning toward gentler accumulation zones

The beauty behind adjustable support legs becomes apparent when establishing optimal angles. Naili’s systems offer heights from 450-680 mm for standard applications through 900-1500 mm for elevated requirements, allowing precise slope adjustments matching specific operational requirements.

Strategic Implementation Approaches

Thoughtful conveyor positioning dramatically improves overall efficiency:

Truck-to-staging configurations typically perform best using multiple sections. Initial steeper segments accelerate packages from vehicle interiors before transitioning toward gentler slopes maintaining controlled speed throughout longer transportation paths. This arrangement prevents excessive terminal velocity while ensuring continuous movement.

Workstation-to-workstation arrangements benefit from minimal height changes maintaining gentle product movement between processing areas. Operators appreciate controlled flow rates allowing sufficient handling time without requiring package stoppage or manual intervention.

Accumulation zones often incorporate specialized braking wheels near endpoints. These components gradually slow packages preventing impact damage while maintaining organized product arrangement at collection points. Distribution centers report substantial handling improvements through this thoughtful configuration enhancement.

Environmental Considerations

Facility conditions affect gravity performance significantly:

- Temperature fluctuations impact wheel rotation characteristics

- Humidity levels affect package bottom surface friction

- Dust accumulation potentially creates movement hesitation

- Floor vibration sometimes influences flow consistency

Regular cleaning maintains optimal performance under varying conditions. Simple weekly maintenance—removing debris, checking wheel rotation, confirming proper section alignment—preserves operational efficiency throughout changing environmental circumstances.

Application Success Stories

Real-world implementations demonstrate exceptional gravity skate wheel conveyor value across diverse operational scenarios.

E-Commerce Fulfillment Excellence

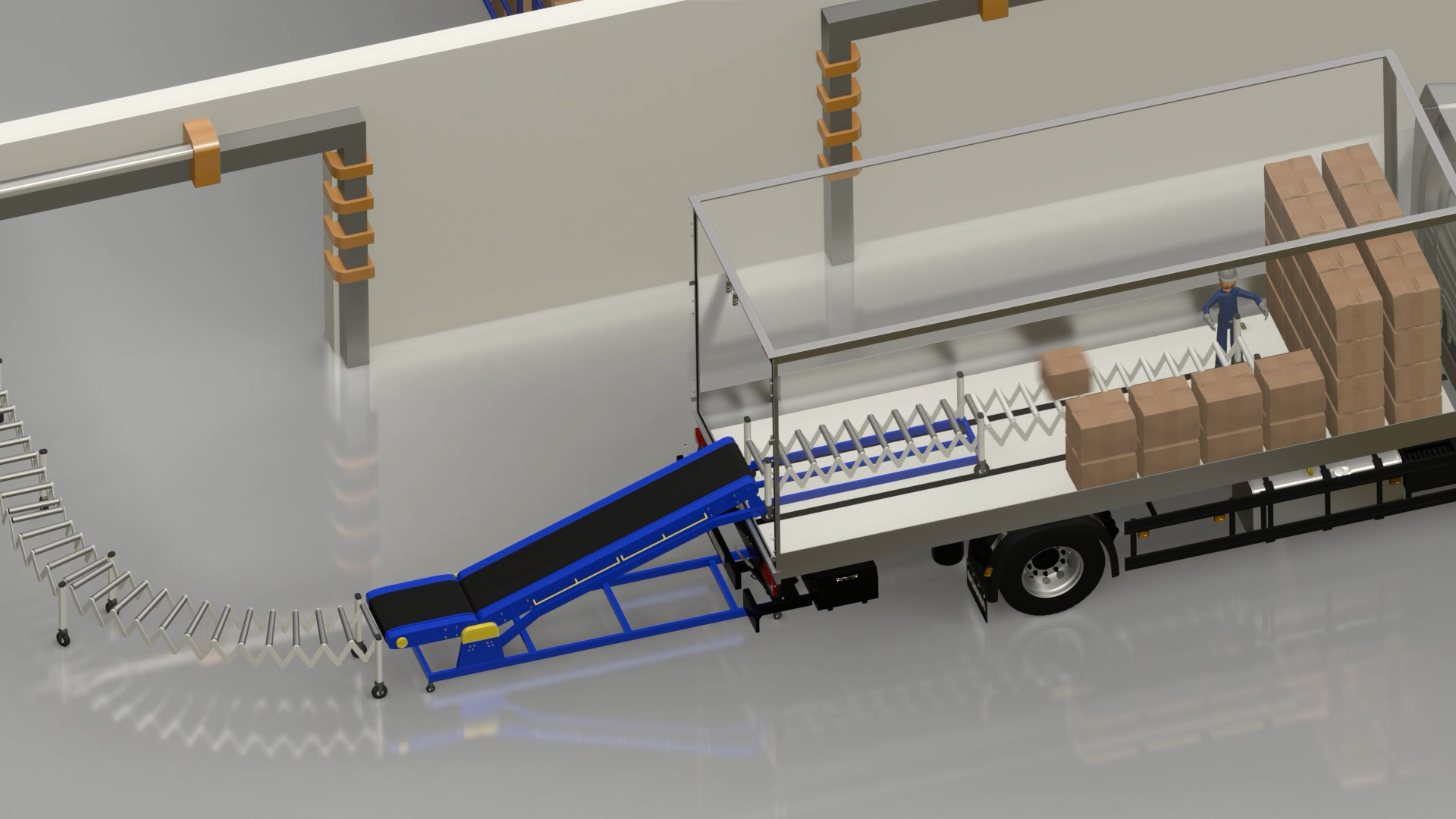

Major online retailer transformed receiving operations through strategic gravity skate wheel implementation. Their challenge: unloading 25+ delivery vehicles daily while minimizing labor requirements and maximizing throughput efficiency. Their solution: expandable gravity conveyors extending directly into truck beds where packages glide effortlessly toward sorting stations.

Results proved remarkable:

- Unloading times decreased 42% compared with manual methods

- Worker fatigue reduced substantially throughout shifts

- Product damage incidents declined nearly 60%

- Energy costs eliminated through powerless operation

Management particularly appreciated equipment flexibility—systems expanded during peak receiving periods then contracted during slower operational phases, preserving valuable floor space without compromising handling capabilities.

Distribution Center Transformation

Regional consumer goods distributor struggled with inefficient cross-docking operations until discovering gravity skate wheel advantages. Their implementation created direct pathways between receiving and shipping docks where products flowed naturally without powered assistance.

The expandable nature proved particularly valuable—systems adjusted length precisely matching varied truck positions while maintaining continuous flow pathways. Operators appreciated simple reconfiguration capabilities accommodating changing operational requirements without specialized tools or technical expertise.

Performance metrics revealed substantial improvements:

- Cross-dock cycle times improved 37%

- Labor requirements decreased 2.4 full-time positions

- Operational costs declined through eliminated power consumption

- Equipment maintenance expenses virtually disappeared

This success encouraged additional implementations throughout other facility areas, creating comprehensive gravity-powered material handling networks maximizing efficiency while minimizing operational expenses.

FAQ

Which packages work best on gravity skate wheel conveyors?

Rigid-bottom containers move most efficiently—cardboard boxes, plastic totes, electronics packaging top performance charts. Flat-bottomed packages weighing under 50 kg per meter glide smoothly requiring minimal incline angles for consistent flow.

What makes gravity systems better than powered alternatives?

Zero energy consumption, virtually maintenance-free operation, complete portability, significantly lower investment costs, plus impressive 1:5 expansion ratio from compact 420 mm storage length toward full 2100 mm operational reach—benefits accumulate quickly compared against powered systems.

Do round objects work on skate wheel conveyors?

Cylindrical items require special handling considerations including guide rails preventing sideways rolling. While not ideal candidates, properly constrained round objects travel effectively when appropriate controls maintain directional stability throughout transportation path.

What’s proper maintenance for gravity skate wheel systems?

Weekly inspections checking wheel rotation, removing debris accumulation, confirming proper section alignment typically suffice maintaining optimal performance. These simple procedures require minimal technical expertise—another significant advantage compared against mechanically complex alternatives.

Can gravity conveyors work outside loading docks?

Absolutely! Naili offers both galvanized carbon steel or 201 stainless steel construction options providing excellent weather resistance. Remember choosing appropriate models ensures reliable performance despite environmental exposure throughout operational lifespan.