Skate Wheel Conveyor Manufacturer

Home > Skate Wheel Conveyor

Skate wheel conveyors make this magic happen through brilliant simplicity. These nimble systems utilize series of wheels rather than continuous rollers, creating ultra-smooth pathways for boxes zooming from trucks onto warehouse floors.

Our Skate Wheel Conveyor Products

420 mm

2100 mm

50 kg/m

Flat-bottomed Goods

Ever watched packages zip effortlessly across warehouse floors? Skate wheel conveyors make this magic happen through brilliant simplicity. These nimble systems utilize series of wheels rather than continuous rollers, creating ultra-smooth pathways for boxes zooming from trucks onto warehouse floors. Their lightweight frames yet surprisingly sturdy construction makes them perfect for unloading operations where portability matters most. Companies worldwide choose these versatile systems when budget constraints meet high-throughput demands—proving sometimes simpler solutions deliver spectacular results without breaking budgets.

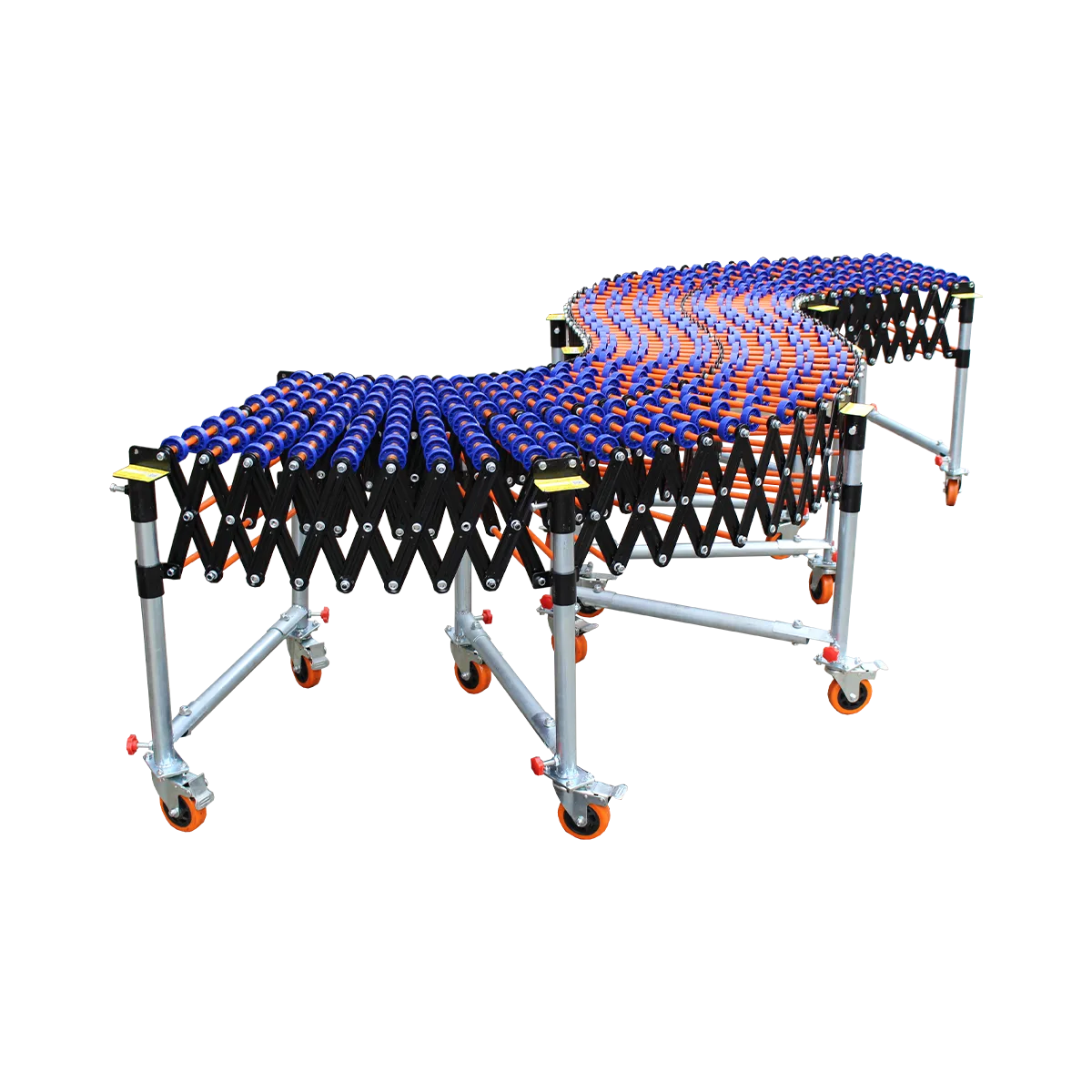

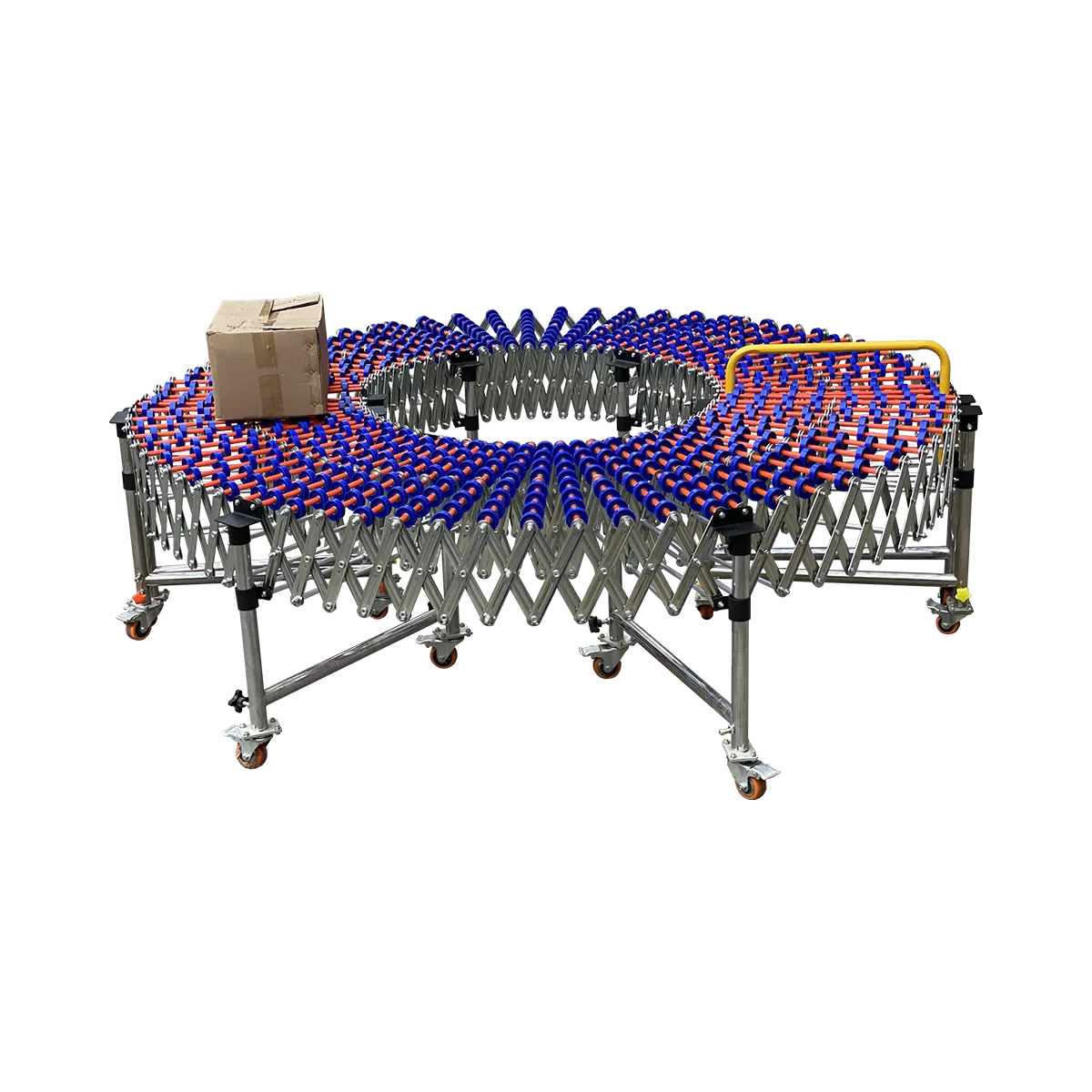

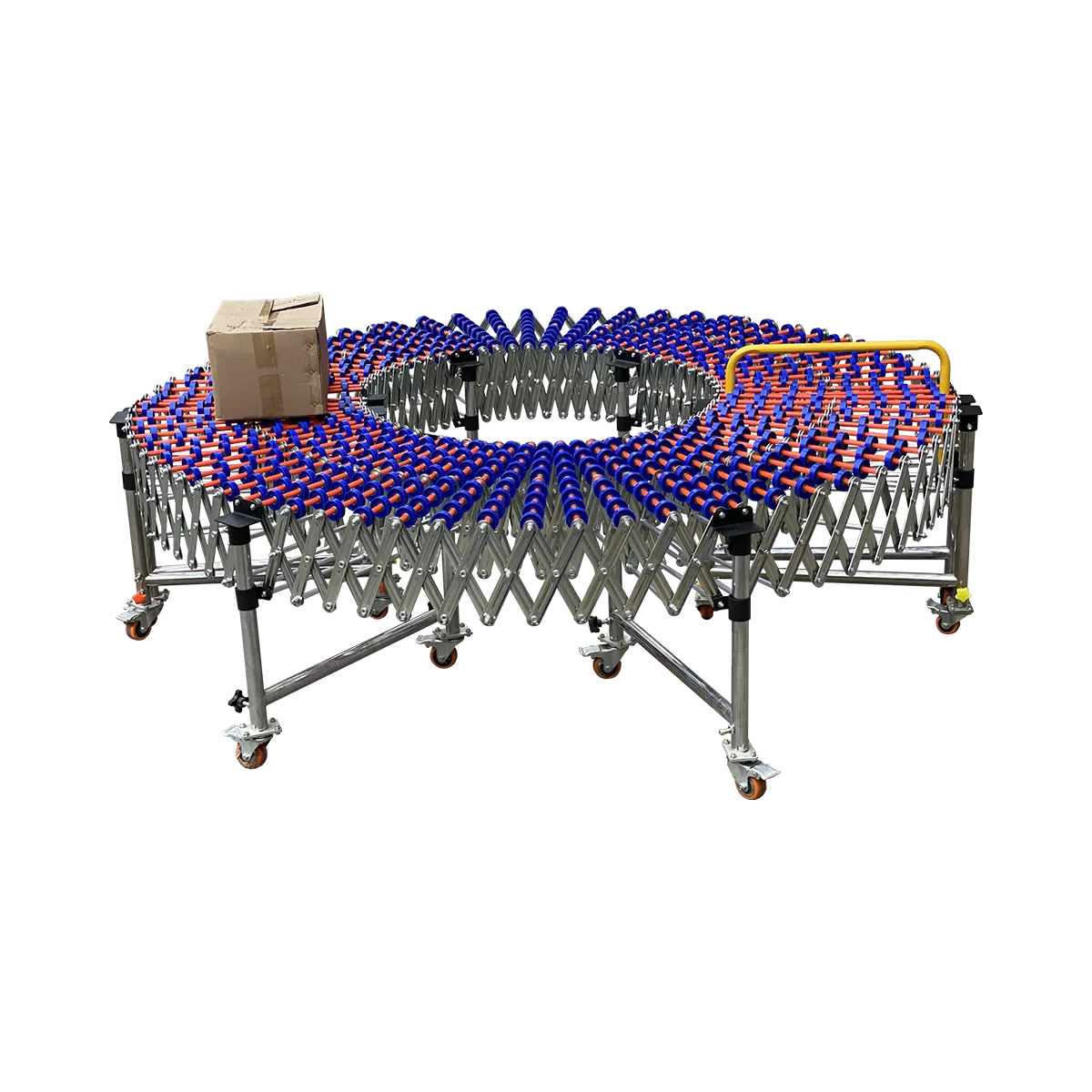

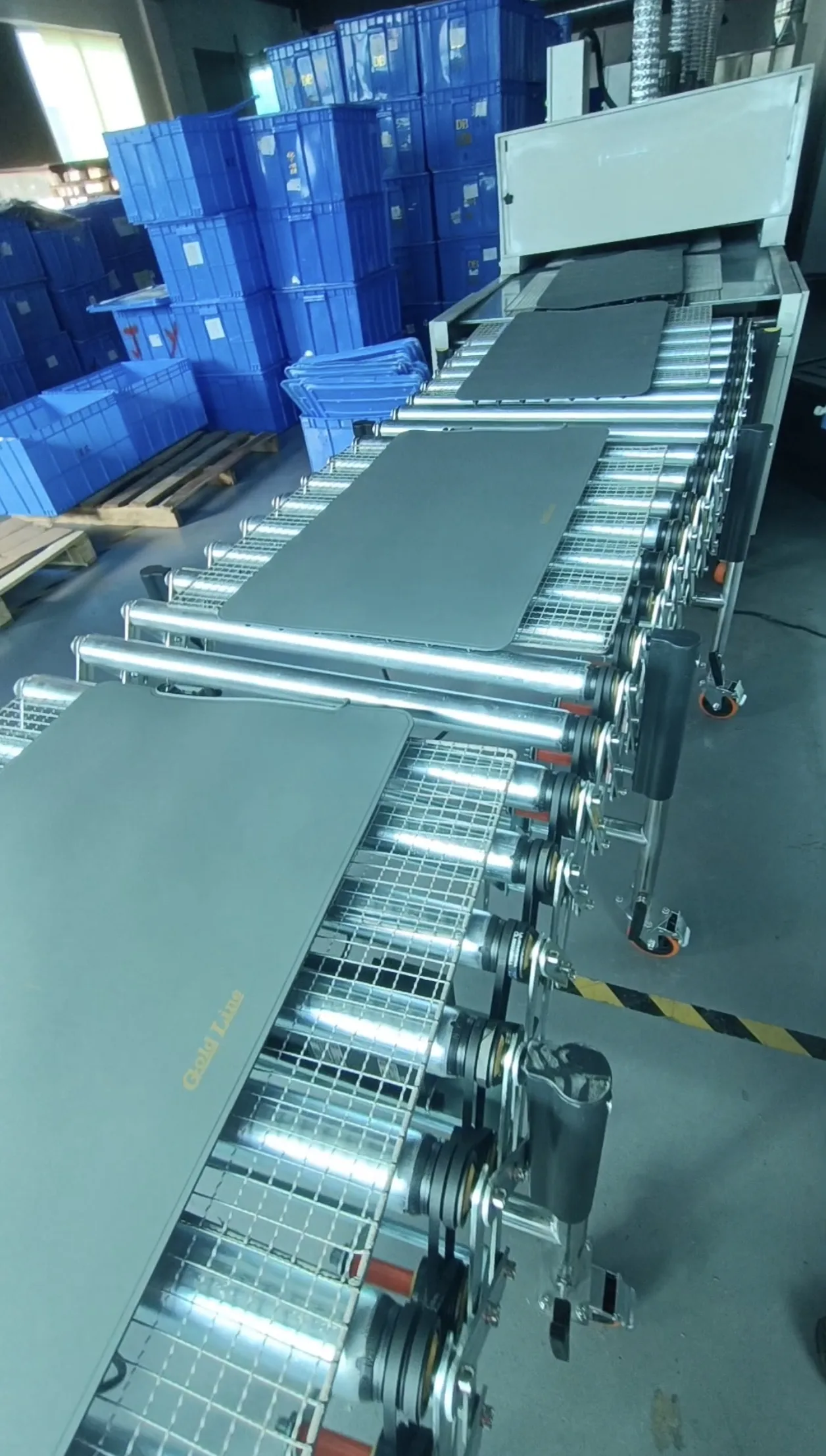

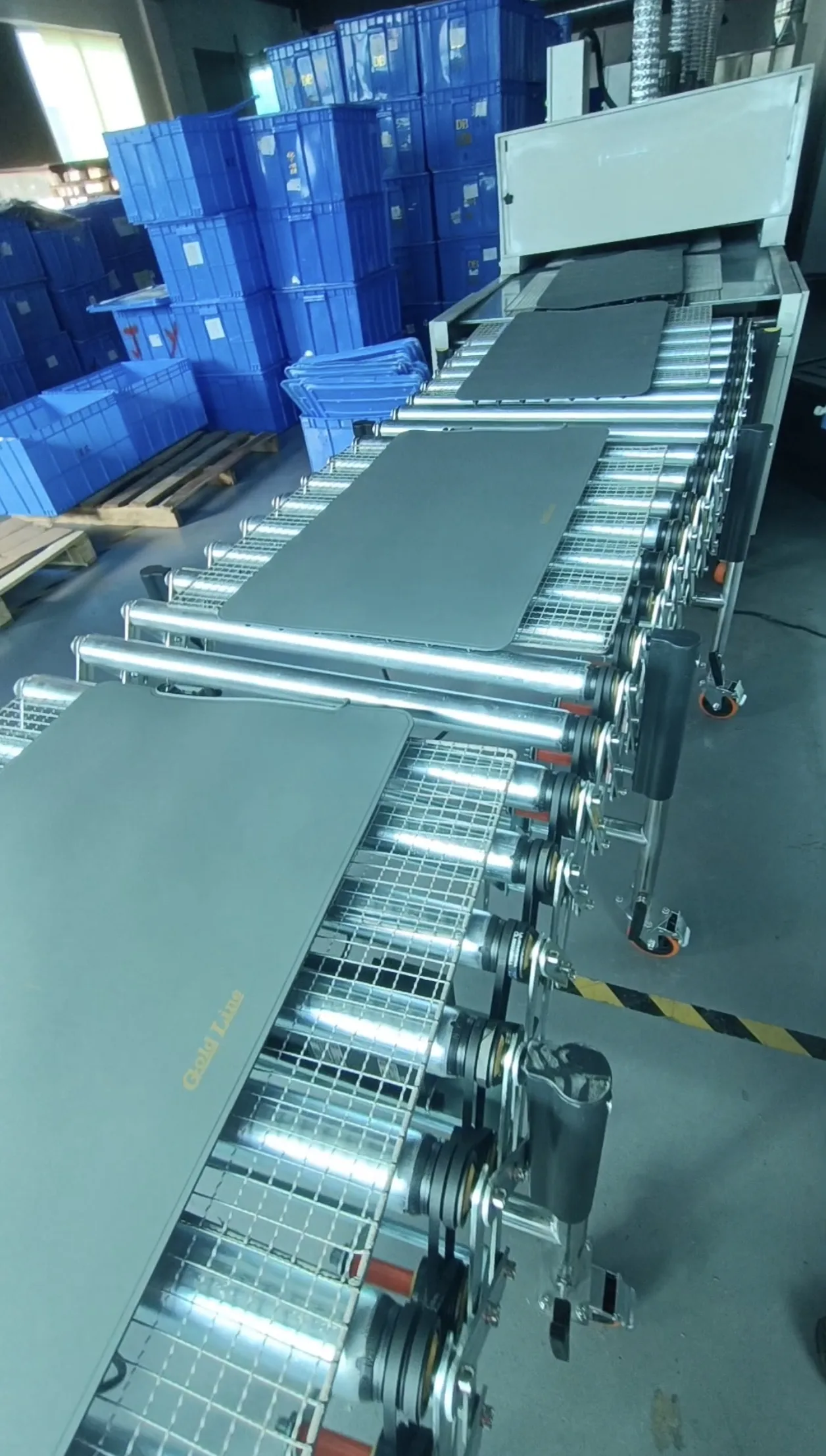

Naili’s gravity skate wheel conveyors showcase this efficiency through expandable designs. Starting at just 420 mm collapsed length, these systems stretch amazingly to 2100 mm—a remarkable 1:5 expansion ratio! Available across multiple widths (500/600/800 mm) with carrying capacities reaching 50 kg per meter, these systems combine tremendous flexibility with impressive durability.

Roller vs. Skate Wheel: Understanding Key Differences

Warehouse managers frequently debate between roller conveyors or skate wheel systems. Both transport materials effectively but fundamental differences create distinct operational advantages depending on specific needs.

Construction Contrasts

Skate wheel conveyors feature multiple individual wheels mounted along axles across frame width. This distinctive design creates several immediate advantages:

- Drastically lighter construction compared with roller alternatives

- Far less contact surface area between product and conveyor

- Significantly reduced friction during product movement

- Noticeably lower initial investment than comparable roller systems

- Remarkably simple maintenance requirements

Roller conveyors utilize continuous cylinders spanning entire width. This creates greater surface contact with transported items, providing superior weight distribution but substantially increasing overall system weight.

| Feature | Skate Wheel | Roller |

| Weight | 14-22kg per section | Substantially heavier |

| Contact Surface | Minimal (point contact) | Maximum (line contact) |

| Initial Cost | Lower investment | Higher investment |

| Load Capacity | 50kg per meter | Typically 100+ kg per meter |

| Surface Sensitivity | Requires smooth bottoms | Handles varied surfaces |

| Drive Method | Oftengravity | Both powered and gravity models |

Facility managers appreciate skate wheel affordability. Their systems typically cost 25-35% less than equivalent roller conveyors! This price advantage makes expanding material handling capabilities possible even under tight budget constraints.

Movement Mechanics

Products practically float across skate wheel systems. Minimal contact points create incredibly low friction pathways where boxes require barely any force for continued movement. This characteristic makes gravity installations particularly effective—packages maintain momentum beautifully without external power sources.

Workers love how easily products glide through unloading zones. Even heavier boxes move with surprisingly minimal effort compared with roller alternatives. This effortless movement dramatically reduces fatigue during demanding unloading sessions.

Durability Considerations

Roller conveyors generally outlast skate wheel systems under identical conditions. Their continuous design distributes weight more effectively while providing greater resistance against impact damage. Heavy industrial environments typically favor rollers for continuous high-volume operations.

Skate wheels excel wonderfully within their appropriate applications though. When used for temporary unloading zones or medium-duty applications, these systems provide excellent service life while maintaining significant cost advantages. Smart deployment based on understanding these differences ensures optimal equipment selection.

Perfect Applications for Skate Wheel Conveyors

Certain operational scenarios showcase skate wheel superiority through perfect alignment with their unique characteristics.

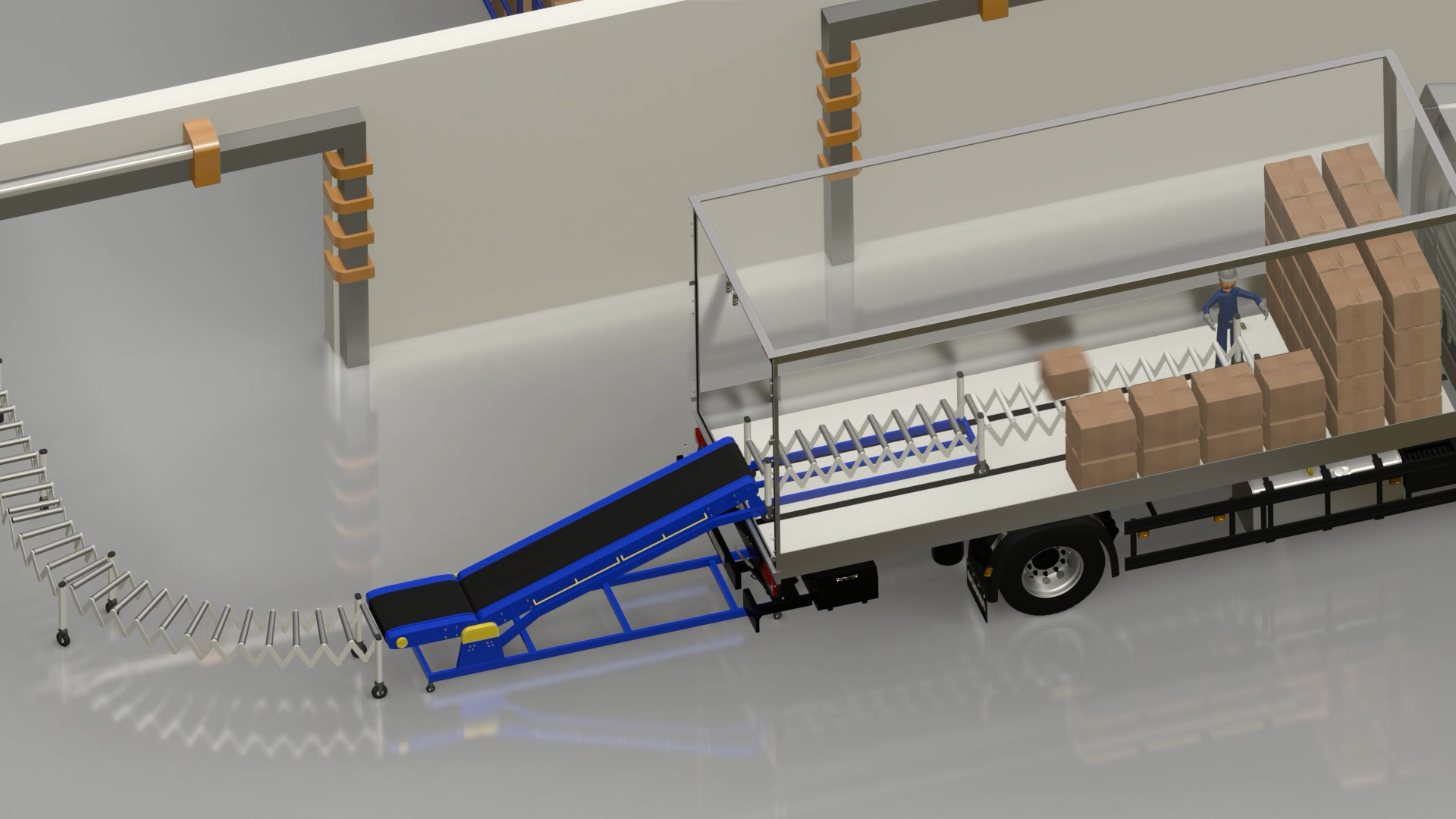

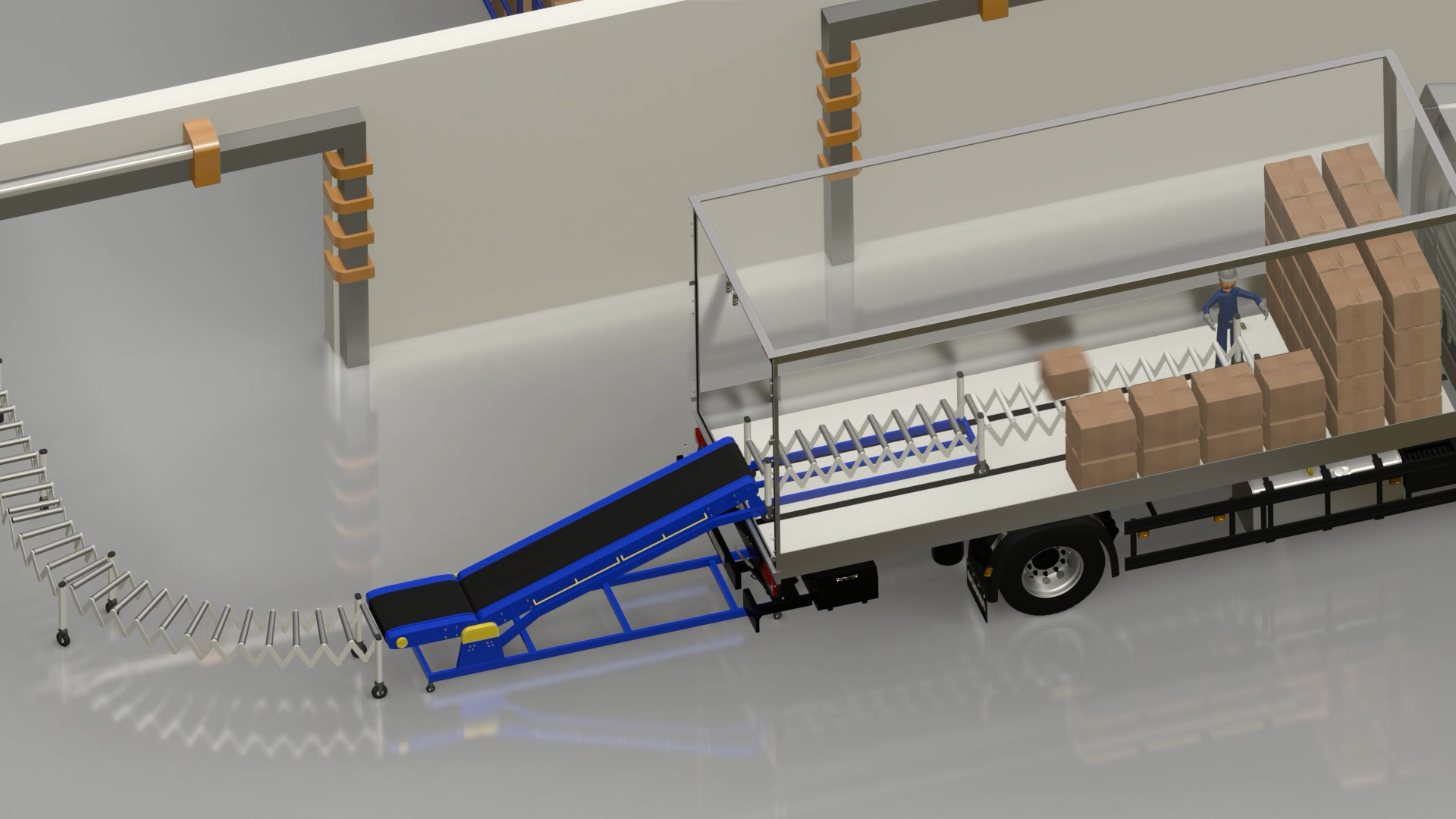

Truck Unloading Champions

Nothing beats skate wheel conveyors for fast vehicle unloading. Their ultra-light construction allows workers quickly position extensions directly into truck beds where packages slide effortlessly onto waiting conveyors. Distribution centers report unloading times reduced by up toward 40% compared with manual methods!

Gravity systems prove particularly effective when slight decline encourages natural product flow. Packages practically race from vehicles onto warehouse floors without powered assistance. This elegant simplicity translates directly into operational savings through:

1.Zero energy consumption

2.Minimal maintenance requirements

3.Reduced worker fatigue

4.Faster vehicle turnaround

managers appreciate how easily teams reconfigure unloading zones based on changing requirements. Workers position these lightweight systems wherever needed without specialized equipment or excessive effort.

Temporary Workflow Solutions

Warehouses experiencing seasonal volume fluctuations love skate wheel flexibility. These adaptable systems deploy quickly during peak periods then store compactly afterward. Retail operations particularly value this capability during holiday rushes when processing capacity must expand dramatically.

Portable sections create reconfigurable pathways accommodating changing workflow patterns. Operations managers adjust material routes responding instantly toward evolving requirements rather than remaining locked into permanent installations. This flexibility proves invaluable during layout modifications or short-term projects.

Package Sorting Applications

Distribution centers utilize skate wheel conveyors creating efficient package sorting operations. Their smooth-rolling characteristics facilitate quick directional changes as items transfer between different processing zones. Workers appreciate how products glide effortlessly between sections without jamming or hesitation.

Naili’s design features 11 skate wheel axles per section with precise 150 mm spacing between them. This configuration provides optimal support distribution across package bottoms. Models vary by width—the 500 mm usable width incorporates 66 wheels per section while 800 mm models contain 110 wheels ensuring complete package support regardless of dimensions.

Industry-Specific Advantages

Various sectors leverage unique skate wheel characteristics addressing specialized operational requirements.

E-Commerce Fulfillment

Online retailers process extraordinary package volumes daily. Skate wheel conveyors create efficient transfer paths between picking zones and shipping departments. Their lightweight construction allows frequent reconfiguration responding toward changing product mixes or seasonal demands.

Fulfillment centers report impressive throughput improvements after implementation:

- Processing 30% more packages hourly

- Reducing worker walking distance substantially

- Decreasing order completion times significantly

- Improving overall ergonomics dramatically

Workers appreciate reduced physical demands while managers celebrate productivity improvements. Using physical gravity rather than powered motors creates beautifully simple, energy-free material handling solutions generating enthusiastic adoption throughout organizations.

Distribution Centers

Package handling operations face relentless efficiency pressure. Skate wheel systems create seamless connections between receiving areas and internal processing zones. Their natural flow characteristics eliminate bottlenecks while maintaining continuous product movement.

Strategic installations create gravity zones where packages travel without external energy inputs. This approach reduces operational costs while minimizing potential failure points throughout systems. Maintenance teams particularly appreciate this mechanical simplicity during busy operational periods.

Manufacturing Support

Production environments utilize skate wheel conveyors creating flexible connections between manufacturing cells. Their easy mobility allows production line reconfiguration without extensive infrastructure changes. This adaptability proves particularly valuable during product changeovers or manufacturing process updates.

Assembly operations report workflow improvements exceeding 25% after implementation. Workers maintain focus on value-adding activities rather than material movement between stations. This efficiency directly impacts production costs while improving overall output quality.

Design Variations and Specialized Features

Skate wheel conveyors offer numerous configuration options addressing specific operational requirements through thoughtful engineering.

Frame Constructions

Various frame designs address different application needs:

Steel Channel Frames provide maximum durability for demanding environments. Their robust construction withstands impacts while maintaining proper wheel alignment throughout extended service life. High-volume operations typically select these premium options despite slightly higher initial investment.

Aluminum Extrusion Frames deliver ultimate lightweight performance. These systems practically float between locations while providing surprising strength. Mobile applications particularly benefit from this construction method despite somewhat limited maximum capacity.

Bolt-Together Systems offer wonderful modularity. Sections connect quickly creating custom configurations while maintaining disassembly capability for future modifications. Facilities facing regular layout changes appreciate this adaptable approach toward material handling.

Wheel Options and Specifications

Naili offers two primary wheel types addressing different handling needs:

| Wheel Type | Diameter | Characteristics | Best Applications |

| ABS Engineering Plastic | 48 mm | Features 608 international bearings, smooth operation, quieter | General package handling, retail goods, lighter items |

| Galvanized Iron | 48 mm | Surface-treated for durability, higher weight capacity | Industrial applications, heavier packages, extended service life |

Wheel spacing maintains consistent 150 mm gaps between axles, with each section containing 11 axle assemblies. This configuration creates ideal support for most package types while maintaining smooth product flow. The ABS spacers enhance durability through one-time injection molding techniques ensuring consistent performance throughout extended service life.

Mobility Features

Naili equips these systems with robust casters enhancing position flexibility. Featuring 30 mm width and 120 mm height, these wheels support quick repositioning while maintaining stability during operation. Distribution centers appreciate this mobility when adapting workflows toward changing operational requirements.

The remarkable expansion capability transforms handling possibilities. Engineers designed clever mechanisms extending from compact 420 mm storage length toward impressive 2100 mm operational reach. This 1:5 ratio creates tremendous flexibility within limited warehouse spaces—systems extend precisely where needed then retract when operations complete.

Implementation Best Practices

Maximizing skate wheel conveyor benefits requires thoughtful implementation strategies aligned with operational requirements.

Application Assessment

Before selecting equipment, carefully evaluate:

- Typical package dimensions and weights

- Volume throughput requirements

- Environmental conditions (temperature, moisture, contaminants)

- Available space constraints

- Integration with existing systems

- Future expansion possibilities

This thorough assessment prevents purchasing inadequate systems or overspending on unnecessary capacity. Experienced operations managers compare requirements against equipment specifications ensuring perfect alignment with organizational needs.

Layout Optimization

Strategic conveyor placement dramatically impacts overall efficiency. Consider:

1.Minimizing directional changes whenever possible

2.Creating gentle slopes rather than steep inclines

3.Positioning workstations strategically along pathways

4.Allowing adequate accumulation zones preventing bottlenecks

5.Ensuring sufficient access space for maintenance activities

Well-designed layouts reduce operational friction while maximizing throughput capacity. Even minor adjustments often yield substantial productivity improvements throughout systems.

Maintenance Considerations

Regular preventative attention significantly extends equipment lifespan:

- Scheduled wheel inspection identifying damage or excessive wear

- Frame cleaning preventing debris accumulation

- Axle lubrication ensuring smooth rotation

- Fastener verification maintaining proper tension

- Alignment checks preventing tracking problems

Simple weekly inspections typically prevent major issues while ensuring consistent performance. Most maintenance activities require minimal technical expertise—another significant advantage compared with complex powered alternatives. Naili stands behind these products with comprehensive one-year frame warranty coverage providing additional investment protection.

FAQ

How much weight can skate wheel conveyors handle?

Standard systems support 50 kg per meter as specified by manufacturer ratings. This capacity provides sufficient strength for most distribution applications while maintaining lightweight characteristics.

Do skate wheel conveyors work for oddly shaped packages?

Items require relatively smooth bottoms contacting multiple wheels simultaneously. Very irregular shapes might experience stability challenges though specialized wheel arrangements often address these concerns effectively.

What maintenance do these systems require?

Minimal attention keeps wheels turning smoothly. Regular cleaning, occasional lubrication, and periodic inspection typically suffice for most applications—dramatically simpler than powered alternatives.

Can skate wheel conveyors handle outdoor applications?

Absolutely! Naili offers both carbon steel with galvanized surface treatment or full 201 stainless steel construction. These weather-resistant options perform admirably in various environmental conditions while maintaining excellent corrosion resistance throughout extended service life.

How do skate wheel conveyors compare price-wise with roller systems?

Expect 25-35% cost savings compared with equivalent roller conveyors. This substantial difference makes skate wheel options particularly attractive for budget-conscious operations seeking maximum value.