No Loading Dock? No Problem – A Guide to Hydraulic Conveyors

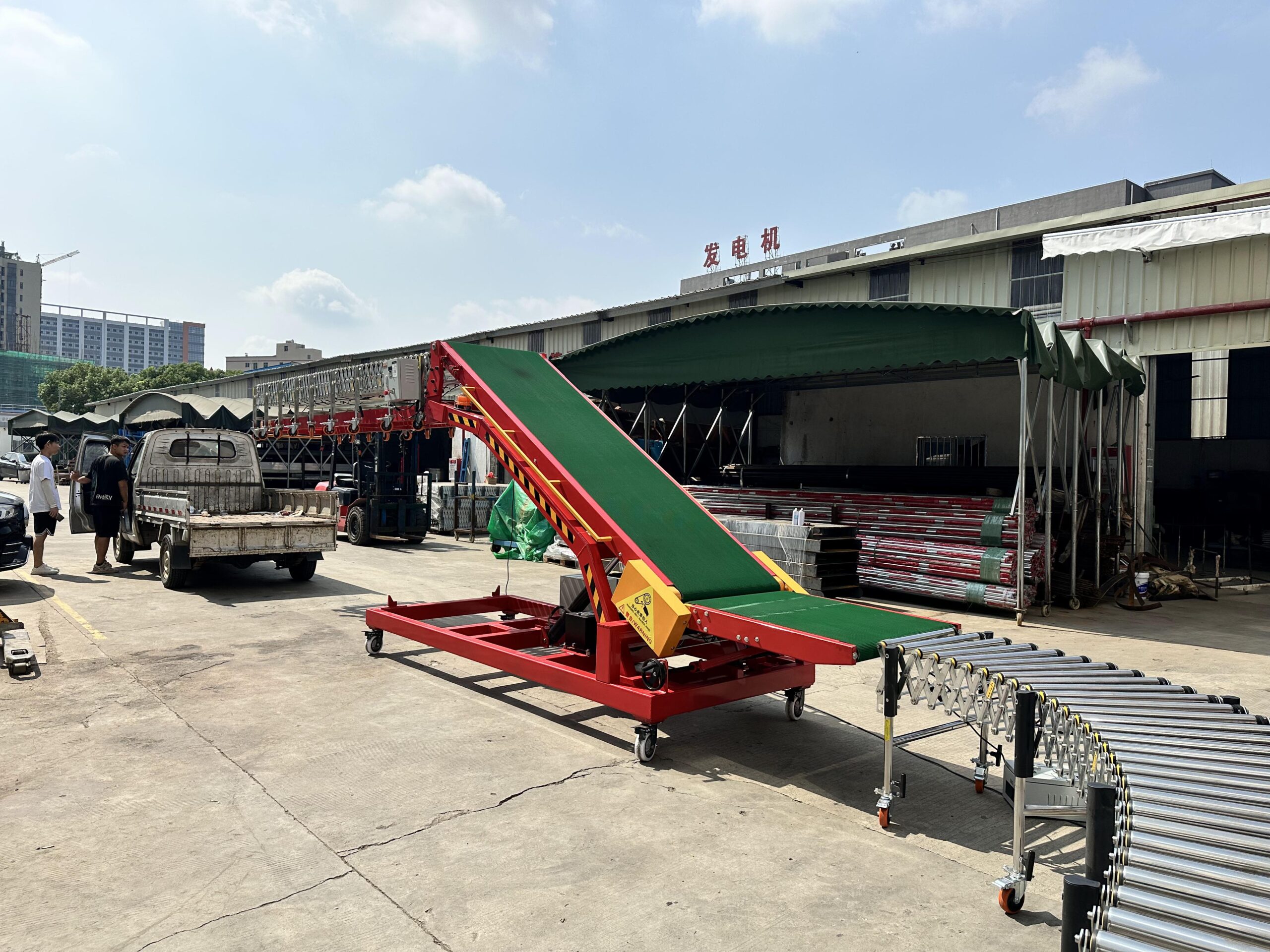

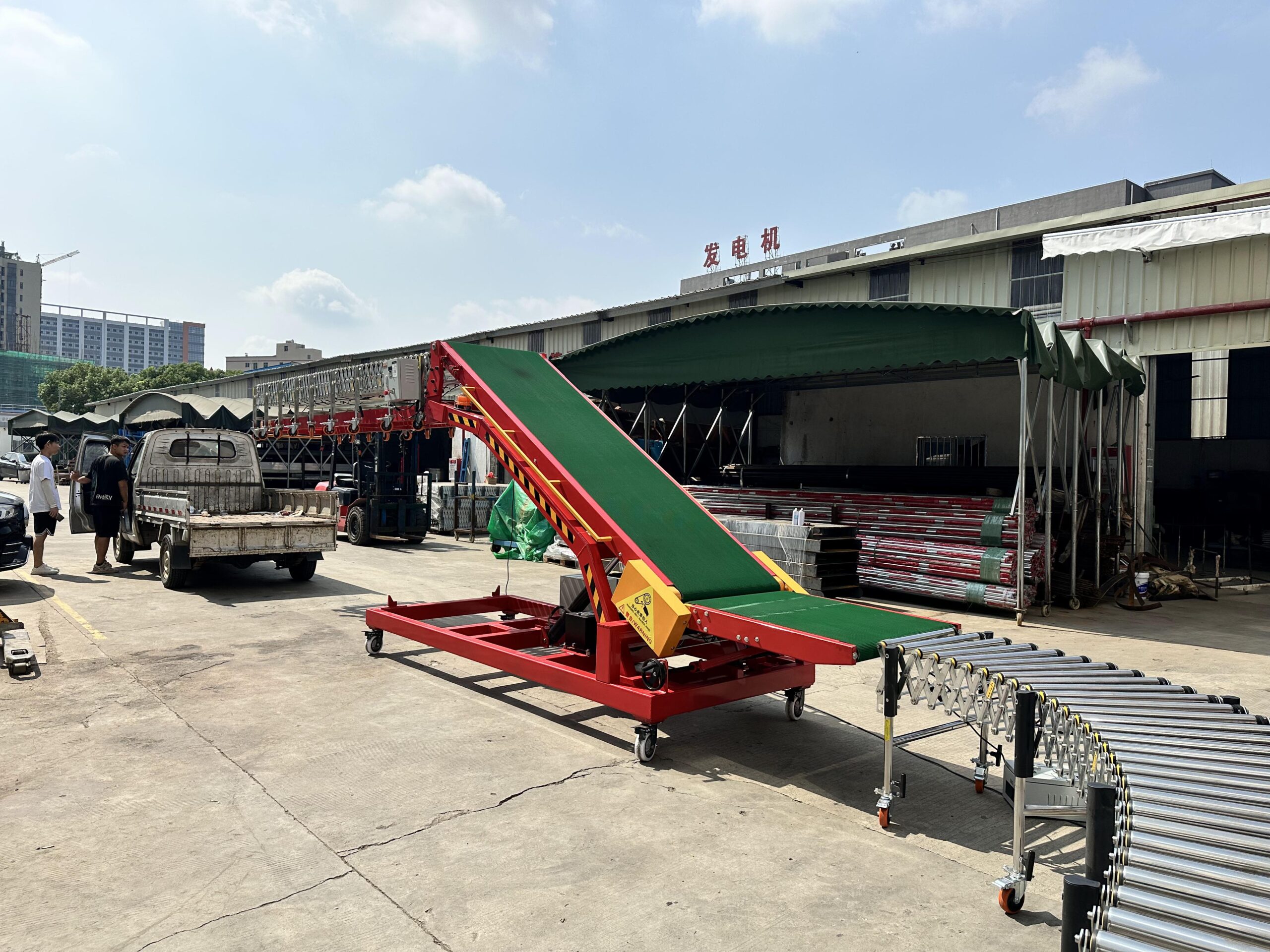

Discover how hydraulic conveyors revolutionize truck loading without a dock. These height-adjustable, portable systems bridge the gap between ground level and truck beds for efficient loading operations.

Related Products

- Hydraulic Conveyor – Large – 7900 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Hydraulic Conveyor – Medium – 7000 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Hydraulic Conveyor – Small – 5400 mm LengthCollapsed LengthExtended LengthLoad Capacity

80 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Hydraulic Conveyor – Micro – 3700 mm LengthCollapsed LengthExtended LengthLoad Capacity

50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

Every warehouse manager knows the struggle: trying to load or unload cargo when there’s a significant height difference between your warehouse floor and the truck bed. Without a proper loading dock, this simple height mismatch creates costly inefficiencies, worker fatigue, and potential safety hazards. Manual lifting becomes the default solution, slowing operations and increasing injury risks.

For businesses operating without dedicated loading docks, this challenge repeats with every shipment. The constant lifting, carrying, and maneuvering of goods across this height gap not only exhausts workers but also damages products and extends loading times significantly.

Introducing the Hydraulic Conveyor: Your Flexible Loading Dock

The hydraulic conveyor offers an elegant solution to this persistent logistical challenge. Acting as a portable, adjustable loading dock, this dynamic system creates an inclined bridge between ground level and truck beds of varying heights.

How it works: Using hydraulics to create an incline for loading/unloading

Hydraulic conveyor systems utilize powerful hydraulic cylinders to adjust their incline angle, creating a smooth transition between ground level and truck height. The system consists of a sturdy conveyor belt mounted on an adjustable frame that can be raised or lowered as needed.

When a truck arrives for loading or unloading, operators simply position the hydraulic conveyor at the truck’s rear, adjust the height using the control panel, and begin operations. Goods placed on one end smoothly travel up (or down) the incline, eliminating manual lifting across the height gap.

The beauty of this system lies in its precise height adjustability—capable of accommodating vehicles from small delivery vans to full-sized shipping containers. The conveyor belt provides consistent, controlled movement of goods, while the sturdy frame ensures stability during operation.

Top 5 Advantages of Using a Hydraulic Conveyor

Height adjustability for any vehicle

One of the most significant advantages of hydraulic conveyor systems is their remarkable adaptability to different vehicle heights. Naili’s hydraulic conveyors can be adjusted from a minimum height of 700mm to a maximum of 2400mm, depending on the model. This versatility means a single piece of equipment can serve your entire fleet—from small delivery vans to full-sized shipping containers.

The hydraulic lift mechanism allows for quick, precise adjustments, letting you create the optimal incline angle for different cargo weights and box sizes. Unlike fixed loading docks that serve only vehicles of a specific height, hydraulic conveyors adapt to your operational needs rather than forcing your operations to adapt to infrastructure limitations.

Portability: Move it where you need it

Traditional loading docks are permanent fixtures that lock you into a fixed workflow. Hydraulic conveyors break this limitation by offering genuine mobility. Equipped with heavy-duty casters (50mm wide, 200mm height with full braking capability), these systems can be easily relocated by just two workers.

This portability transforms your loading capabilities:

- Position the conveyor exactly where needed for each truck

- Adapt to changing workflow needs throughout the day

- Utilize multiple loading/unloading zones without additional construction

- Store the equipment when not in use to free up valuable warehouse space

For businesses with limited space or varying operational needs, this mobility creates loading dock functionality without the permanent infrastructure commitment.

Modular design: Connecting with roller conveyors to reach deep into the truck

Hydraulic conveyors truly shine in their modular expandability. The upper platform of most models (except Micro) features support brackets designed to accommodate various types of roller conveyors, significantly extending their reach.

This innovative design allows you to:

- Extend the conveyor system deep into truck beds and containers

- Configure different system lengths based on specific vehicle depths

- Exchange different conveyor types based on cargo requirements

For example, Naili’s Medium Hydraulic Conveyor can support roller conveyors extending up to 10 meters, while the Large model supports extensions up to 12 meters—sufficient to reach the deepest sections of shipping containers and trucks.

This modular approach means you’re not limited to merely bridging the height gap; you can create a complete loading system that reaches exactly where you need it.

Cost-effective alternative to building a permanent dock

Building a permanent loading dock requires significant investment:

- Construction costs for the dock structure

- Potential building modifications

- Permits and regulatory compliance

- Lost operational space

- Permanent commitment to a fixed configuration

By contrast, hydraulic conveyors provide equivalent functionality at a fraction of the cost. The initial investment quickly pays dividends through increased operational efficiency without the commitment and expenses of permanent construction.

For operations handling over 1000 packages daily, hydraulic conveyor systems typically achieve return on investment within 6-12 months through labor savings and efficiency improvements.

Improving safety and efficiency

Traditional manual loading/unloading across height differences creates significant safety risks through repeated lifting, awkward positions, and potential falls. Hydraulic conveyors dramatically reduce these hazards by:

- Eliminating the need for manual lifting between height levels

- Providing stable, controlled product movement

- Reducing worker fatigue through mechanical assistance

- Lowering the risk of dropped or damaged merchandise

Efficiency gains are equally impressive. What previously required multiple workers can now be accomplished with just two employees—one placing items on the conveyor and another receiving them. This streamlined process increases throughput while reducing labor costs and physical strain.

Exploring Naili’s Hydraulic Conveyor Models (Micro, Small, Medium, Large)

Naili offers four distinct hydraulic conveyor models, each designed for specific operational needs:

Micro Hydraulic Conveyor – 3700mm Length

The Micro model is Naili’s most compact hydraulic conveyor solution, ideal for small delivery vans and operations with limited space:

- Key specifications: 3700mm total length, 50kg/m load capacity

- Height range: 700mm to 1700mm

- Unique feature: The only model that doesn’t support extension with additional roller conveyors

- Best for: Small delivery operations, confined spaces, lightweight packages

Small Hydraulic Conveyor – 4000mm Length

The Small model balances compactness with versatility:

- Key specifications: 4000mm total length, 80kg/m load capacity

- Height range: 700mm to 1820mm

- Extension capacity: Support brackets accommodate up to 6 meters of roller conveyors

- Best for: Standard delivery trucks up to 7.2 meters deep

Medium Hydraulic Conveyor – 7000mm Length

The Medium model offers professional-grade capacity for most logistics operations:

- Key specifications: 7000mm total length, 80kg/m load capacity

- Height range: 700mm to 2400mm

- Extension capacity: Support brackets accommodate up to 10 meters of roller conveyors

- Best for: Any standard shipping container or freight truck

Large Hydraulic Conveyor – 7900mm Length

The Large model represents Naili’s most robust hydraulic conveyor solution:

- Key specifications: 7900mm total length, 80kg/m load capacity, includes a 3500mm roller frame section

- Height range: 700mm to 2400mm

- Extension capacity: Support brackets accommodate up to 12 meters of roller conveyors

- Best for: Maximum reach applications, high-volume operations, full container loading/unloading

Which model fits your truck size and volume?

Selecting the right hydraulic conveyor depends primarily on your vehicle types and operational volume:

- For small delivery vans and limited operations: Micro model

- For standard trucks up to 7.2 meters deep: Small model

- For containers and larger trucks: Medium or Large models

- For maximum extension capability: Large model

Consider both your current needs and potential future requirements when selecting a model.

Real-World Applications: Who Benefits Most?

Warehouses without docks

For facilities constructed without loading docks, hydraulic conveyors provide immediate loading capability without expensive building modifications. This is especially valuable for:

- Leased spaces where permanent modifications aren’t permitted

- Growing businesses that haven’t yet invested in permanent infrastructure

- Operations in buildings with physical constraints preventing dock construction

- Multi-purpose spaces that can’t dedicate permanent areas to loading functions

Rental properties or temporary sites

Businesses operating in temporary or rented locations face unique challenges in creating efficient loading solutions without permanent alterations. Hydraulic conveyors offer:

- Full loading dock functionality without structural changes

- Complete mobility when relocating

- No restoration costs when vacating a property

- Flexibility to reconfigure operations as needed

Businesses with diverse vehicle fleets

Companies managing mixed fleets of delivery vans, trucks, and containers struggle with fixed-height loading solutions. The height adjustability of hydraulic conveyors provides:

- Universal compatibility across all vehicle types

- Elimination of specialized equipment for different vehicle heights

- Streamlined operations through standardized loading procedures

- Maximum utilization of a single piece of equipment

Bridge the Gap with Naili’s Hydraulic Conveyor Systems

In today’s fast-paced logistics environment, the absence of a traditional loading dock should never limit your operational efficiency. Naili’s hydraulic conveyor systems provide a versatile, portable solution that transforms any space into a fully functional loading zone.

By combining height adjustability, portability, and modular design, these systems effectively bridge the gap between ground-level operations and vehicle beds of any height. The result is faster loading times, reduced physical strain, fewer product damages, and ultimately, significant cost savings.

Whether you’re operating from a temporary location, managing a diverse vehicle fleet, or simply looking for a more flexible alternative to permanent loading docks, hydraulic conveyors deliver enterprise-grade loading capabilities without the constraints of fixed infrastructure.

Investing in a hydraulic conveyor doesn’t just solve an immediate operational challenge—it opens new possibilities for how and where you can efficiently move inventory through your supply chain.

Frequently Asked Questions

How do hydraulic conveyors compare to permanent loading docks in terms of efficiency?

Hydraulic conveyors offer comparable loading/unloading efficiency to permanent docks with the added benefits of mobility and adjustable height. While permanent docks may provide slightly faster operations in high-volume environments, hydraulic conveyors typically deliver 90-95% of the efficiency without the permanent infrastructure commitment.

What maintenance is required for a hydraulic conveyor?

Regular maintenance includes monthly hydraulic oil level checks, quarterly inspections of hydraulic seals and bearings, and periodic lubrication of moving parts. The conveyor belt should be examined weekly for proper tension and wear signs. With proper maintenance, these systems typically provide 5-10+ years of reliable service.

Can hydraulic conveyors handle fragile or irregularly shaped items?

Yes, the PVC 5.0mm black grass pattern anti-slip belt provides excellent grip and stability for various item types. The controlled incline and consistent speed (30 m/min) ensure smooth transport of both regular boxes and irregularly shaped goods, reducing handling damage compared to manual lifting.

What power requirements do hydraulic conveyors have?

Naili hydraulic conveyors require standard power connections (220V/380V) for both the conveyor belt motor (750W) and hydraulic pump (typically 2.2kW). A stable power supply is recommended, and proper grounding is essential for safe operation.

Is it possible to connect hydraulic conveyors to existing warehouse conveyor systems?

Yes, hydraulic conveyors are designed to integrate with existing warehouse logistics systems. They can be positioned to receive products from fixed conveyor lines and transfer them directly to trucks, or vice versa. The modular design allows for seamless workflow integration without major infrastructure changes.

Table of Contents

Recent Posts

Optimize hardware store logistics with the right building supply conveyor systems. Our guide to tool distribution systems enhances retail warehouse automation for efficient operations.

Optimize your medical supply logistics with efficient gravity conveyor systems. Learn how to safely handle healthcare products while improving your hospital supply chain operations.

Discover how a sports equipment conveyor system can streamline your athletic gear logistics. Flexible conveyor solutions for all shapes and sizes of sporting goods.