TeleScopic Conveyor – 3 Sections

The TeleScopic Conveyor – 3 Sections is a compact, high-performance solution for loading and unloading operations. With adjustable speeds of 10-40 m/min and a load capacity of 60 kg/m², it is ideal for handling various cargo sizes. Powered by 1.5 kW and 0.4 kW motors, it extends up to 9,500 mm, making it suitable for medium-sized trucks and containers. The 3 mm PVK impact-resistant belt ensures durability, and the conveyor features customizable options like hydraulic lifts, operator platforms, and mobility casters for enhanced flexibility. Perfect for tight spaces and high-efficiency logistics.

Propduct Model

Key Parameters

Minimun Speed

10

m/min

Maximun Speed

40

m/min

Load Capacity

60

kg/m²

Equipment Parameters

| Item | Parameters |

| Conveying Speed | 10-40 m/min (frequency adjustable) |

| Rated Load | ≤ 60 kg/m² |

| Motor | Conveying motor: 1.5 kW Taibang, Naixin<br>Telescoping motor: 0.4 kW Taibang, Naixin |

| Telescoping Speed | 10 m/min (frequency adjustable) |

| Belt | 3 mm PVK impact-resistant composite belt (steel buckle joint) |

| Electrical | 6 W/LED lighting × 2, Shengbang inverter (proportional to motor power), independent power distribution box, Chint electrical components |

| Cable Drag Chain | Cables: Dow (China), Jinhuan Yu, Jinlong Yu (copper conductors and wires), Drag Chain: Cargotec, Igus, Xin Pengrui |

| Bearing | Built-in bearings: Harbin/Renben, Bearing seat: TR/Renben/FSB |

| Optional Items | Hydraulic lift, operator platform, hump, electric casters, moving casters, counter, top sweep |

| Plate Thickness | Main beam: (fixed section) 6 mm and above BS700 or T700 and above steel plate bending (height 565 mm and above) Secondary beam: (first extending section) 5 mm and above BS700 or T700 and above steel plate bending (height 308 mm and above) Secondary beam: (second extending section) 5 mm and above BS700 or T700 and above steel plate bending (height 165 mm and above) |

| Drive Roller | Φ 140 × 850 seamless steel pipe precision manufacturing, surface rubber coating ≥ 10 mm, wall thickness ≥ 6 mm, spindle 45# steel quenching |

| Driven Roller | Φ 89 × 750 and 850 seamless steel pipe precision manufacturing, wall thickness ≥ 6 mm, spindle 45# steel quenching, pressure belt roller Φ 50 mm |

| Hydraulics | Hydraulic angle: 3.5°, mounting hole distance 620 mm, stroke 285 mm |

Other Parameters

| Fixed Section (mm) | Max Extension (mm) | Height (mm) | Equipment Weight (t) |

| 4000 | 5000 | ≥ 580 | 1.4 |

| 5000 | 7000 | ≥ 580 | 1.6 |

| 6000 | 8000 | ≥ 580 | 1.8 |

| 6000 | 8500 | ≥ 580 | 1.8 |

| 7000 | 9000 | ≥ 580 | 2 |

| 7000 | 9500 | ≥ 580 | 2 |

Related Products

Load Capacity

60 kg/m

Length Range

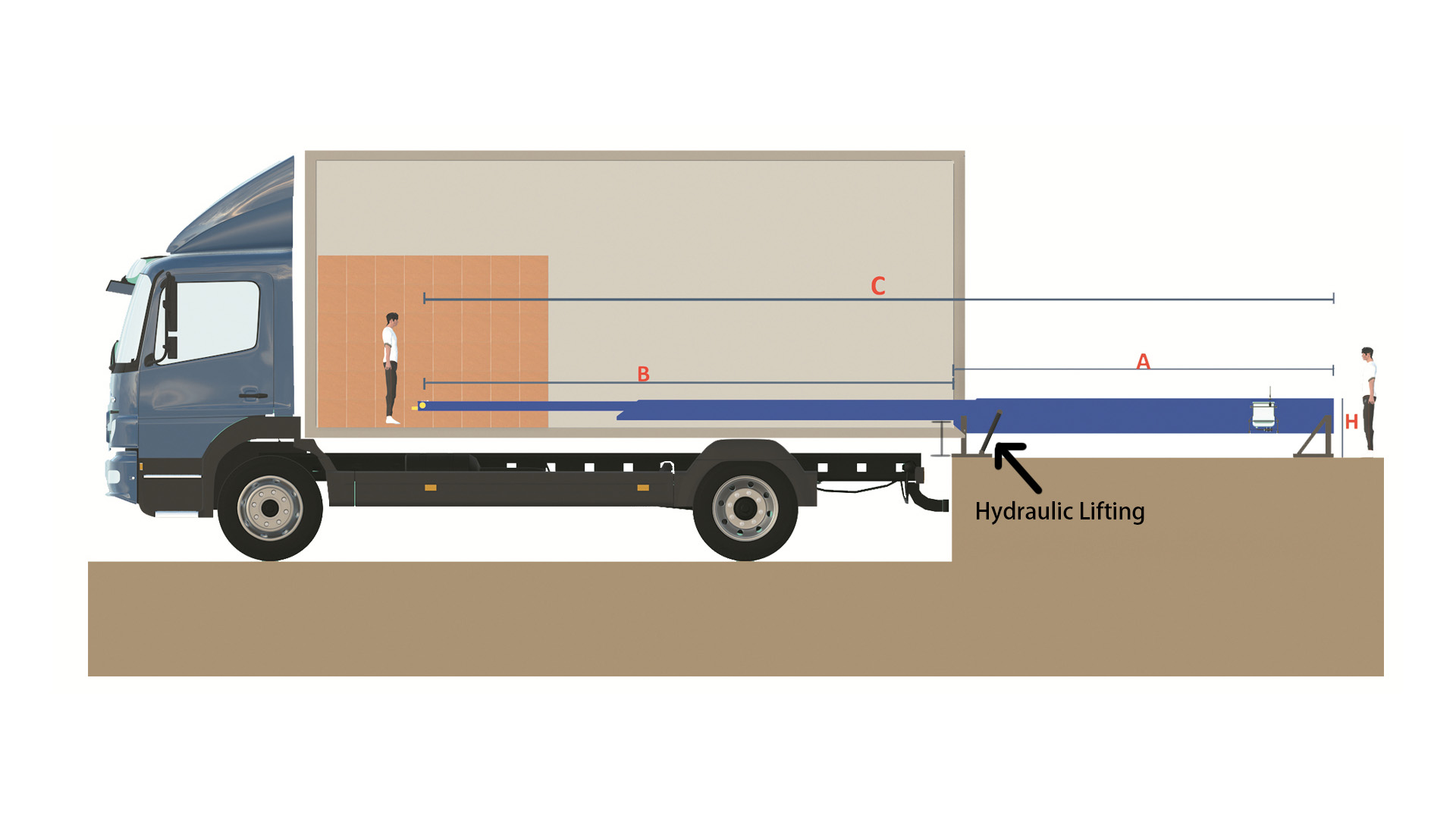

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 6000 | 16000 | 22000 |

| 7000 | 17000 | 24000 |

Applicable Goods

Flat-bottomed Goods

Bagged Goods

Load Capacity

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 5000 | 9000 | 14000 |

| 6000 | 12000 | 18000 |

| 7000 | 14000 | 21000 |

| 8000 | 17000 | 25000 |

Applicable Goods

Flat-bottomed Goods

Bagged Goods

Load Capacity

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 3000 | 2000 | 5000 |

| 4000 | 3000 | 7000 |

| 5000 | 4000 | 9000 |

| 6000 | 5000 | 11000 |

| 7000 | 6000 | 13000 |

Applicable Goods

Flat-bottomed Goods

Bagged Goods