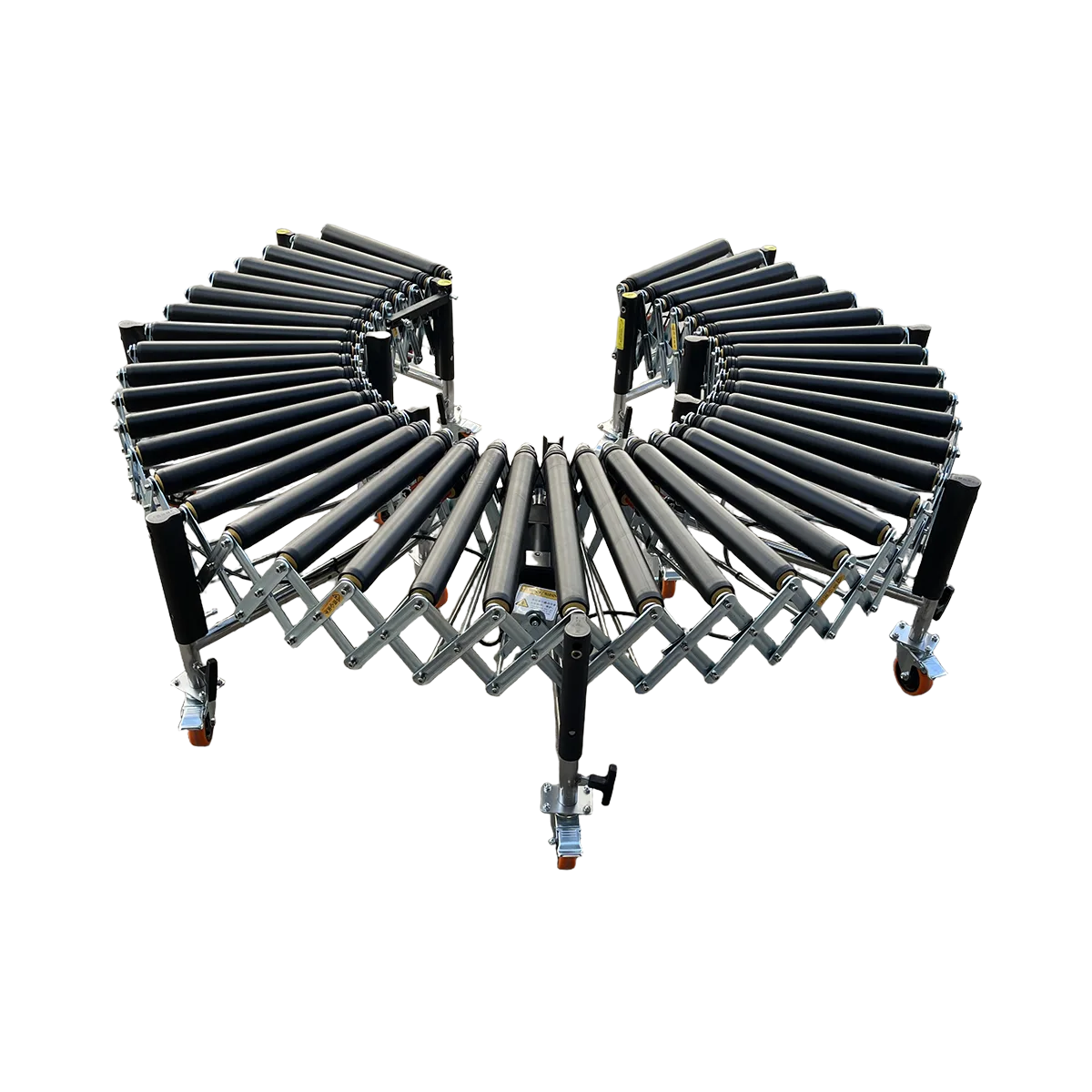

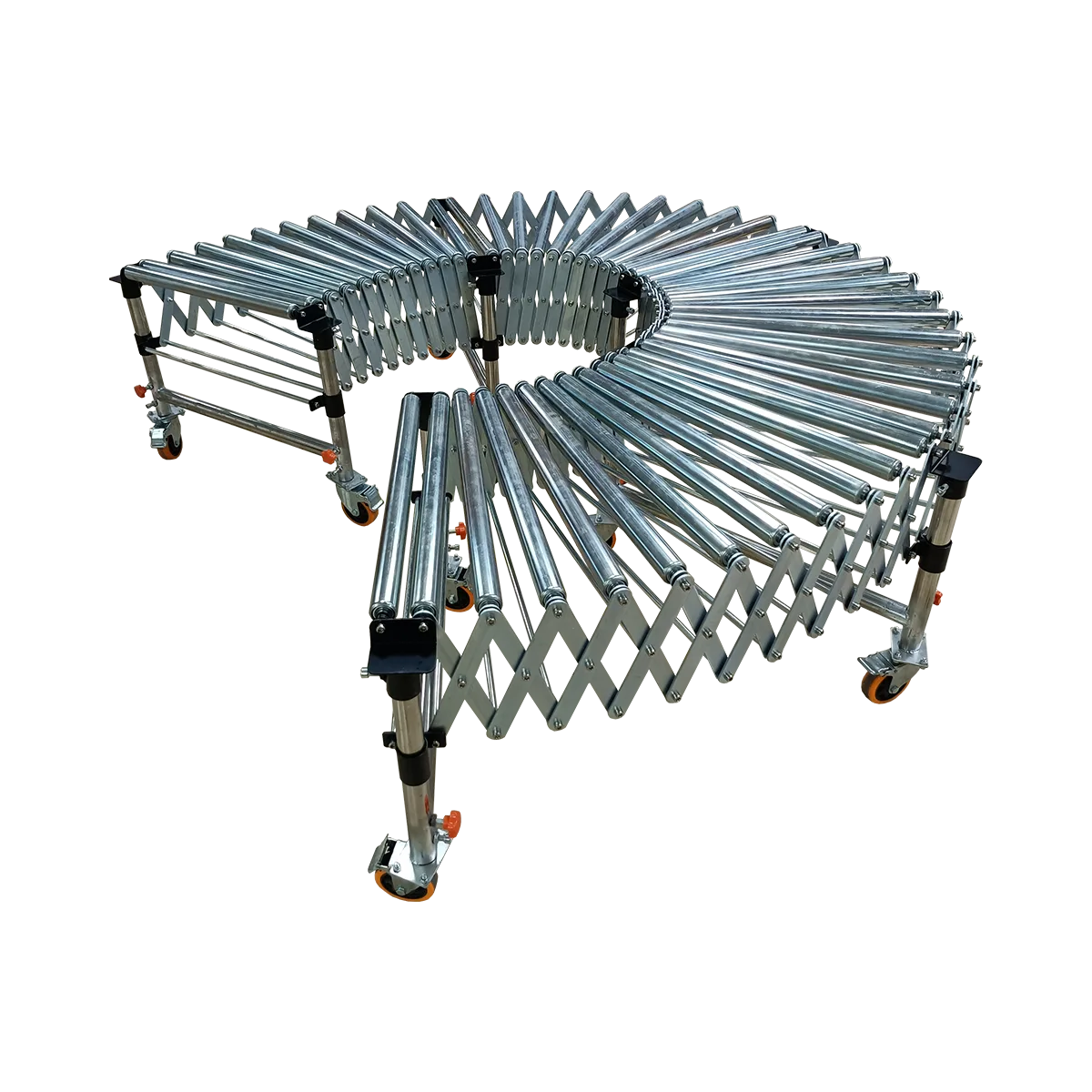

Expandable Roller Conveyor

Streamline your material handling operations with expandable roller conveyors – the versatile solution for flexible logistics.

Related Products

- Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

- Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

- Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

- Gravity Roller Conveyor – Roller Diameter 50 mm – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Gravity Roller Conveyor – Roller Diameter 38 mm – 1700 mm/SectionCollapsed Length

485 mm

Extended Length1700 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

Streamline your material handling operations with expandable roller conveyors – the versatile solution for flexible logistics. These adaptable conveyor systems can extend to multiple times their contracted length, offering exceptional space efficiency and mobility for warehouses, distribution centers, and loading areas. With their adjustable length and height, expandable gravity roller conveyors and powered variants provide cost-effective solutions for temporary or permanent material transport needs, helping businesses optimize workflow while minimizing floor space requirements.

What Makes Expandable Roller Conveyors Essential for Modern Logistics

Flexible expandable roller conveyors represent a significant advancement in material handling technology. These systems utilize an ingenious scissor-like frame design that allows them to compact for storage and expand during operation. This functionality makes them particularly valuable for:

- Operations with fluctuating space requirements

- Temporary loading/unloading setups

- Facilities needing to reconfigure workflow frequently

- Businesses seeking to maximize storage efficiency

- Mobile operations requiring portable conveyor solutions

The ability to adapt length on demand not only saves valuable floor space but also reduces the need for multiple fixed-length conveyor sections. When not in use, these systems can be compacted and stored with minimal footprint, then quickly deployed when needed.

Types of Expandable Roller Conveyors

When selecting an expandable roller conveyor, you’ll typically choose between gravity and powered variants. Each serves specific operational needs:

Gravity Expandable Roller Conveyors

Gravity Roller Conveyor systems operate without motors, using gravity or manual push to move goods. These cost-effective solutions are ideal for operations where power access is limited or unnecessary.

Key Specifications:

- 50mm Roller Diameter Model:Contracted length: 525mm

- Expanded length: 1500mm

- Expansion ratio: 1:3

- Load capacity: 80 kg/m

- 38mm Roller Diameter Model:Contracted length: 485mm

- Expanded length: 1700mm

- Expansion ratio: 1:3

- Load capacity: 50 kg/m

Gravity units require a slight incline (typically 2-5 degrees) for optimal performance or can be used horizontally with manual assistance. They feature adjustable height legs with locking casters, making them perfect for temporary setups and flexible operations.

Powered Expandable Roller Conveyors

For operations requiring automated movement regardless of incline, Powered Roller Conveyor systems offer motorized solutions with speed control capabilities.

| Specifications | O-type Belt Drive (1500mm/section) | Multi-wedge Belt Drive (2000mm/section) | Multi-wedge Belt Drive (3000mm/section) |

| Contracted Length | 525 mm | 700 mm | 1050 mm |

| Expanded Length | 1500 mm | 2000 mm | 3000 mm |

| Expansion Ratio | 1:3 | 2:3 | 1:3 |

| Speed | 0-40 m/min | 0-40 m/min | 0-40 m/min |

| Load Capacity | 80 kg/m | 100 kg/m | 80 kg/m |

| Width Options | 500/600/800 mm | 500/600/800 mm | 500/600/800 mm |

Powered expandable conveyors feature forward/reverse operation, variable speed control, and emergency stop functionality, making them suitable for more demanding applications while maintaining the space-saving benefits of expandability.

For applications requiring specialized surface types, Powered Rubber Roller Conveyor variants feature PVC-coated rollers that provide better grip for soft-packaged goods.

Applications and Suitable Environments

Expandable roller conveyors excel in numerous environments where flexibility is paramount:

Warehousing and Distribution

- Package and parcel handling between workstations

- Connecting sorting areas to loading docks

- Temporary overflow handling during peak seasons

- Reconfigurable picking lines

Loading/Unloading Operations

- Truck and container loading/unloading

- Extending from fixed conveyor systems into vehicles

- Creating temporary loading lanes

- Bridging gaps in existing material flow

Retail and E-commerce

- Seasonal processing requirements

- Backroom to sales floor merchandise movement

- Online order fulfillment operations

- Stockroom organization and inventory management

Suitable Cargo Types

Expandable gravity roller conveyors and their powered counterparts are designed to handle a wide range of items:

- ✓ Cardboard boxes and packaging

- ✓ Plastic containers and totes

- ✓ Small equipment and components

- ✓ Parcels and mail packages

- ✓ Flat-bottomed goods

- ✓ Light to medium-weight materials

For particularly soft or irregularly-shaped items, consider alternatives like Powered Rubber Roller Conveyor.

Key Considerations When Choosing an Expandable Roller Conveyor

When selecting the right flexible expandable roller conveyor for your operation, evaluate these critical factors:

- Required Length Range: Determine both the minimum and maximum lengths needed for your application. Consider the 1:3 expansion ratio of most roller conveyors when planning.

- Load Requirements: Assess the weight of your typical items and ensure the conveyor’s load capacity (50-100 kg/m depending on model) adequately supports your needs.

- Powered vs. Gravity: For horizontal transport or precise speed control, powered models offer advantages. For simple inclined movement or budget concerns, gravity systems may suffice.

- Roller Diameter: Larger diameter rollers (50mm) provide better support for heavier items, while smaller rollers (38mm) may offer more contact points for lighter goods.

- Mobility Needs: Consider whether the conveyor will remain stationary or require frequent repositioning. All models include casters, but weight varies between types.

For operations requiring height differentials between floor level and vehicles, consider complementing your expandable conveyor with a Hydraulic Conveyor for a complete loading/unloading solution.

Installation and Maintenance

Expandable roller conveyors are designed for simplified setup and minimal maintenance:

Installation Basics

- Ensure a flat, stable floor surface

- Adjust leg heights to achieve desired slope (for gravity models) or horizontal alignment

- Lock casters once positioned

- For powered models, connect to appropriate power supply (typically 380V or 220V)

- When connecting multiple sections, ensure proper alignment at junction points

Maintenance Requirements

- Daily Check: Visual inspection of rollers and framework

- Weekly Maintenance: Verify free rotation of all rollers and clean surfaces

- Monthly Service: Check and tighten connections, lubricate bearings

- Quarterly Inspection: Examine drive belts (for powered models) and adjust tension as needed

With proper care, expandable conveyor frames typically last 5-10 years under normal usage conditions. Drive belts on powered models may require replacement every 6-12 months depending on usage intensity.

Expandable Roller Conveyor FAQs

What is the weight capacity of expandable roller conveyors?

Load capacity ranges from 50 kg/m for 38mm roller models to 100 kg/m for multi-wedge belt drive powered models, with most standard options supporting 80 kg/m.

How much slope is needed for gravity expandable roller conveyors?

Typically 2-5 degrees of incline provides optimal movement, though this varies based on cargo weight, packaging material, and roller condition.

Can expandable roller conveyors be used outdoors?

Standard models are designed primarily for indoor use, but stainless steel options are available for temporary outdoor applications with proper maintenance and protection from elements.

How many workers are needed to operate an expandable conveyor system?

Most operations require a minimum of two workers – one at the loading end to place items and one at the unloading end to receive them.

What is the lifespan of an expandable roller conveyor?

With proper maintenance, frames typically last 5-10 years. For powered models, drive belts usually require replacement every 6-12 months depending on usage intensity.

Combining Expandable Conveyors with Other Material Handling Solutions

For comprehensive logistics solutions, expandable roller conveyors can be effectively integrated with other systems:

Complementary Equipment Options

The modular nature of expandable conveyors makes them ideal for integration with:

- Telescopic Conveyor systems for deep-reach applications into containers and trucks

- Fixed powered conveyor lines in distribution centers

- Hydraulic Conveyor units for managing height differentials

- Picking stations and packing tables in fulfillment operations

- Sorting systems in distribution operations

Many facilities use expandable sections strategically at transition points, such as between fixed conveyor systems and loading areas, or as temporary extensions during peak capacity periods.

Conclusion: Maximizing Efficiency with Expandable Conveyor Solutions

Expandable roller conveyors represent an intelligent investment for operations seeking to maximize space efficiency while maintaining material handling flexibility. Whether you choose a gravity expandable roller conveyor for economical transport or a powered version for more demanding applications, these systems deliver exceptional value through their adaptable design.

By carefully matching your specific operational requirements with the appropriate expandable conveyor specifications, you can significantly enhance workflow efficiency while reducing space requirements and equipment costs. The ability to contract these systems when not in use further extends their practical value, especially in facilities where floor space comes at a premium.

For businesses experiencing seasonal fluctuations, frequent layout changes, or those simply seeking to optimize their material handling capabilities, flexible expandable roller conveyors provide a versatile solution that adapts to your changing needs rather than forcing your operation to adapt around fixed equipment.

Table of Contents

Recent Posts

Optimize hardware store logistics with the right building supply conveyor systems. Our guide to tool distribution systems enhances retail warehouse automation for efficient operations.

Optimize your medical supply logistics with efficient gravity conveyor systems. Learn how to safely handle healthcare products while improving your hospital supply chain operations.

Discover how a sports equipment conveyor system can streamline your athletic gear logistics. Flexible conveyor solutions for all shapes and sizes of sporting goods.