Powered Roller Conveyor vs. Gravity Roller Conveyor: Which One to Choose?

Comparing powered roller conveyor vs. gravity roller conveyor systems? Discover which conveyor technology best fits your warehouse needs, budget, and operational goals.

Related Products

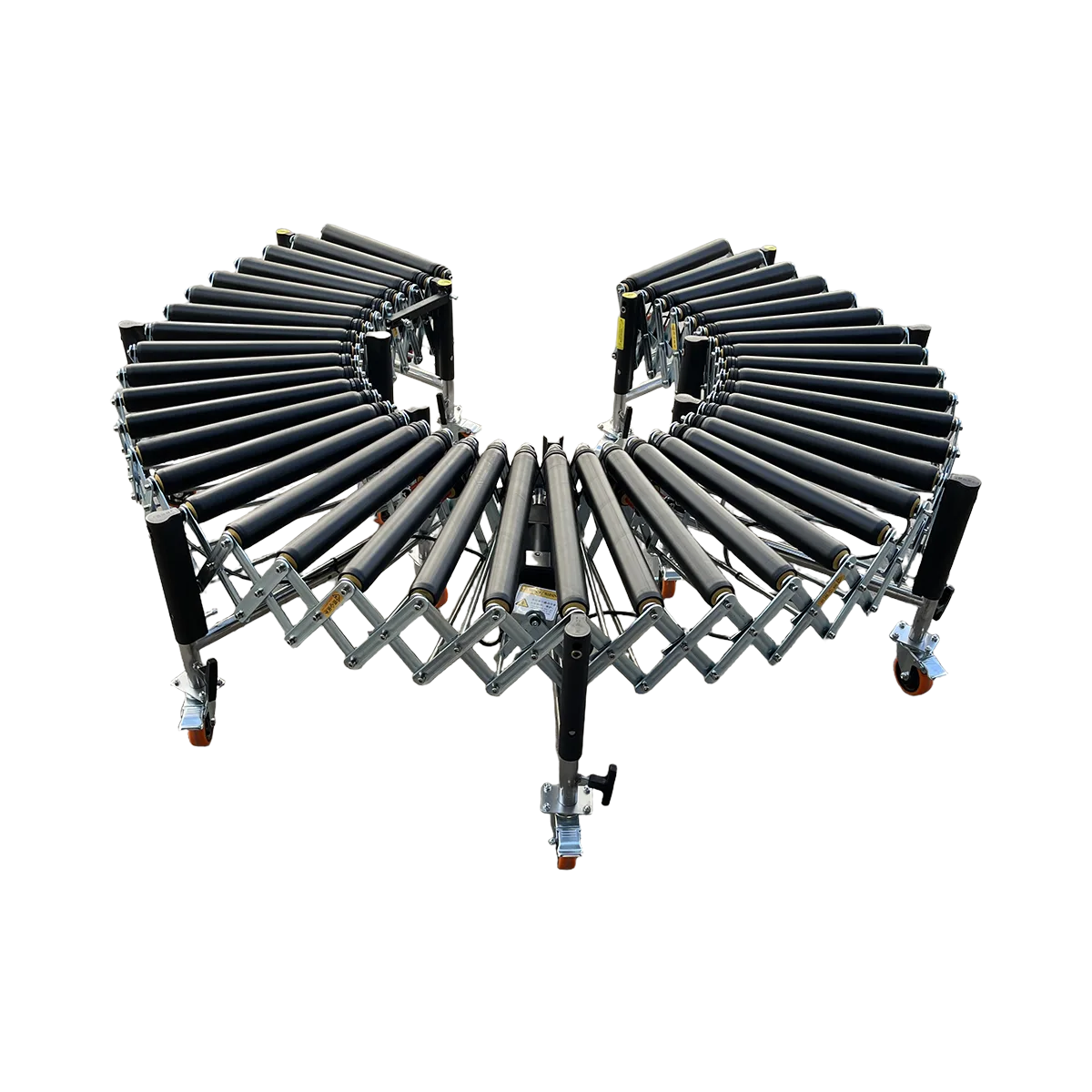

- Powered Rubber Roller Conveyor – Multi-wedge Belt Driven – 1100 mm/SectionCollapsed Length

560 mm

Extended Length1100 mm

Load Capacity120 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Powered Roller Conveyor – O-shaped Belt Driven – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

- Powered Roller Conveyor – Multi-wedge Belt Driven – 2000 mm/SectionCollapsed Length

700 mm

Extended Length2000 mm

Load Capacity100 kg/m

Applicable GoodsFlat-bottomed Goods

- Powered Roller Conveyor – Multi-wedge Belt Driven – 3000 mm/SectionCollapsed Length

1050 mm

Extended Length3000 mm

Load Capacity80 kg/m

Applicable GoodsFlat-bottomed Goods

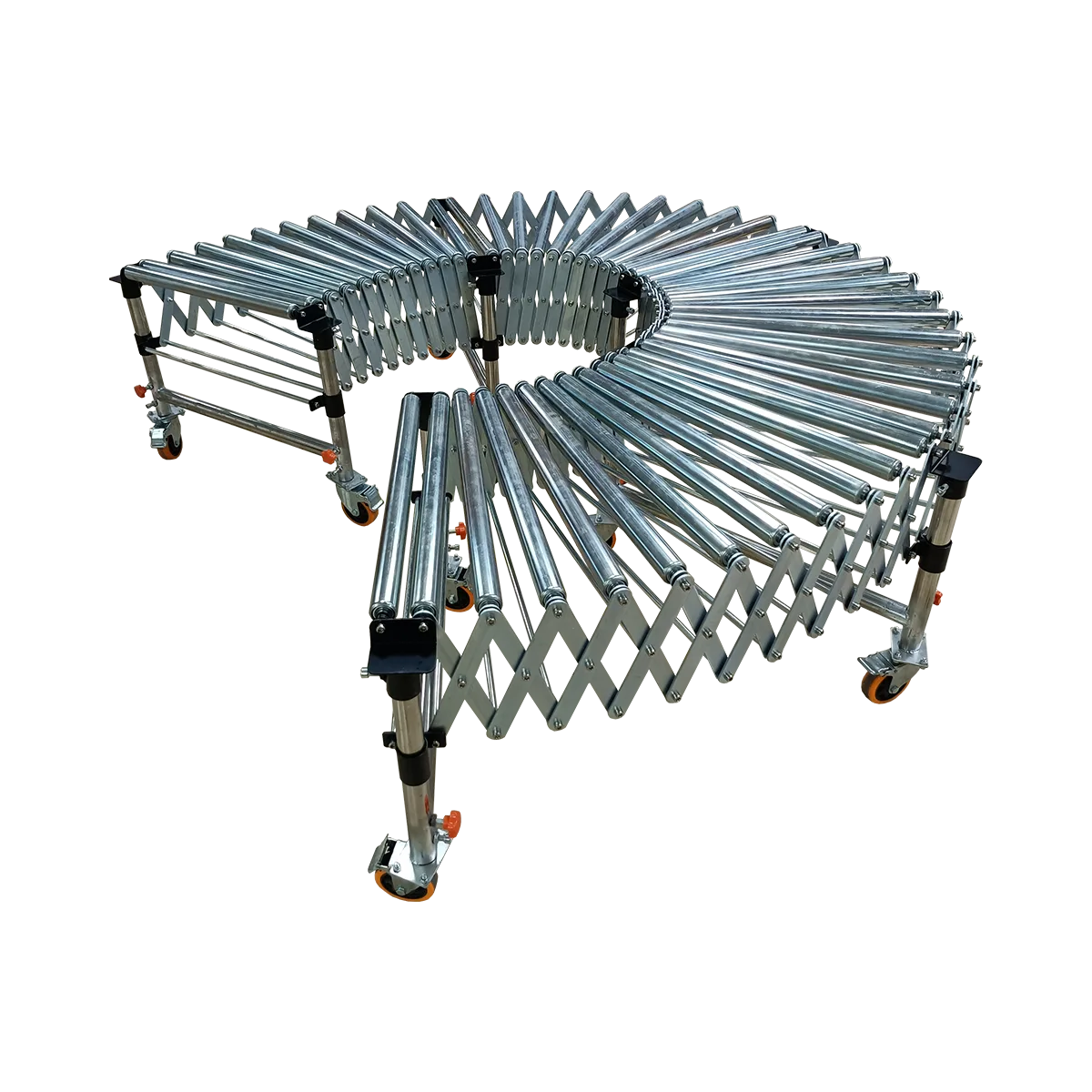

- Gravity Roller Conveyor – Roller Diameter 50 mm – 1500 mm/SectionCollapsed Length

525 mm

Extended Length1500 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

- Gravity Roller Conveyor – Roller Diameter 38 mm – 1700 mm/SectionCollapsed Length

485 mm

Extended Length1700 mm

Load Capacity50 kg/m

Applicable GoodsFlat-bottomed Goods

Bagged Goods

When designing an efficient warehouse or distribution center, choosing the right conveyor systems can significantly impact your operational efficiency and bottom line. Two of the most common options – the powered roller conveyor and the gravity roller conveyor – serve similar purposes but operate on fundamentally different principles. Each offers distinct advantages for specific applications, and understanding these differences is crucial for making an informed decision that aligns with your logistics needs, space constraints, and budget considerations.

The Basics: What is a Gravity Roller Conveyor?

At its core, a gravity roller conveyor is an elegantly simple material handling solution that requires no motors or electrical connections. As the name suggests, it uses gravity as its driving force, with products moving along an inclined surface of freely rotating rollers.

How It Works

Gravity roller conveyors rely on a slight slope (typically 2-5 degrees) to create momentum. As packages are placed on the higher end, gravity pulls them downward, and the rollers rotate to facilitate smooth movement with minimal friction. This elegantly simple design makes it one of the most reliable components in warehouse automation systems.

Pros: The Simple Solution

- No Power Required: Functions completely without electricity, reducing energy costs and allowing placement anywhere

- Low Initial Investment: Significantly more affordable than powered alternatives

- Minimal Maintenance: Fewer moving parts means fewer things that can break or require servicing

- Reliability: Continues to function during power outages

- Flexibility: Easily expanded or reconfigured as needed

- Quiet Operation: Creates minimal noise in the workplace

Cons: The Limitations

- Requires Height Difference: Needs an incline to function, limiting installation options

- Limited Speed Control: Product weight affects speed, making consistent flow challenging

- Distance Limitations: Not ideal for long horizontal distances

- Manual Assistance Sometimes Needed: May require pushing to start movement on gentle slopes

Naili’s Gravity Roller Conveyors

Naili offers two primary types of gravity roller conveyors, differentiated by their roller diameter and capacity:

| Feature | 38mm Model | 50mm Model |

| Total Length (Extended) | 1700mm per section | 1500mm per section |

| Load Capacity | 50 kg/m | 50 kg/m |

| Best For | Lighter packages, longer sections | Heavier loads, more stability |

| Roller Spacing | 150mm | 110mm |

| Weight | Lighter (20-30kg per section) | Heavier (26-39kg per section) |

Both models feature a 1:3 extension ratio, adjustable height supports, and quality construction with either galvanized or stainless steel options for different environments.

The Next Level: What is a Powered Roller Conveyor?

A powered roller conveyor uses motorized rollers to transport goods horizontally or even uphill, offering precise control over product movement regardless of weight or incline. This active transport capability opens up many more possibilities for complex logistics equipment configurations.

How It Works

Powered roller conveyors use electric motors connected to drive systems that rotate the rollers at controlled speeds. Naili offers two primary drive mechanisms:

- O-belt Drive: Individual O-shaped belts connect adjacent rollers, transferring power from a central motor. This system is simple and cost-effective.

- Multi-wedge Belt Drive: A single multi-ribbed belt transmits power to multiple rollers simultaneously, offering higher torque and more consistent drive power.

Pros: The Powerful Advantage

- Speed Control: Adjustable conveyor speed (up to 40 m/min) to match your operational pace

- Horizontal Transport: No incline required, maximizing space utilization

- Bidirectional Operation: Can move products forward or backward as needed

- Consistent Performance: Maintains the same speed regardless of package weight

- Enhanced Throughput: Higher processing capacity than gravity systems

- Better Integration: Easily connects with other automated systems

Cons: The Trade-offs

- Higher Initial Cost: More expensive to purchase and install

- Requires Power: Dependent on electrical supply

- More Maintenance: Additional mechanical and electrical components require regular service

- Noise Considerations: Motors generate some operational noise

- Technical Support: May require more specialized knowledge for repairs

Naili’s Powered Roller Conveyors

Naili offers several powered roller conveyor configurations to meet different operational needs:

| Feature | O-belt Drive (1500mm) | Multi-wedge Belt (2000mm) | Multi-wedge Belt (3000mm) |

| Extension Ratio | 1:3 (525mm to 1500mm) | 2:3 (700mm to 2000mm) | 1:3 (1050mm to 3000mm) |

| Load Capacity | 80 kg/m | 100 kg/m | 80 kg/m |

| Best For | General applications, economy | Heavy-duty applications | Longer distance transport |

| Drive System | O-belt (one per 1.5m) | Multi-wedge belt (one per 2m) | Multi-wedge belt (one per 2m) |

| Weight | Lighter (31-41kg per section) | Medium | Heavier (60-80kg per section) |

All powered models include speed control (0-40 m/min), bidirectional operation, and emergency stop features for safe operation.

Head-to-Head Comparison: A Decision Matrix

When deciding between gravity and powered roller conveyors, consider these key factors:

Cost Considerations

Initial Investment:

- Gravity systems cost 30-50% less upfront than comparable powered systems

- Installation costs are lower for gravity systems due to simpler setup requirements

Operating Expenses:

- Gravity systems have zero energy consumption

- Powered systems consume electricity (typically 0.75-2.2kW per system)

- Maintenance costs are higher for powered systems due to motors, belts, and electrical components

Control & Performance

Speed Management:

- Gravity: Limited control, product weight affects speed

- Powered: Precise speed control via variable frequency drive (0-40 m/min)

Directional Control:

- Gravity: One-way movement only, downward slope

- Powered: Bidirectional capability, can reverse flow direction

Consistency:

- Gravity: Variable speed based on product weight and friction

- Powered: Consistent speed regardless of load (within capacity limits)

Application Suitability

Ideal Scenarios for Gravity Roller Conveyors:

- Short-distance transport with natural height differences

- Connecting workstations at different elevations

- Temporary or mobile installations

- Low-speed applications where precise timing isn’t critical

- Operations with unreliable power supply or energy-saving initiatives

- Budget-conscious projects with simple material flow

Ideal Scenarios for Powered Roller Conveyors:

- Long horizontal distances where gravity alone is insufficient

- Applications requiring specific, controlled speeds

- High-volume operations needing consistent throughput

- Integration with other automated systems

- Situations where space constraints prohibit sloped installations

- Operations requiring bidirectional product movement

Making the Right Choice for Your Business

When to Choose Gravity

Consider a gravity roller conveyor when:

- You have natural elevation changes you can leverage

- Your budget is limited and initial cost is a primary concern

- Products being transported are sturdy and consistent in weight

- Electricity availability is limited or costly

- You need a simple, reliable system with minimal maintenance

- Your operation is low to medium volume (under 200 packages per hour)

- The system needs to be frequently reconfigured or moved

When to Choose Powered

Opt for a powered roller conveyor when:

- Your facility has primarily flat floors with minimal elevation changes

- Consistent product flow rate is critical to your operation

- You handle varying package weights that would move inconsistently on gravity systems

- Your operation requires long horizontal transport distances

- You need to integrate with other automated systems

- Your facility handles high volumes (200+ packages per hour)

- Energy costs are reasonable compared to labor savings

For specialized applications like transporting soft packages or bags, consider Naili’s Powered Rubber Roller Conveyor, which features PVC-coated rollers that provide better grip for non-rigid items.

Conclusion: Finding Your Perfect Conveyor Match at Naili Conveyor

The choice between powered and gravity systems ultimately depends on your specific operational needs, facility layout, and budget constraints. Many facilities benefit from implementing a hybrid approach, using gravity systems where natural elevation changes exist and powered systems where horizontal movement or precise control is required.

Naili’s extensive range of both powered roller conveyor and gravity roller conveyor solutions ensures that you can find the perfect match for your material handling requirements. Both systems are designed with modular connectivity, allowing you to expand your telescopic conveyor system as your business grows or your needs evolve.

Remember that the right conveyor isn’t necessarily the most advanced or expensive option—it’s the one that most efficiently moves your products while maximizing your return on investment.

Frequently Asked Questions

Can gravity and powered roller conveyors be connected together?

Yes, they can be connected to create hybrid systems that leverage the advantages of both. This is commonly done to minimize energy usage while maintaining flow efficiency.

How much slope is needed for a gravity roller conveyor to work effectively?

Typically 2-5 degrees is optimal, with the exact angle depending on package weight and surface characteristics. Lighter packages require steeper slopes.

What maintenance is required for each type?

Gravity systems mainly need occasional cleaning and bearing checks. Powered systems require additional motor maintenance, drive belt inspections, and electrical system checks.

Which system is better for fragile items?

Powered roller conveyors often provide better control for fragile items since their speed remains consistent regardless of package weight, preventing unexpected acceleration.

Can these conveyors be used outdoors?

Both types can be used outdoors with proper specifications. For outdoor use, select galvanized or stainless steel components and consider weather protection for powered systems’ electrical components.

Table of Contents

Recent Posts

Optimize hardware store logistics with the right building supply conveyor systems. Our guide to tool distribution systems enhances retail warehouse automation for efficient operations.

Optimize your medical supply logistics with efficient gravity conveyor systems. Learn how to safely handle healthcare products while improving your hospital supply chain operations.

Discover how a sports equipment conveyor system can streamline your athletic gear logistics. Flexible conveyor solutions for all shapes and sizes of sporting goods.