Loading/Unloading Conveyor Manufacturer

Home > Loading/Unloading Conveyor

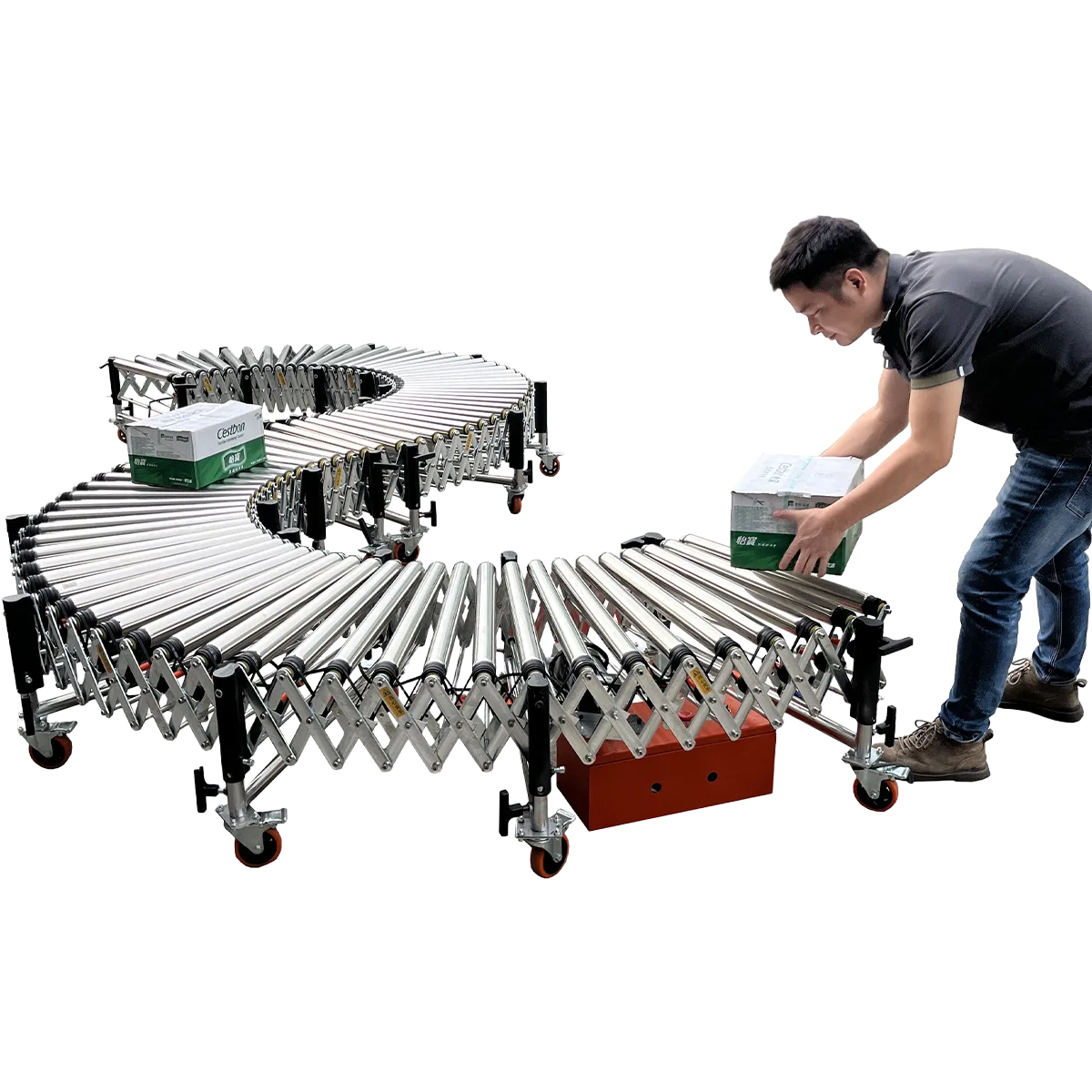

Loading and unloading conveyors represent material handling’s ultimate evolution—ingeniously engineered systems transforming laborious manual processes into smooth automated workflows.

Our Loading/Unloading Conveyor Products

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 6000 | 16000 | 22000 |

| 7000 | 17000 | 24000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 5000 | 9000 | 14000 |

| 6000 | 12000 | 18000 |

| 7000 | 14000 | 21000 |

| 8000 | 17000 | 25000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 4000 | 5000 | 9000 |

| 5000 | 7000 | 12000 |

| 6000 | 8000 | 14000 |

| 6000 | 8500 | 14500 |

| 7000 | 9000 | 16000 |

| 7000 | 9500 | 16500 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 3000 | 2000 | 5000 |

| 4000 | 3000 | 7000 |

| 5000 | 4000 | 9000 |

| 6000 | 5000 | 11000 |

| 7000 | 6000 | 13000 |

Flat-bottomed Goods

Bagged Goods

7900 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

7000 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

5400 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

3700 mm

50 kg/m

Flat-bottomed Goods

Bagged Goods

560 mm

1100 mm

120 kg/m

Flat-bottomed Goods

Bagged Goods

525 mm

1500 mm

80 kg/m

Flat-bottomed Goods

700 mm

2000 mm

100 kg/m

Flat-bottomed Goods

1050 mm

3000 mm

80 kg/m

Flat-bottomed Goods

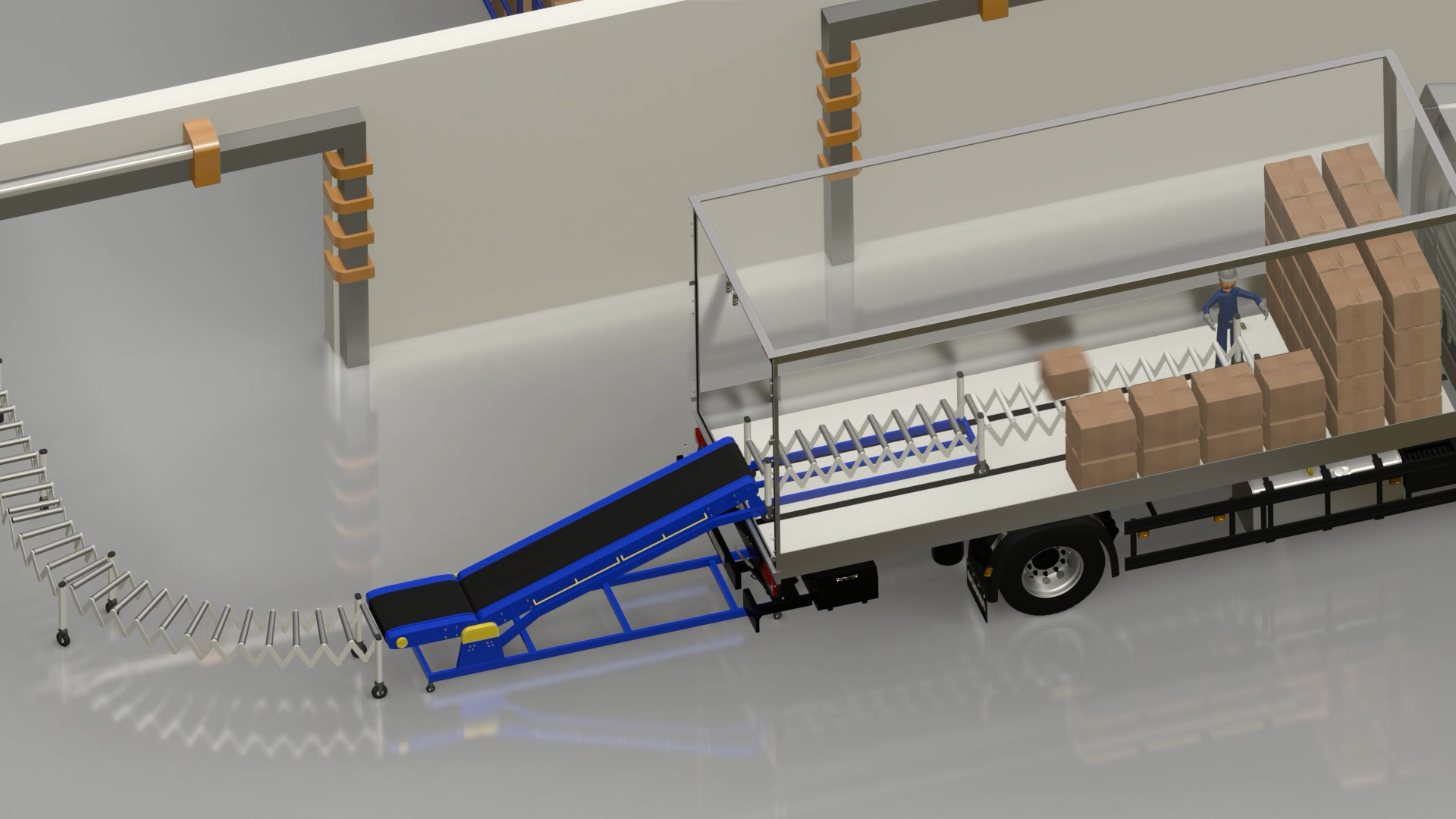

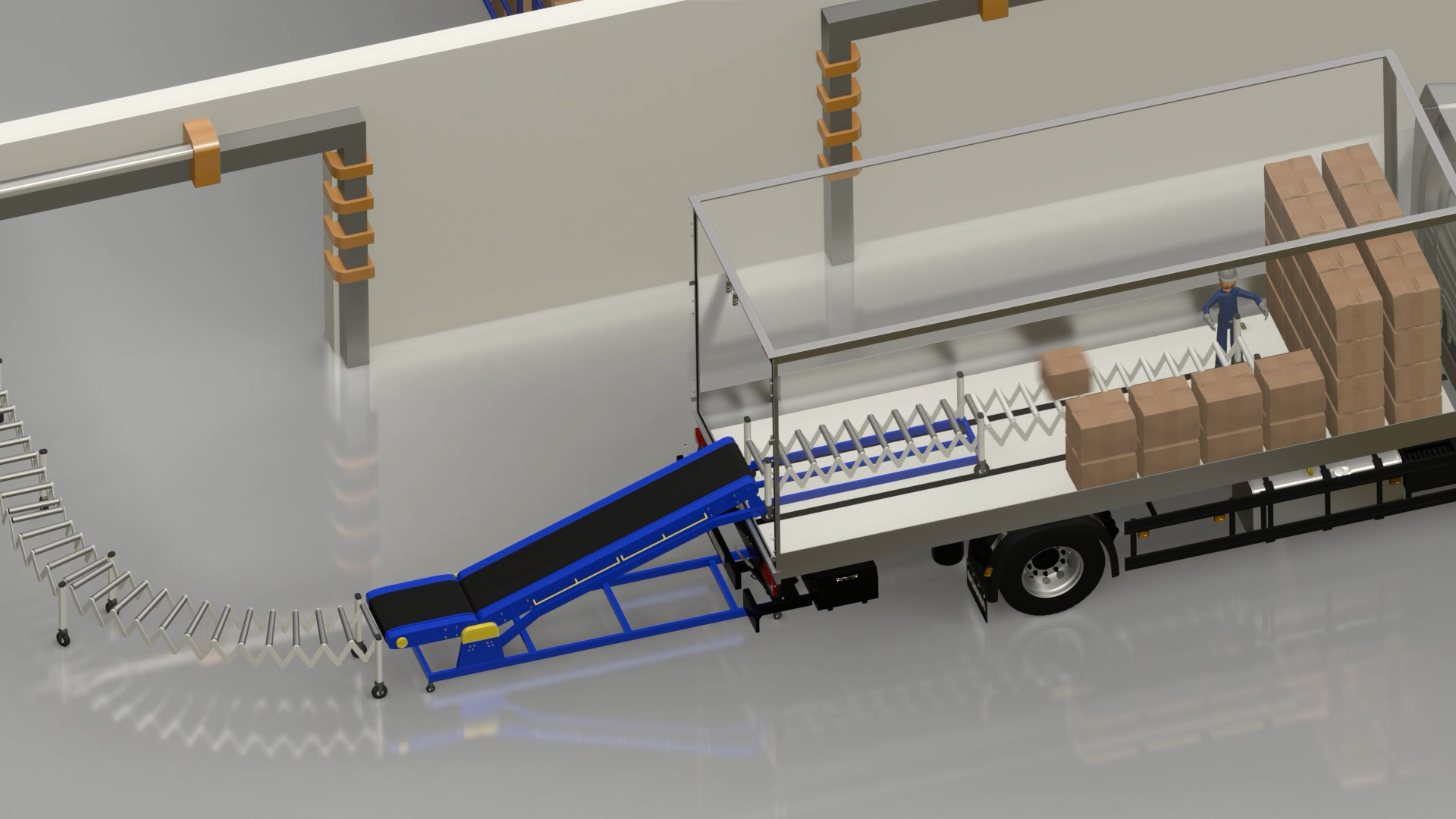

Picture towering truck trailers perfectly aligned with your loading dock while products zoom effortlessly across dynamic bridges spanning warehouse floor to vehicle interior! Loading and unloading conveyors represent material handling’s ultimate evolution—ingeniously engineered systems transforming laborious manual processes into smooth automated workflows. Unlike traditional fixed equipment, these dynamic marvels stretch dramatically toward delivery vehicles then collapse compactly when unused, maximizing precious facility space. Naili’s comprehensive loading and unloading conveyor lineup includes hydraulic–powered incline units, multi-wedge belt driven rollers, O-shaped belt systems and telescopic conveyors stretching up to 25 meters from compact frames! Each design addresses unique operational challenges through thoughtful engineering focusing toward efficiency, durability, worker safety and adaptability across industries. Facility managers worldwide report dramatic productivity improvements, substantial labor savings and significant injury reductions following implementation within loading dock environments.

Hydraulic Loading and Unloading Conveyors: Conquering Elevation Challenges

Standard conveyors struggle with height differences but hydraulic loading and unloading systems laugh at elevation challenges! These impressive machines create smooth transitions between varying heights with push-button simplicity.

Power-Packed Performance

Naili hydraulic loading and unloading conveyors deliver extraordinary capabilities through robust construction and precision engineering. Available in multiple configurations addressing diverse facility requirements:

| Model | Length | Load Capacity | Key Advantages |

| Large | 7900mm | 80 kg/m | Extended reach for major loading operations |

| Medium | 7000mm | 80 kg/m | Perfect balance between reach and maneuverability |

| Small | 4000mm | 80 kg/m | Exceptional mobility within tight spaces |

| Micro | 3700mm | 50 kg/m | Ultra-compact design for specialized applications |

These versatile loading and unloading systems handle challenging elevation changes without complicated permanent installations! Operators appreciate simplified loading procedures while management celebrates productivity improvements exceeding 40% following implementation.

Precision Hydraulic Control

Loading dock operations demand perfect positioning capabilities accounting for vehicle height variations. Naili hydraulic loading and unloading conveyor systems feature:

- Powerful hydraulic cylinders delivering up to 5 tons thrust capacity

- Precision control systems allowing exact positioning adjustments

- Heavy-duty components withstanding punishing operational environments

- Variable speed drives maintaining perfect product flow rates regardless of angle

- Robust construction supporting substantial loads throughout extended reaches

Warehouse supervisors report dramatic efficiency improvements following installation! Products flow smoothly from receiving areas directly into trucks without intermediate handling steps—eliminating wasteful touches throughout distribution processes.

Beyond Basic Transportation

Modern hydraulic loading and unloading conveyors transform loading processes through intelligent design features addressing real-world operational challenges:

- Anti-slip belting prevents package sliding even during steep incline operations

- Integrated control panels include forward/reverse/emergency functions ensuring operator safety

- Heavy-duty casters with full brake mechanisms provide positional stability during operation

- Adjustable speeds accommodate various product types without damage concerns

- Compatibility with gravity extensions maximizes total system reach capabilities

These thoughtful engineering elements combine creating remarkably effective loading solutions adaptable across virtually unlimited application possibilities. Their versatility proves particularly valuable within operations handling diverse product sizes simultaneously.

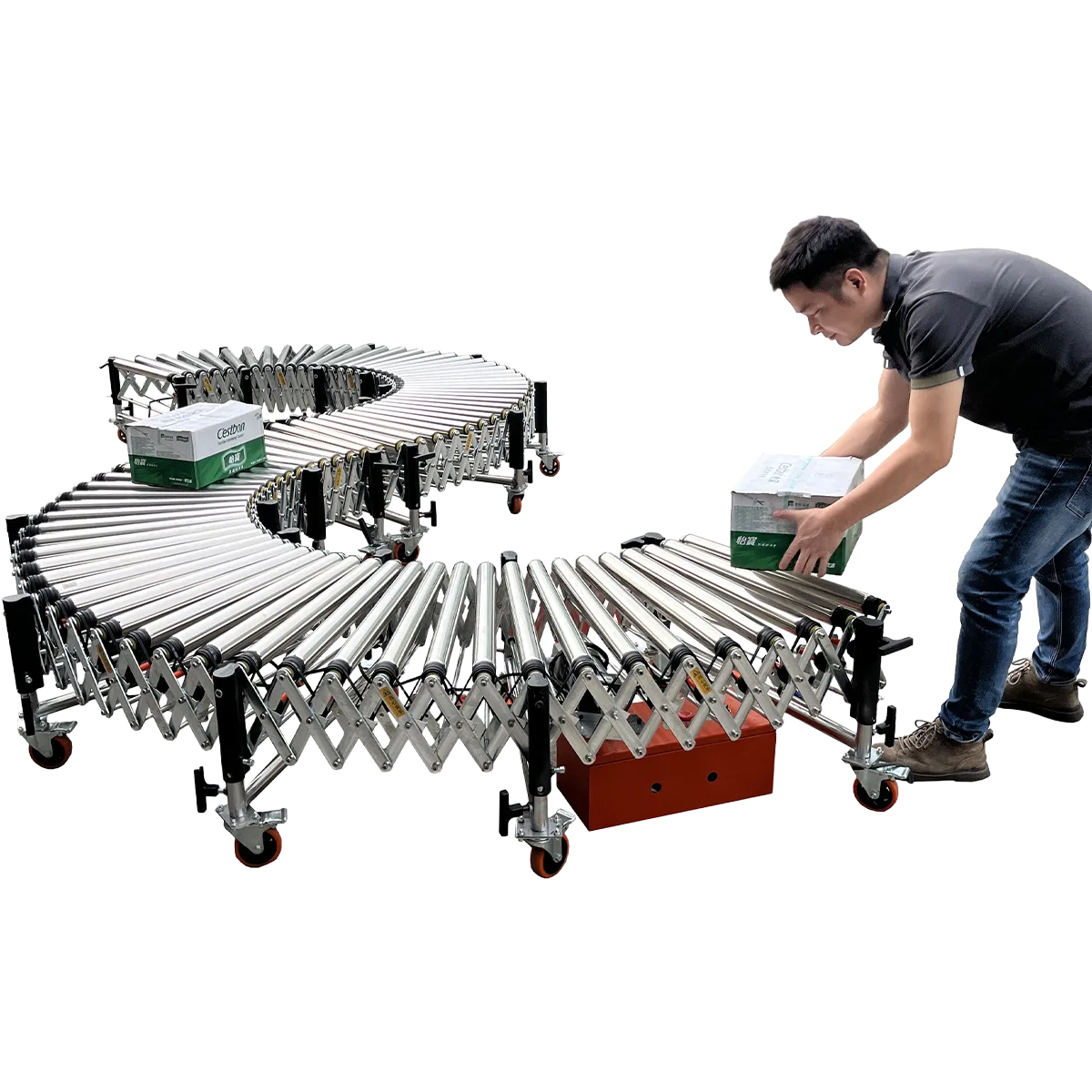

Powered Roller Loading and Unloading Conveyor Technology

When gravity alone proves insufficient, powered roller loading and unloading conveyors deliver consistent movement regardless of weight distribution, package characteristics or directional requirements.

Multi-Wedge Belt Drive Loading and Unloading Systems

Naili’s multi-wedge belt driven loading and unloading conveyors represent mechanical engineering excellence through effective design. Their unique configuration provides numerous operational advantages:

- Consistent power delivery across all rollers ensuring smooth product movement

- Minimal maintenance requirements compared with traditional chain-driven alternatives

- Extended belt lifespans through reduced friction and improved tension distribution

- Quiet operation enhancing workplace communication capabilities

- Simplified cleaning procedures promoting sanitation within sensitive environments

Available in both 2-meter and 3-meter configurations, these versatile loading and unloading systems adapt beautifully across countless applications requiring controlled product movement regardless of weight distribution challenges. Their exceptional 1:3 extension ratio transforms 700mm collapsed units into impressive 2-meter transportation pathways when needed!

| Feature | 2-Meter Model | 3-Meter Model |

| Load Capacity | 100 kg/m | 80 kg/m |

| Speed | 40 m/min | 40 m/min |

| Extension Ratio | 2:3 | 1:3 |

| Collapsed Length | 700mm | 1050mm |

| Extended Length | 2000mm | 3000mm |

| Roller Count | 14 (standard section) | 10 (standard section) |

Operation managers particularly appreciate their exceptional durability within demanding environments! Robust construction featuring galvanized or stainless steel rollers maintains perfect alignment despite constant usage throughout multi-shift operations.

O-Shaped Belt Loading and Unloading Conveyor Technology

Some applications demand specialized handling characteristics addressing unique product requirements. Naili’s O-shaped belt driven roller loading and unloading conveyors deliver reliable performance through efficient design:

- Simplified maintenance through easily replaceable individual belts

- Superior tracking stability preventing belt wandering during operation

- Enhanced grip providing reliable movement for challenging materials

- Reduced vibration transmission protecting delicate products during transport

- Extended component lifespans through optimized power distribution

These specialized loading and unloading systems excel within operations handling irregular package shapes or potentially unstable items requiring additional movement stability. Their thoughtful design prevents product shifting during transportation while maintaining precise positioning throughout entire conveyor paths.

Facility engineers report exceptional reliability following installation! These durable loading and unloading conveyors frequently deliver years reliable service despite minimal maintenance attention—a particularly valuable characteristic within continuously operating distribution environments.

Rubber Roller Loading and Unloading Conveyor Systems

Delicate product handling requires specialized equipment preventing damage during transportation processes. Naili rubber roller loading and unloading conveyors provide gentle yet positive movement through thoughtfully engineered components:

- Cushioned product contact eliminating potential damage from hard surface impacts

- Enhanced friction coefficients preventing slippage during incline operations

- Superior noise reduction improving workplace communication capabilities

- Scratch prevention maintaining product appearance quality throughout handling

- Consistent movement control regardless of package surface characteristics

These specialized loading and unloading systems particularly excel within operations handling finished consumer goods requiring damage-free transportation before shipping. Their unique characteristics prove especially valuable when processing packaged items with glossy surface finishes potentially damaged through traditional handling methods.

Quality managers appreciate dramatic damage reduction metrics following implementation! Operations frequently report 70%+ decreases in product rejection rates traceable toward handling issues after transitioning toward rubber roller loading and unloading conveyor technology.

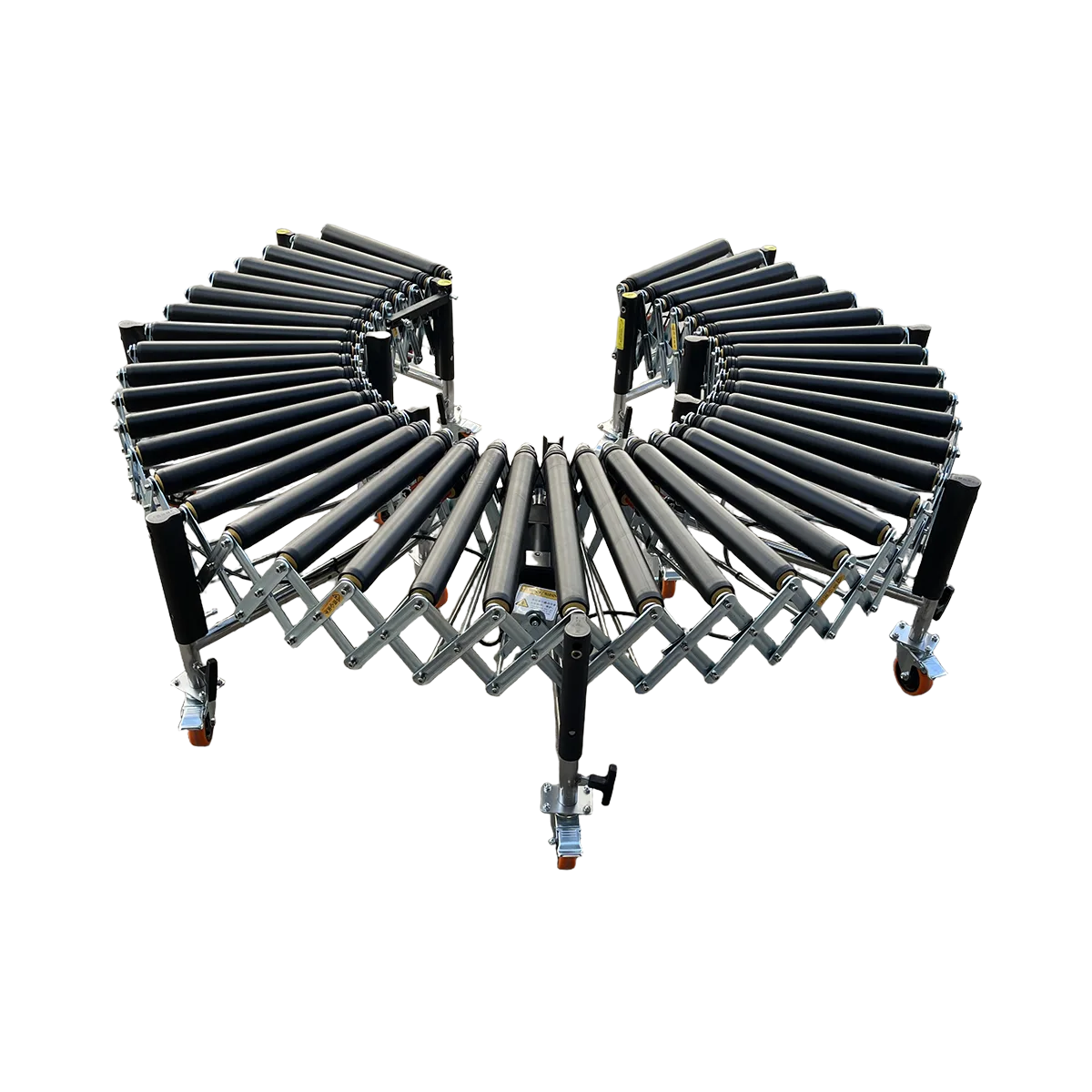

Telescopic Loading and Unloading Conveyor Technology: Ultimate Reach

When maximum extension becomes absolutely critical, nothing matches telescopic loading and unloading conveyor capabilities! These engineering marvels transform from compact storage configurations into impressively extended material handling pathways reaching deep within truck trailers or container interiors.

Multi-Section Loading and Unloading Conveyor Design

Naili offers telescopic loading and unloading conveyor systems across various configurations addressing diverse operational requirements. Each design delivers exceptional performance through thoughtful engineering:

| Configuration | Collapsed Length | Maximum Extended Length | Load Capacity |

| 2-Section | 3000-7000mm | 5000-13000mm | 80 kg/m |

| 3-Section | 4000-7000mm | 9000-15500mm | 80 kg/m |

| 4-Section | 5000-8000mm | 14000-25000mm | 80 kg/m |

| 5-Section | 6000-7000mm | 22000-24000mm | 80 kg/m |

These impressive loading and unloading machines virtually eliminate manual handling requirements throughout truck loading/unloading processes! Workers position systems at trailer entrances allowing products flowing directly between vehicles and warehouse floors without intermediate handling steps. This approach dramatically increases throughput capabilities while simultaneously reducing labor requirements and worker fatigue factors.

Engineering Excellence in Loading and Unloading Conveyors

Behind telescopic loading and unloading conveyor performance stands extraordinary engineering addressing countless operational challenges through innovative design approaches:

- Precision nested sections maintaining perfect alignment throughout extension movements

- High-strength steel construction supporting substantial loads without deflection concerns

- Integrated drive systems powering belt movement independently from extension mechanisms

- Sophisticated control systems allowing simultaneous operation of multiple functions

- Cable drag chains maintaining electrical connections throughout extension movements

Loading dock managers report exceptional reliability despite demanding operational environments! These sophisticated loading and unloading conveyor systems frequently deliver years dependable service despite constant usage throughout multi-shift operations—an impressive testament toward design quality and manufacturing excellence.

Loading and Unloading Conveyor Customization Capabilities

Modern distribution operations frequently require specialized equipment addressing unique facility characteristics. Naili telescopic loading and unloading conveyors accommodate these requirements through numerous customization options:

- Hydraulic lift capabilities adjusting operating angles addressing various vehicle heights

- Operator platforms facilitating manual sorting/scanning activities during loading processes

- Adjustable speed controls accommodating diverse product characteristics

- Electronic casters providing powered positioning capabilities within large facilities

- Product counters tracking throughput metrics automatically during operation

- Variable section lengths matching specific facility dimensional requirements

These adaptation possibilities ensure perfect system alignment with operational requirements rather than forcing process modifications accommodating equipment limitations. This philosophy maximizes productivity improvements while minimizing implementation challenges throughout transition processes.

Loading and Unloading Conveyor Integration Excellence: Creating Seamless Systems

Modern material handling operations rarely rely upon single equipment types throughout entire processes. Naili loading and unloading conveyors integrate beautifully with complementary systems creating comprehensive material movement solutions.

Loading and Unloading Conveyor Gravity System Compatibility

Strategic combinations utilizing powered sections where necessary while implementing gravity components elsewhere optimize operational efficiency while minimizing energy consumption. Naili hydraulic loading and unloading conveyor systems specifically designed accepting various gravity extensions:

| Hydraulic Model | Compatible Extensions | Maximum Extended Length |

| Large | (9 sections) | 18.9 meters |

| Large | 38mm (7 sections) | 13.6 meters |

| Large | 50mm Gravity Roller (8 sections) | 12 meters |

| Medium | Gravity Skate Wheel (5-6 sections) | 10.5-12.6 meters |

| Small | Gravity Skate Wheel (5 sections) | 10.5 meters |

These thoughtful compatibility considerations allow operations creating optimized material flow pathways utilizing appropriate technologies throughout different process segments. This approach maximizes cost-effectiveness while ensuring perfect performance characteristics addressing specific handling requirements throughout various facility areas.

Loading and Unloading Conveyor Facility Layout Optimization

Effective loading and unloading conveyor implementation demands thoughtful planning aligning equipment capabilities with architectural constraints and process requirements. Naili systems include numerous features facilitating optimal integration:

- Adjustable leg heights accommodating various dock configurations

- Compact storage dimensions minimizing space requirements when inactive

- Multiple width options matching specific product characteristics

- Curved segment compatibility navigating around facility obstacles

- Standardized connection points ensuring smooth transfers between sections

Facility engineers appreciate these considerations during implementation planning! Their flexibility allows creating optimized material flow pathways without expensive building modifications or process compromises frequently required with less adaptable equipment alternatives.

Loading and Unloading Conveyor Control System Coordination

Modern operations frequently implement integrated control mechanisms coordinating multiple equipment components simultaneously. Naili loading and unloading conveyors feature control compatibility with:

- Warehouse management systems directing product routing automatically

- Production scheduling software coordinating manufacturing and shipping processes

- Vehicle detection systems activating equipment when trucks arrive at docks

- Barcode scanning interfaces directing packages toward appropriate destinations

- Central monitoring platforms tracking equipment status throughout facilities

These integration capabilities transform individual machines into comprehensive material handling solutions addressing entire process requirements rather than isolated movement segments. Their implementation frequently yields productivity improvements substantially exceeding expectations based upon individual component specifications alone.

Loading and Unloading Conveyor Durability Factors: Built for Demanding Environments

Loading dock environments represent material handling’s ultimate durability challenge. Naili loading and unloading conveyor systems excel through robust construction specifically engineered withstanding punishing operational conditions.

Loading and Unloading Conveyor Material Selection Excellence

Component quality dramatically impacts equipment longevity within demanding applications. Naili loading and unloading conveyors feature thoughtfully selected materials appropriate for specific functional requirements:

- Q345 high-strength steel providing exceptional structural integrity

- 201 stainless steel components preventing corrosion within harsh environments

- Industrial-grade bearings ensuring smooth operation despite continuous usage

- Wear-resistant belt materials maintaining performance throughout extended lifespan s

- Surface treatments protecting against environmental factors throughout operational lives

Maintenance managers report dramatically reduced component replacement requirements compared with lesser alternatives! These quality differences translate directly toward improved uptime statistics and reduced operational interruptions throughout extended equipment lifespans.

Thoughtful Loading and Unloading Conveyor Engineering Details

Beyond basic material quality, numerous design elements contribute toward exceptional durability within demanding operational environments:

- Reinforced frame connections preventing alignment shifts during usage

- Protected electrical components preventing damage from environmental factors

- Oversized drive mechanisms operating below maximum capacity ratings

- Accessibility considerations simplifying maintenance procedures

- Standardized component selections facilitating replacement when eventually required

These seemingly minor considerations combine creating remarkably durable loading and unloading conveyor equipment capable withstanding years reliable service despite punishing operational conditions. Their implementation demonstrates deep understanding regarding real-world application challenges rather than merely theoretical engineering concepts.

Loading and Unloading Conveyor Preventive Maintenance Simplicity

Even exceptional equipment eventually requires service attention ensuring continued optimal performance. Naili loading and unloading conveyor systems feature numerous design elements simplifying these requirements:

- Lubrication points clearly identified facilitating routine service procedures

- Tension adjustment mechanisms easily accessible maintaining optimal belt performance

- Quick-release belt connections expediting replacement when eventually necessary

- Standardized bearing sizes simplifying component inventories

- Modular construction allowing selective component replacement without complete disassembly

Maintenance technicians particularly appreciate these considerations! Routine service procedures typically require minimal time investment while delivering maximum performance impact—an important factor within continuously operating distribution environments where extended downtime creates significant operational challenges.

Loading and Unloading Conveyor Return on Investment Analysis

Equipment acquisition decisions increasingly rely upon comprehensive financial analysis extending far beyond initial purchase considerations. Naili loading and unloading conveyors deliver exceptional return metrics through multiple impact areas.

Loading and Unloading Conveyor Labor Efficiency Improvements

Manual loading/unloading operations consume substantial workforce resources while creating significant injury risks. Automated loading and unloading conveyor alternatives dramatically improve productivity metrics through:

- Throughput capacity increases frequently exceeding 50% following implementation

- Personnel requirement reductions allowing staff reallocation toward value-adding activities

- Fatigue factor elimination maintaining consistent performance throughout entire shifts

- Injury reduction decreasing workers’ compensation costs and lost productivity

- Training requirement simplification reducing onboarding timeframes for new personnel

Operations transitioning from manual methods typically report comprehensive labor cost reductions between 30-60% dependent upon specific application characteristics! These improvements alone frequently justify loading and unloading conveyor investment within surprisingly short timeframes regardless of additional benefits realized.

Loading and Unloading Conveyor Operational Impact Factors

Beyond direct labor considerations, numerous operational improvements contribute toward favorable financial outcomes:

- Increased vehicle turnaround speeds improving transportation asset utilization

- Reduced product damage decreasing replacement costs and customer satisfaction impacts

- Improved inventory accuracy through consistent handling procedures

- Enhanced process predictability facilitating improved scheduling capabilities

- Extended operational windows through reduced physical limitations

managers report comprehensive operational cost reductions averaging 25-40% following loading and unloading conveyor implementation! These improvements dramatically impact bottom-line performance while simultaneously enhancing customer satisfaction metrics through improved service consistency and reduced error rates.

Loading and Unloading Conveyor Equipment Longevity Advantages

Quality equipment delivers exceptional lifespan characteristics dramatically enhancing long-term financial performance. Naili loading and unloading conveyors typically provide:

- 10+ year operational lifespans within normal usage environments

- Minimal component replacement requirements throughout service periods

- Reduced maintenance labor demands compared with lower-quality alternatives

- Extended warranty coverage protecting initial investments

- Excellent parts availability ensuring continued serviceability throughout equipment lives

Financial analysis comparing quality loading and unloading conveyor systems against lower-cost alternatives typically reveals dramatic total ownership cost advantages despite higher initial acquisition investments! This long-term perspective increasingly influences purchasing decisions as organizations adopt more sophisticated capital equipment evaluation methodologies.

FAQ

Can loading and unloading conveyors handle items of various shapes and sizes?

Absolutely! Systems accommodate most boxed products through proper configuration choices. Especially challenging items might require specialized roller surfaces or belt materials depending upon specific characteristics.

What maintenance challenges should we anticipate with loading and unloading conveyors?

Remarkably few! Routine lubrication, occasional belt tension adjustments and periodic alignment verification typically cover everything. Powered systems benefit from annual motor/gearbox inspections while hydraulic versions need occasional fluid level checks.

How quickly can these loading and unloading conveyor systems be repositioned between truck loading operations?

Lightning fast! Most models feature quick-lock casters allowing single-worker repositioning within minutes. Larger telescopic units might require two personnel but still accomplish moves within 5-10 minutes typically.

Will loading and unloading conveyors work with different truck heights?

Definitely! Hydraulic systems adjust accommodating various vehicle heights ranging from small delivery vans through full-height trailers. Telescopic models similarly feature height adjustment capabilities ensuring perfect alignment with diverse vehicles.

What’s the typical ROI timeframe for loading and unloading conveyor implementation?

Remarkably quick! Most operations report complete investment recovery within 9-18 months through labor savings, injury reductions and throughput improvements. High-volume operations sometimes achieve payback within 6 months following implementation.