Powered Conveyor Manufacturer

Home > Powered Conveyor

Unlike passive gravity systems, powered conveyors deliver consistent, controlled movement regardless of package weight, size, or incline requirements.

Our Powered Conveyor Products

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 6000 | 16000 | 22000 |

| 7000 | 17000 | 24000 |

Flat-bottomed Goods

Bagged Goods

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 5000 | 9000 | 14000 |

| 6000 | 12000 | 18000 |

| 7000 | 14000 | 21000 |

| 8000 | 17000 | 25000 |

Flat-bottomed Goods

Bagged Goods

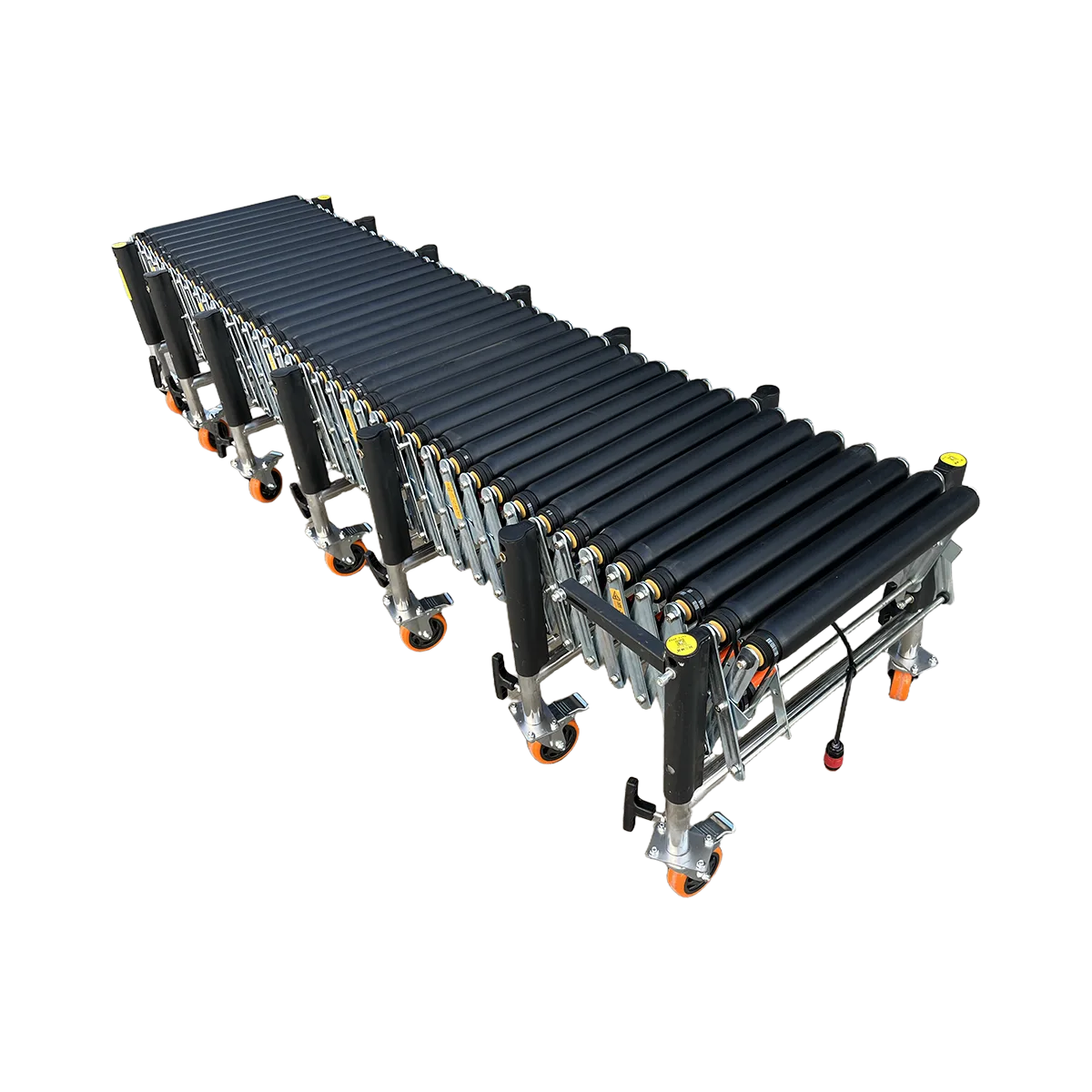

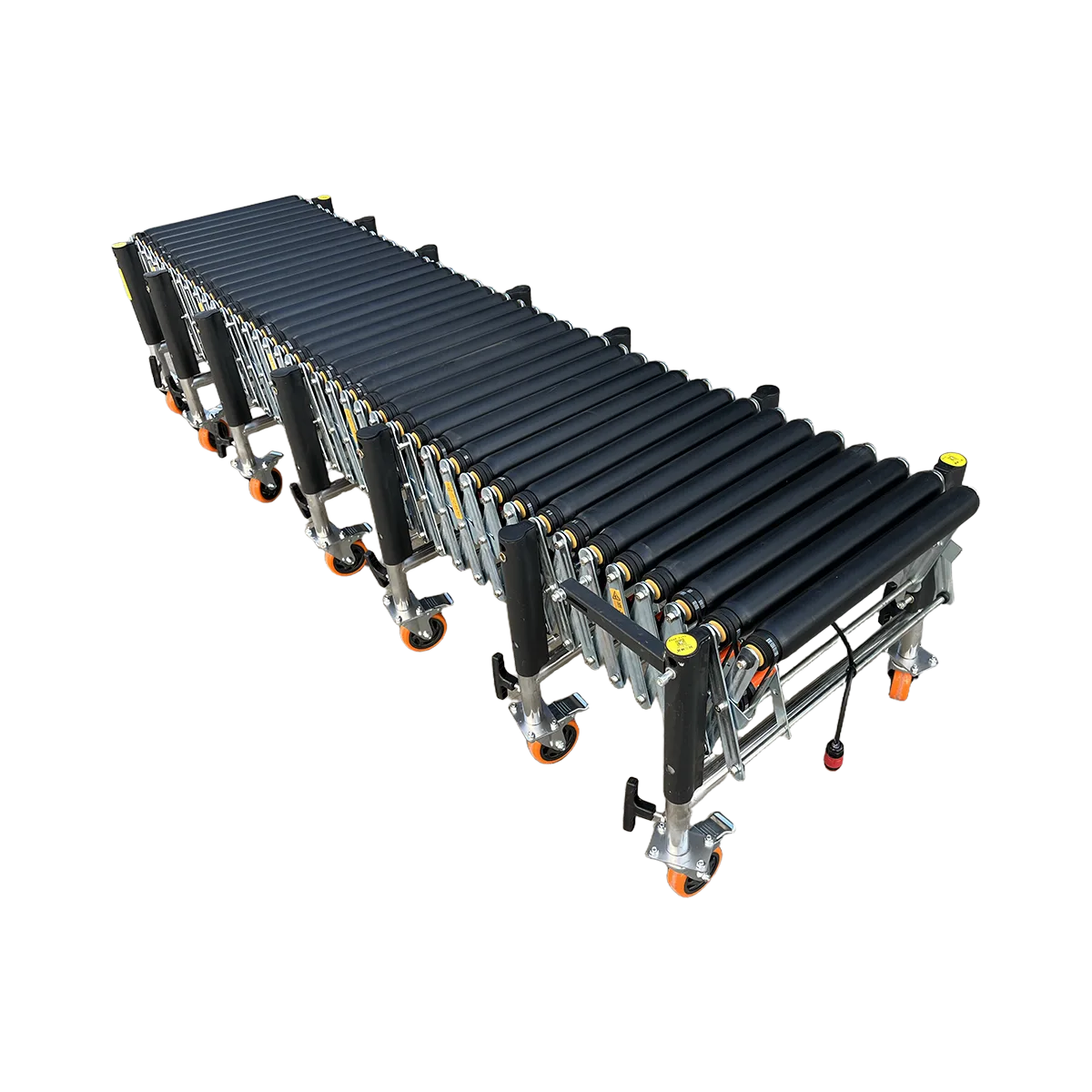

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 4000 | 5000 | 9000 |

| 5000 | 7000 | 12000 |

| 6000 | 8000 | 14000 |

| 6000 | 8500 | 14500 |

| 7000 | 9000 | 16000 |

| 7000 | 9500 | 16500 |

Flat-bottomed Goods

Bagged Goods

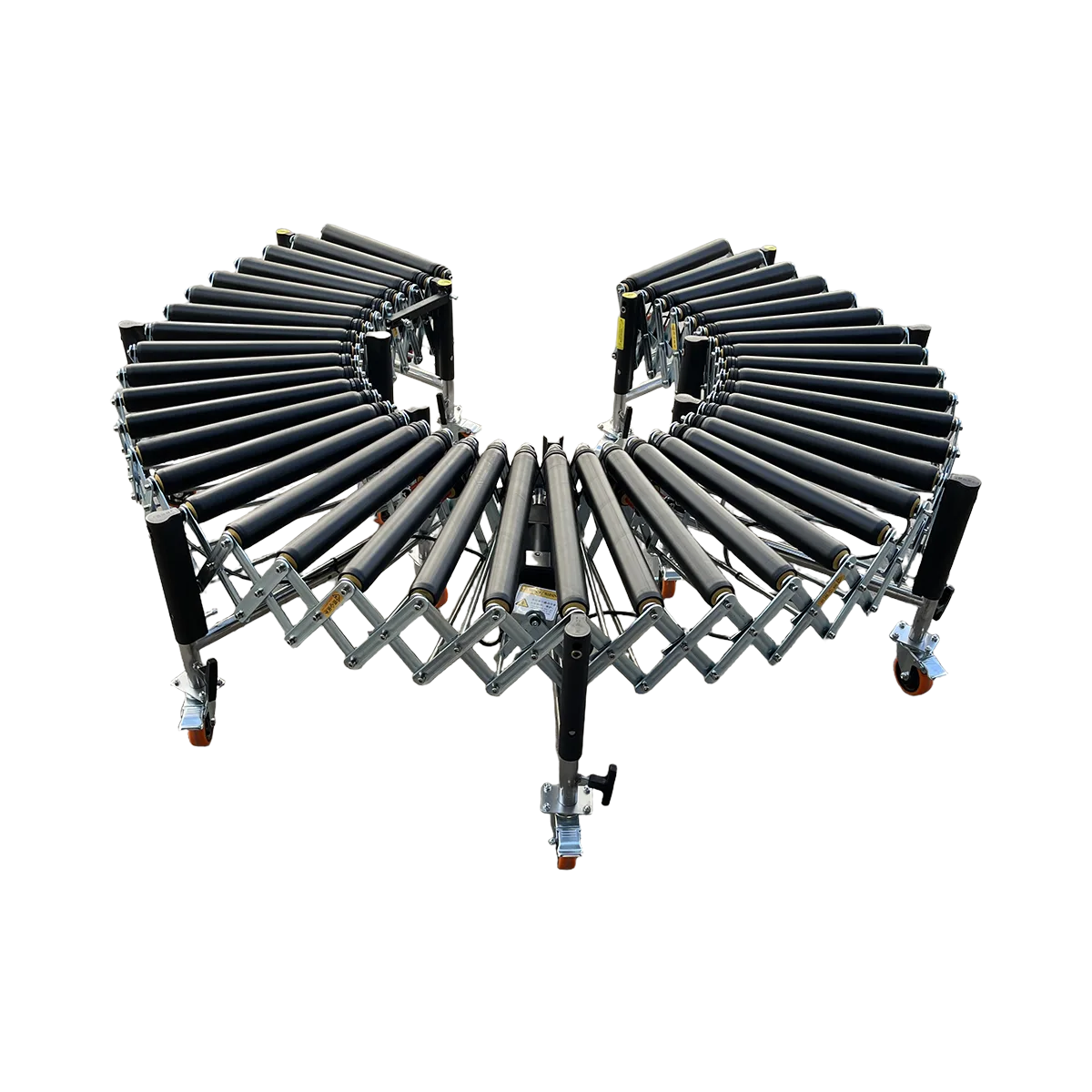

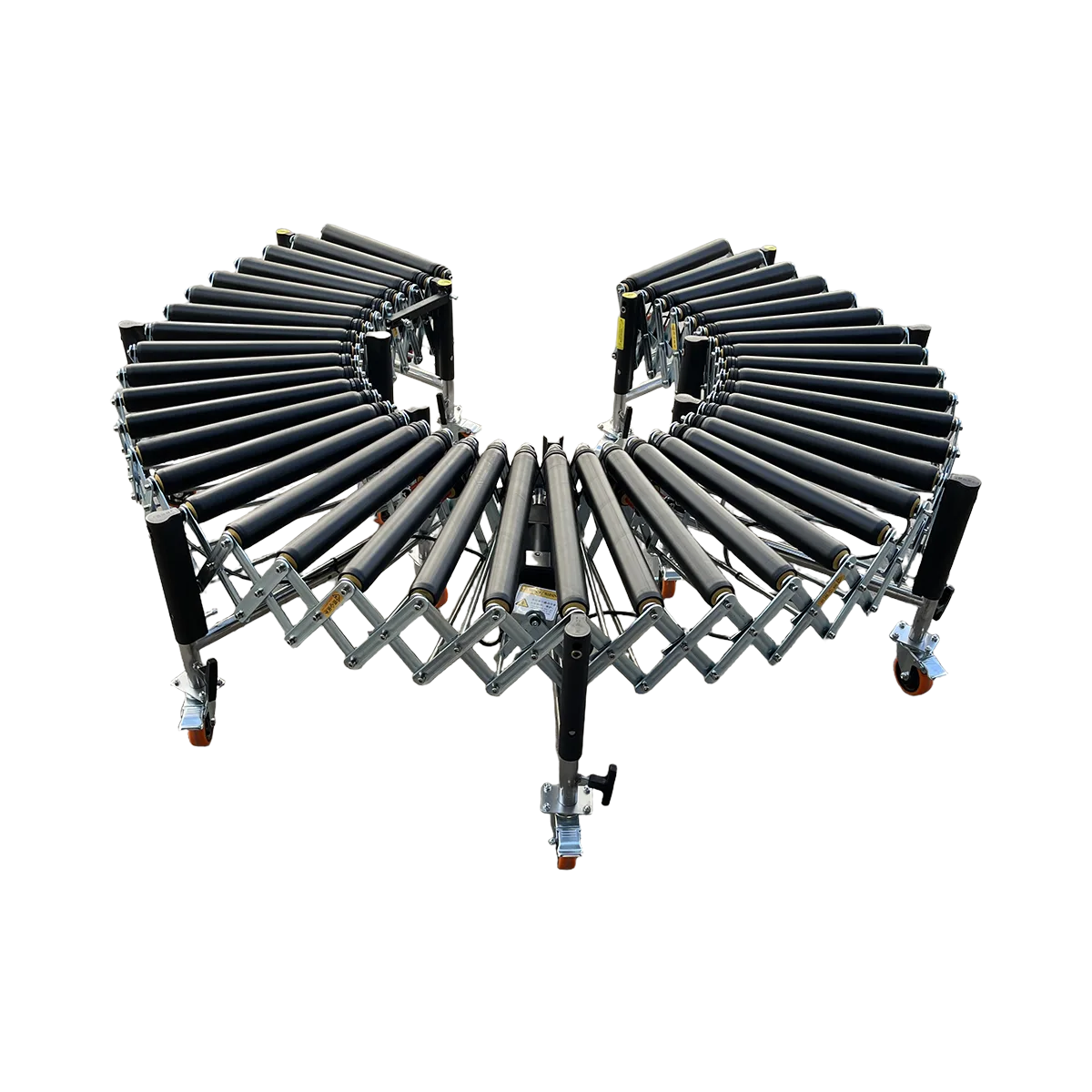

60 kg/m

Length Range

| Length A: Base length (mm) | Length B: Extension length (mm) | Length C: Fully extended length (mm) |

|---|---|---|

| 3000 | 2000 | 5000 |

| 4000 | 3000 | 7000 |

| 5000 | 4000 | 9000 |

| 6000 | 5000 | 11000 |

| 7000 | 6000 | 13000 |

Flat-bottomed Goods

Bagged Goods

7900 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

7000 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

5400 mm

80 kg/m

Flat-bottomed Goods

Bagged Goods

3700 mm

50 kg/m

Flat-bottomed Goods

Bagged Goods

560 mm

1100 mm

120 kg/m

Flat-bottomed Goods

Bagged Goods

525 mm

1500 mm

80 kg/m

Flat-bottomed Goods

700 mm

2000 mm

100 kg/m

Flat-bottomed Goods

1050 mm

3000 mm

80 kg/m

Flat-bottomed Goods

Transform your facility’s material handling capabilities with advanced powered conveyor technology! Unlike passive gravity systems, powered conveyors deliver consistent, controlled movement regardless of package weight, size, or incline requirements. Naili’s comprehensive powered conveyor lineup includes versatile multi-wedge belt driven solutions, specialized O-shaped belt systems, rubber roller configurations for delicate handling, and extraordinary telescopic units stretching up to 25 meters! These dynamic systems eliminate flow bottlenecks, reduce manual handling requirements, and dramatically increase throughput capacity across distribution centers, manufacturing facilities, and logistics operations. Each powered conveyor features precision engineering focusing on operational reliability, maintenance simplicity, and seamless integration with existing material handling equipment.

Multi-Wedge Belt Driven Conveyors: Superior Performance Through Design Excellence

When material handling operations demand consistent product flow regardless of weight variations or position, Naili multi-wedge belt driven powered conveyors deliver exceptional reliability.

Telescopic Capability in 2-Meter Configurations

Naili’s 2-meter multi-wedge belt driven conveyors provide impressive flexibility through intelligent design:

| Feature | Specification | Benefit |

| Extension Ratio | 2:3 (700mm collapsed to 2000mm extended) | Maximizes available floor space during inactive periods |

| Load Capacity | 100 kg/m | Handles medium-duty applications with substantial margin |

| Operational Speed | 40 m/min | Maintains efficient throughput for high-volume operations |

| Roller Construction | 50mm diameter, ≥1.5mm thickness | Provides durability while ensuring smooth product flow |

| Available Widths | 500/600/800mm | Accommodates various product dimensions |

These versatile powered conveyors feature precision-engineered components ensuring reliable operation throughout demanding applications. Their robust 35×35mm stainless steel frame construction withstands industrial environments while providing necessary stability under load conditions.

Operations managers particularly appreciate the adjustable height support legs (450-1500mm range) allowing perfect ergonomic positioning regardless of facility requirements. The compact collapsed configuration minimizes storage space requirements when not actively used—a valuable characteristic within space-constrained facilities.

Extended Reach with 3-Meter Sections

When additional extension capabilities become necessary, Naili’s 3-meter multi-wedge belt driven powered conveyors provide exceptional reach:

| Feature | Specification | Benefit |

| Extension Ratio | 1:3 (1050mm collapsed to 3000mm extended) | Delivers nearly three times operational length from compact storage |

| Load Capacity | 80 kg/m | Handles most distribution center applications effectively |

| Operational Speed | 40 m/min | Maintains consistent throughput requirements |

| Roller Construction | 50mm diameter, ≥1.5mm thickness | Ensures reliable product transport throughout extended lifespans |

| Available Widths | 500/600/800mm | Accommodates various package dimensions |

These extended-reach powered conveyors maintain identical reliability characteristics despite their impressive extension capabilities. The thoughtful engineering approach ensures consistent performance throughout the entire extended length without compromising structural integrity or operational reliability.

Facility engineers appreciate the intelligent drive design incorporating multi-wedge belts providing superior power transmission with minimal maintenance requirements. This approach dramatically extends service intervals while reducing operational interruptions compared with traditional chain-driven alternatives.

O-Shaped Belt Technology: Specialized Handling Solutions

Some material handling applications require specialized performance characteristics addressing unique operational challenges. Naili’s O-shaped belt driven powered conveyors deliver exceptional capabilities through innovative design:

| Feature | Specification | Benefit |

| Extension Ratio | 1:3 (525mm collapsed to 1500mm extended) | Creates substantial operational reach from minimal storage footprint |

| Load Capacity | 80 kg/m | Handles medium-duty applications effectively |

| Operational Speed | 40 m/min | Maintains efficient product flow rates |

| Roller Construction | 50mm diameter, ≥1.5mm thickness | Provides excellent durability within demanding environments |

| Drive Technology | Individual O-shaped belts | Simplifies maintenance while improving performance reliability |

These specialized powered conveyors excel within applications requiring enhanced product grip during transportation. The unique O-shaped belt design provides superior traction control particularly valuable when handling products with challenging surface characteristics or irregular shapes.

Maintenance technicians appreciate the simplified service procedures! Individual belt replacement capabilities minimize downtime requirements when component replacement eventually becomes necessary—dramatically improving operational availability compared with systems requiring complete belt removal during service procedures.

Rubber Roller Conveyor Systems: Protecting Sensitive Products

Handling delicate or finished products requires specialized equipment preventing damage during transportation. Naili’s rubber roller powered conveyors deliver exceptional product protection:

| Feature | Specification | Benefit |

| Extension Ratio | 1:3 (560mm collapsed to 1100mm extended) | Provides operational flexibility while minimizing storage requirements |

| Load Capacity | 120 kg/m | Offers industry-leading capacity despite gentle handling characteristics |

| Operational Speed | 40 m/min | Maintains necessary throughput for high-volume operations |

| Roller Construction | 54mm diameter rubber coating | Provides cushioned contact preventing product damage |

| Available Widths | 500/600/800mm | Accommodates various product dimensions |

These specialized powered conveyors particularly excel within operations handling consumer electronics, packaged goods with glossy finishes, or any products susceptible to handling damage. Their unique rubber roller design prevents scratching, scuffing or impact damage frequently associated with harder roller surfaces.

Quality control managers report dramatic reduction in handling-related damage claims following implementation! The gentle product contact significantly improves damage prevention metrics while maintaining necessary throughput capabilities required within high-volume distribution environments.

Telescopic Powered Conveyors: Ultimate Reach and Flexibility

When material handling operations demand extraordinary reach capabilities with powered reliability, Naili’s telescopic conveyor systems deliver unmatched performance through sophisticated engineering.

Multi-Section Design Excellence

Naili telescopic powered conveyors adapt to diverse operational requirements through multiple configuration options:

| Configuration | Collapsed Length | Maximum Extended Length | Load Capacity |

| 2-Section | 3000-7000mm | 5000-13000mm | 80 kg/m |

| 3-Section | 4000-7000mm | 9000-15500mm | 80 kg/m |

| 4-Section | 5000-8000mm | 14000-25000mm | 80 kg/m |

| 5-Section | 6000-7000mm | 22000-24000mm | 80 kg/m |

These extraordinary powered conveyors revolutionize vehicle loading/unloading operations through their remarkable extension capabilities! Products flow continuously from facility areas directly into truck trailers or shipping containers without intermediate handling requirements—dramatically reducing labor costs while improving throughput metrics.

Advanced Engineering Features

Behind telescopic powered conveyor performance stands sophisticated engineering addressing numerous operational challenges:

- Variable frequency drives providing adjustable speeds between 10-40 m/min

- Precision-nested steel sections maintaining perfect alignment throughout extension

- 3mm PVK impact-resistant composite belting ensuring reliable product transport

- Integrated LED lighting systems improving visibility within trailer interiors

- Heavy-duty drive rollers with 10mm rubber coating ensuring reliable operation

- Cable drag chains maintaining electrical connections during extension/retraction

These advanced engineering elements create remarkably capable material handling systems addressing demanding operational environments. The thoughtful design approach ensures reliable performance despite challenging conditions frequently encountered within loading dock environments.

Customization Options for Operational Excellence

Modern logistics operations frequently require specialized equipment addressing unique facility characteristics. Naili telescopic powered conveyors accommodate these requirements through numerous configuration options:

- Hydraulic lifting mechanisms adjusting operating angles between 0-3.5° degrees

- Operator platforms facilitating scanning/sorting during loading procedures

- Electric positioning casters improving mobility within large facilities

- Product counting systems tracking throughput metrics automatically

- Multiple width options accommodating diverse product dimensions

These adaptation capabilities ensure perfect alignment between equipment capabilities and operational requirements. This thoughtful approach maximizes productivity improvements while minimizing implementation challenges throughout system deployment processes.

Engineering Quality in Every Powered Conveyor Component

Naili powered conveyors deliver exceptional performance through meticulous component selection and manufacturing excellence. Every system features:

Premium Material Selection

Component quality dramatically impacts equipment reliability within demanding applications. Naili powered conveyors feature thoughtfully selected materials appropriate for specific operational requirements:

- Q345 high-strength steel frames providing exceptional structural integrity

- 201 stainless steel components preventing corrosion within variable environments

- Industrial-grade bearings ensuring smooth operation throughout extended service periods

- Precision-engineered drive systems maintaining consistent performance under load

- Surface electrostatic spray treatments protecting against environmental factors

Maintenance managers report significantly reduced component replacement requirements compared with alternative solutions! These quality differences translate directly toward improved uptime statistics—a critical factor within continuously operating logistics environments where equipment reliability directly impacts operational profitability.

Simplified Maintenance Requirements

Even exceptional equipment eventually requires service attention ensuring continued optimal performance. Naili powered conveyors feature numerous design elements simplifying these requirements:

- Accessible drive components facilitating inspection without disassembly

- Standardized bearing sizes simplifying replacement parts inventory

- Quick-release belt tensioners expediting adjustment procedures

- Modular construction allowing selective component replacement

- Comprehensive documentation supporting maintenance protocols

These thoughtful design considerations minimize service time requirements while maximizing equipment availability throughout operational lifespans. Operations particularly appreciate these characteristics within high-volume environments where throughput interruptions create significant business impacts.

Integrated Control Systems for Operational Excellence

Modern material handling requires sophisticated control capabilities ensuring perfect operational coordination. Naili powered conveyors include advanced control features:

- Variable frequency drives allowing precise speed adjustments (0.75-3.7kW depending on model)

- Forward/reverse operation providing operational flexibility

- Emergency stop functions ensuring workplace safety

- Speed control capabilities adapting to various product requirements

- Compatibility with warehouse management systems enabling automated operation

These control capabilities transform individual powered conveyor sections into comprehensive material handling solutions addressing entire process requirements. Their implementation frequently yields productivity improvements substantially exceeding expectations based upon individual component specifications alone.

Return on Investment Analysis

Equipment acquisition decisions increasingly rely upon comprehensive financial analysis beyond initial purchase considerations. Naili powered conveyors deliver exceptional return metrics through multiple impact areas.

Labor Efficiency Impacts

Manual material handling consumes substantial workforce resources while creating significant injury risks. Powered conveyor alternatives dramatically improve productivity metrics through:

- Throughput capacity increases frequently exceeding 60% following implementation

- Personnel requirement reductions allowing staff reallocation toward value-adding activities

- Fatigue factor elimination maintaining consistent performance throughout entire shifts

- Repetitive motion injury prevention reducing workers’ compensation costs

- Simplified training requirements addressing labor shortage challenges

Operations transitioning from manual handling methods typically report comprehensive labor cost reductions between 40-70% dependent upon specific application characteristics! These improvements alone frequently justify implementation investments regardless of additional benefits realized through improved operational metrics.

Operational Efficiency Factors

Beyond direct labor considerations, numerous operational improvements contribute toward favorable financial outcomes:

- Increased processing speeds improving overall facility throughput

- Reduced product damage decreasing replacement costs and customer satisfaction impacts

- Improved inventory accuracy through consistent handling procedures

- Enhanced process predictability facilitating improved scheduling capabilities

- Extended operational windows through reduced physical limitations

Logistics managers report comprehensive operational cost reductions averaging 30-45% following implementation! These improvements dramatically impact bottom-line performance while simultaneously enhancing customer satisfaction metrics through improved service consistency and reduced error rates.

FAQ

How does powered conveyor speed impact operational throughput?

Standard 40 m/min speed handles most applications efficiently. Variable frequency drives allow precise speed adjustments between 10-40 m/min accommodating specific product requirements. Most facilities achieve optimal results at 30-35 m/min balancing throughput against handling safety.

What maintenance schedule applies to powered conveyor systems? Standard requirements include monthly visual inspections, quarterly belt tension verification, and semi-annual bearing lubrication. Multi-wedge systems typically require belt replacement every 3-5 years depending on usage patterns. Electrical components should receive annual inspection ensuring optimal performance.

Can powered conveyors handle irregularly shaped products?

Absolutely! Roller spacing accommodates most product dimensions. Particularly challenging items perform best on rubber roller versions providing enhanced surface contact. Very unusual shapes might benefit from shallow trays ensuring stable transport across powered sections.

How do I determine the appropriate powered conveyor width for my operation?

Select width exceeding your largest typical product by minimum 50mm on each side. Standard 600mm width handles most distribution applications efficiently. Operations processing predominantly small items might select 500mm, while larger package handling typically requires 800mm configurations.

What’s the typical ROI timeline for powered conveyor implementation?

Most operations achieve complete investment recovery within 10-18 months through labor savings, throughput improvements and damage reduction. High-volume facilities sometimes report payback periods as short as 7 months following installation. The most significant financial benefits typically come from labor efficiency improvements and throughput capacity increases.